Hydrophobic and oleophobic open-cell foam material and preparation method thereof

An open-cell foam and oleophobic technology, which is applied in the field of open-cell foam materials and their preparation, to achieve the effects of simple operation, environmentally friendly process, and good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

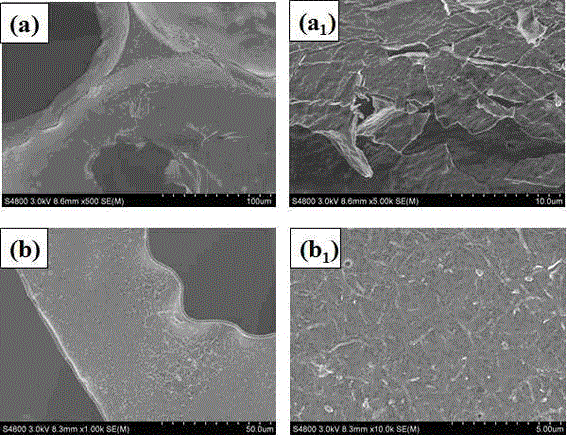

[0039] 1) Preparation of graphene oxide modified with fluorine-containing silane coupling agent: Add graphene oxide into ethanol, ultrasonically disperse to prepare a graphene oxide ethanol solution with a concentration of 1mg / mL, and then add ammonia water dropwise to adjust to pH=8.5; Transfer the above solution to a three-necked flask; take heptadecafluorodecyltrimethoxysilane coupling agent and dilute it with a small amount of ethanol, the mass ratio of fluorine-containing silane to graphene oxide is 1:1, and mix under reflux at 60°C The fluorine-containing silane coupling agent diluted with ethanol was added dropwise into the graphene oxide solution, and refluxed for 24 h. Suction filter, wash with ethanol, and use directly or after drying for later use.

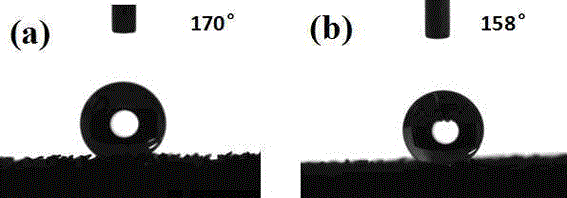

[0040] 2) Preparation of polyurethane foam material modified by heptadecafluorodecyltrimethoxysilane coupling agent modified graphene oxide: take 50 ml heptadecafluorodecyltrimethoxysilane coupling agent modified with a...

Embodiment 2

[0044] 1) Preparation of graphene oxide tapes modified with fluorine-containing silane coupling agent: Add graphene oxide tapes into ethanol, ultrasonically disperse to prepare a graphene oxide tape ethanol solution with a concentration of 5 mg / mL, and then add ammonia water dropwise to adjust to pH=9.5; transfer the above solution to a three-necked flask; take a certain amount of heptadecafluorodecyltriethoxysilane coupling agent and dilute it with a small amount of ethanol, the mass ratio of fluorine-containing silane to graphene oxide is 1.5:1 , Add the above-mentioned fluorine-containing silane coupling agent diluted with ethanol dropwise into the graphene oxide solution under reflux and stirring at 60 °C, and reflux for 24 h. Suction filter, wash with ethanol, and use directly or after drying for later use.

[0045] 2) Preparation of heptadecafluorodecyltriethoxysilane coupling agent-modified graphene oxide band-modified polyurethane foam: take 50 ml of heptadecafluorodec...

Embodiment 3

[0049] 1) Preparation of graphene oxide ribbons modified with fluorine-containing silane coupling agent: Add graphene oxide ribbons into ethanol, ultrasonically disperse to prepare graphene oxide ribbon ethanol solution with a concentration of 10 mg / mL, and then add ammonia water dropwise to adjust to pH=10; transfer the above solution to a three-necked flask; take a certain amount of tridecafluorooctyltriethoxysilane coupling agent and dilute it with a small amount of ethanol. The mass ratio of fluorine-containing silane to graphene oxide ribbon is 2: 1. Add the fluorine-containing silane coupling agent diluted with ethanol dropwise into the graphene oxide tape solution at 60 °C under reflux and stirring, and reflux for 24 h. Suction filter, wash with ethanol, and use directly or after drying for later use.

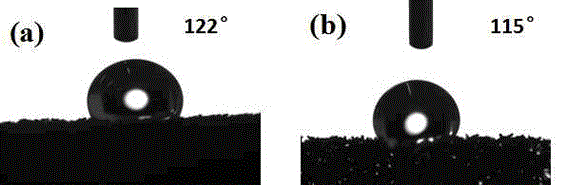

[0050] 2) Preparation of tridecafluorooctyltriethoxysilane coupling agent modified graphene oxide with modified polyurethane foam: take 50 ml of tridecafluorooctyltrieth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com