High temperature chain oil composition and preparation method thereof

A high-temperature chain and oil composition technology, which is applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problems of no innovation in the selection of anti-wear agents, no breakthrough in anti-wear performance, etc. Excellent grinding and lubricating performance, and the effect of reducing the amount of generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

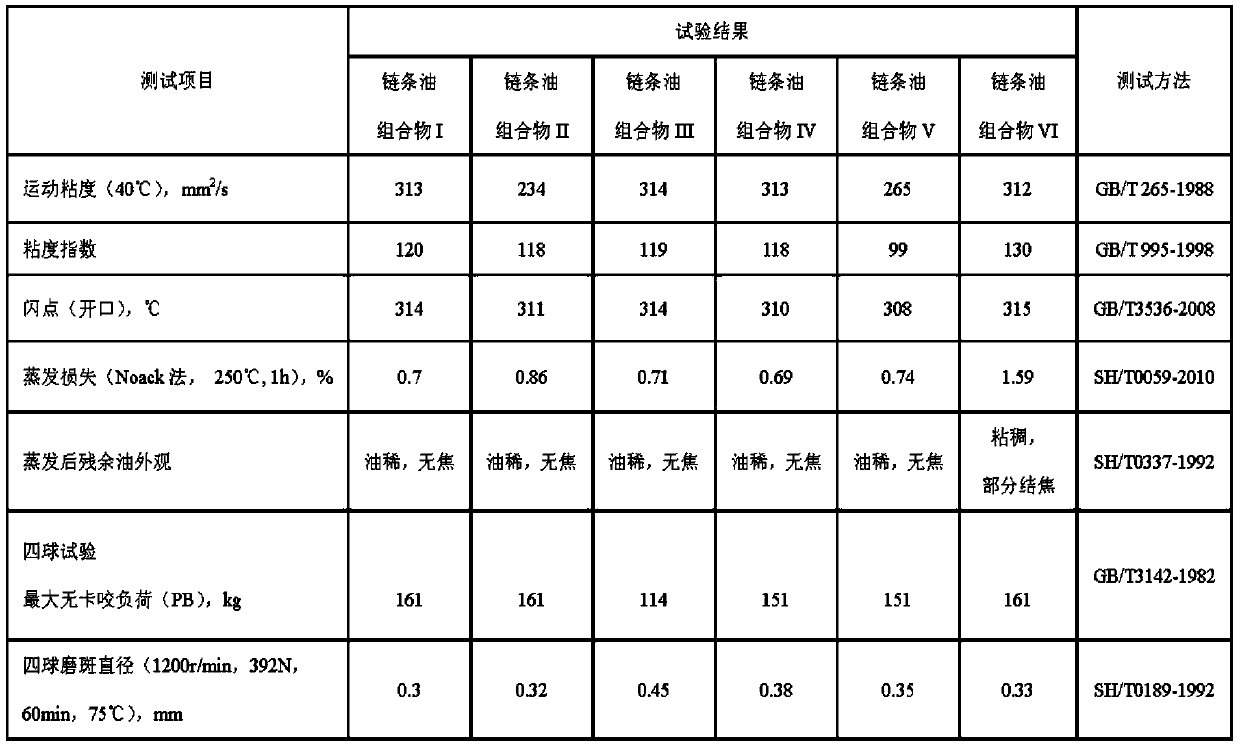

Examples

preparation example Construction

[0052] In addition, the present invention also provides a method for preparing a high temperature chain oil composition, comprising the following steps: weighing each component according to the above ratio, mixing and stirring evenly.

[0053] Preferably, the method includes the following steps: weighing the synthetic ester base oil, viscosity index improver, antioxidant, alkoxyphosphate extreme pressure antiwear agent, oily agent, and preservative according to the stated ratio, Add it into a container, stir evenly at 50-60° C. to obtain a high-temperature chain oil composition.

Embodiment 1

[0056] 69 parts of dipentaerythritol ester DIPE-3 (manufactured by Liaocheng Ruijie Chemical Co., Ltd.), 23.5 parts of trimellitate Emkarate 1938 (manufactured by Croda Chemical Company) and 4.9 parts of viscosity index improver Priolube 3986 (viscosity index of 278, Croda Chemical Company) was added into a 200ml beaker, then 1 part of p-,p-dioctyldiphenylamine antioxidant Irganox L01 (manufactured by Basf Chemical Company), 1 part of P120 Phosphorus Star Extreme Pressure Anti-wear Agent (Shenyang Hualun) were added in turn. Manufactured by Oil Chemicals Co., Ltd.), 0.5 part of oily agent sulfurized olefin Cottonseed Oil T405A (manufactured by Jinzhou Kangtai Lubricating Oil Additive Co., Ltd.), and 0.1 part of anti-corrosion agent alkenyl succinate IrganoxL12 (manufactured by Basf Chemical Company), stirred at 60°C until uniform and transparent to obtain high temperature chain oil composition I.

Embodiment 2

[0058] 59 parts of dipentaerythritol ester DIPE-2 (manufactured by Liaocheng Ruijie Chemical Co., Ltd.), 35 parts of trimellitate Emkarate 1938 (manufactured by Croda Chemical Company) and 4 parts of viscosity index improver Priolube 3986 (viscosity index of 278, Croda Chemical Company) was added into a 200ml beaker, then 0.4 parts of high molecular weight phenolic antioxidant Irganox L115 (manufactured by Basf Chemical Company) containing thioether group, 0.8 parts of P120 Phosphorus Star extreme pressure antiwear agent (Shenyang Hua Lun) were successively added. Manufactured by Oil Chemicals Co., Ltd.), 0.7 parts of oily agent sulfurized olefin Cottonseed Oil T405A (manufactured by Jinzhou Kangtai Lubricating Oil Additives Co., Ltd.), and 0.1 part of anti-corrosion agent alkenyl succinate IrganoxL12 (manufactured by Basf Chemical Company), stirred at 60°C To uniform and transparent, high temperature chain oil composition II is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com