Abrasion-resistant flame-retardant wood plastic and preparation method thereof

A wood-plastic and composite flame retardant technology, applied in the field of materials, can solve problems such as the inability to meet high-end market demands, and achieve obvious economic and social benefits, outstanding wear resistance and flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

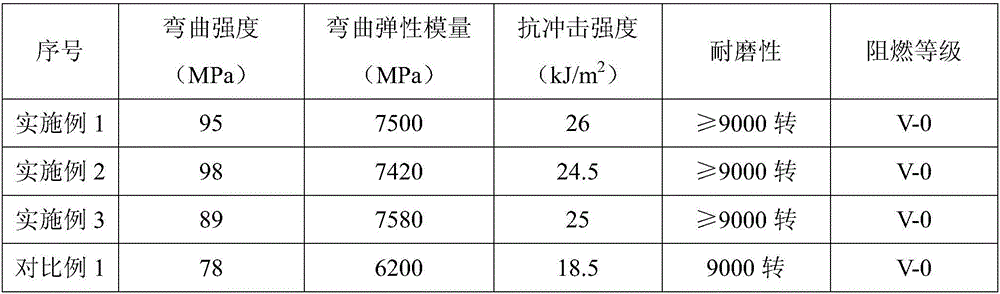

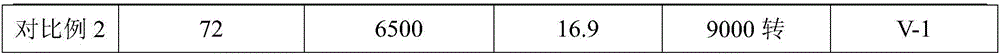

Examples

Embodiment 1

[0022] The wear-resistant and flame-retardant wood plastic of this embodiment includes the following components in parts by weight: 50 parts of modified plant fibers, 40 parts of basalt long fibers, 50 parts of PE, 20 parts of composite flame retardants, 10 parts of lubricants, calcium carbonate 5 parts, 5 parts of silica, 3 parts of montmorillonite, 2 parts of carbon black, 1 part of antioxidant, 0.5 parts of coupling agent and 0.5 parts of pigment.

[0023] Among them, the plant fiber is one or a mixture of corn stalks, wheat straws, chaff husks, peanut shells or wood chips; the composite flame retardant is a compound synthesized by pentaerythritol phosphate and melamine; the lubricant includes stearic acid , calcium stearate, zinc stearate, paraffin wax; the average particle size of silicon dioxide is 80-200nm; the antioxidant is antioxidant 1010; the coupling agent is silane coupling agent.

[0024] The specific preparation method is as follows:

[0025] S1. Modified plan...

Embodiment 2

[0029] The wear-resistant and flame-retardant wood plastic of this embodiment includes the following components in parts by weight: 70 parts of modified plant fibers, 50 parts of basalt long fibers, 70 parts of PE, 30 parts of composite flame retardants, 12 parts of lubricants, calcium carbonate 8 parts, 6 parts of silica, 4 parts of montmorillonite, 3 parts of carbon black, 2 parts of antioxidant, 1 part of coupling agent and 0.7 parts of pigment.

[0030] The specific preparation method is as follows:

[0031] S1. Modified plant fiber: Mix 15 parts of anhydrous magnesium chloride, 15 parts of magnesium sulfate and 30 parts of triglycidyl isocyanurate to make a modifier and place it in a solvent tank, then put the plant fiber into the solvent tank After internal soaking for 8 hours, take it out and dry it naturally for later use;

[0032] S2, granulation: after mixing all raw material components except modified plant fibers (stirring speed during blending is 300-600r / min, mi...

Embodiment 3

[0035] The wear-resistant and flame-retardant wood plastic of this embodiment includes the following components in parts by weight: 80 parts of modified plant fibers, 60 parts of basalt long fibers, 80 parts of PE, 40 parts of composite flame retardants, 15 parts of lubricants, calcium carbonate 10 parts, 8 parts of silica, 5 parts of montmorillonite, 4 parts of carbon black, 3 parts of antioxidant, 1.5 parts of coupling agent and 1 part of pigment.

[0036] The specific preparation method is as follows:

[0037] S1. Modified plant fiber: Mix 20 parts of anhydrous magnesium chloride, 20 parts of magnesium sulfate and 40 parts of triglycidyl isocyanurate to make a modifier and place it in a solvent tank, then put the plant fiber into the solvent tank After internal soaking for 10 hours, take it out and dry it naturally for later use;

[0038] S2, granulation: after mixing all raw material components except modified plant fibers (stirring speed during blending is 300-600r / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com