Method for reinforcing debris flow blocking dam foundation based on micro composite piles

A technology of debris flow and micro-piles, which is applied in infrastructure engineering, construction, etc., can solve the problems of weak foundation bearing capacity, harsh terrain conditions, and difficult foundation treatment of retaining engineering in ditch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

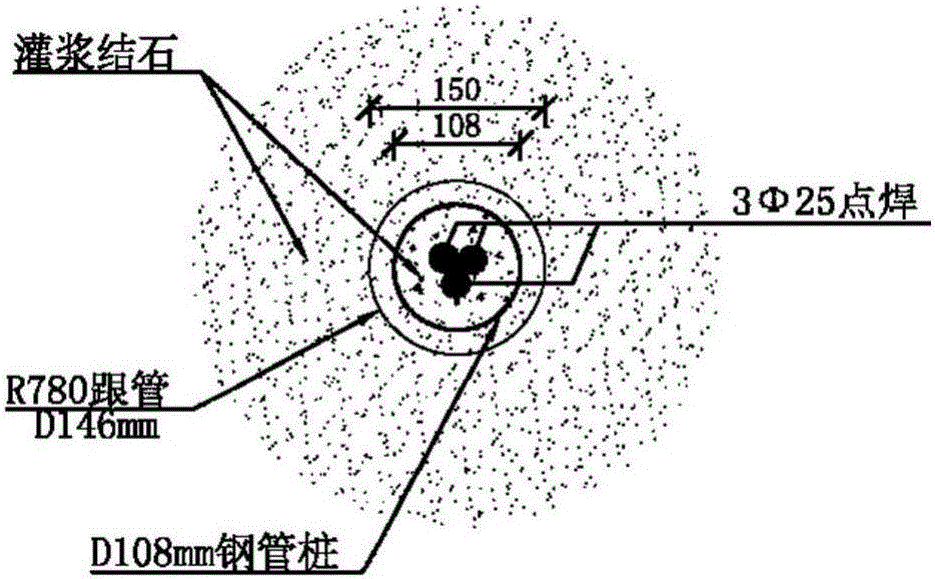

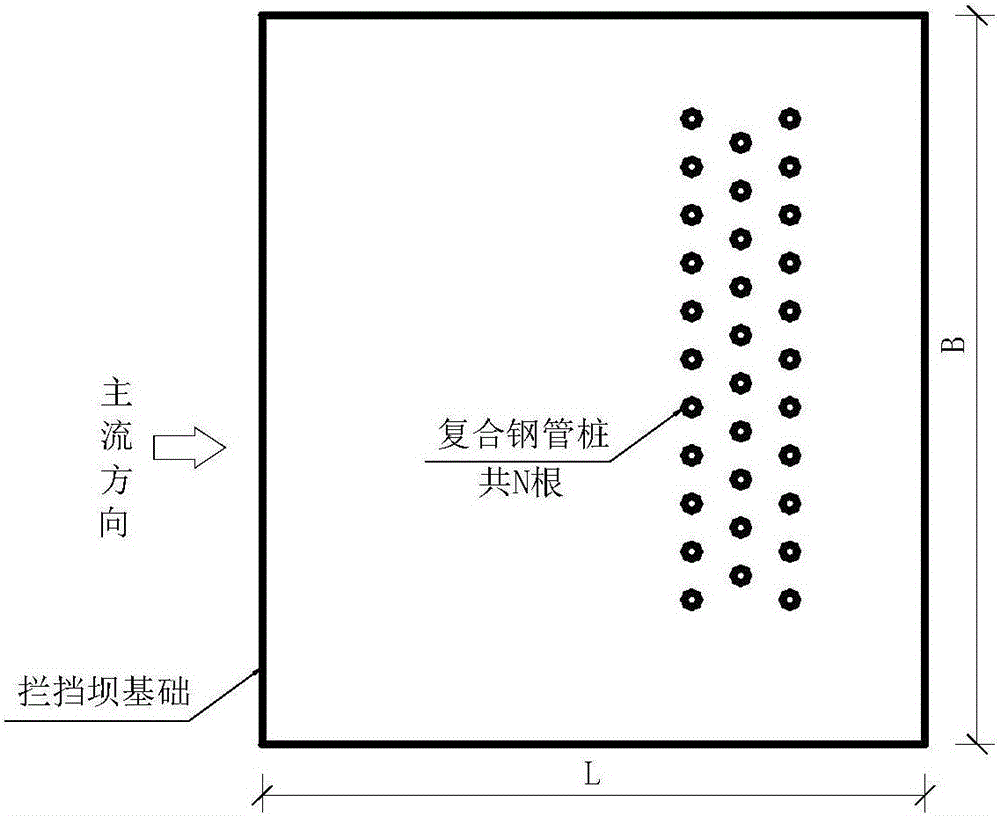

[0043] Implementation cases such as Figure 2-Figure 4

[0044] 1) The longitudinal slope of the ditch bed at the dam site of a debris flow sand control dam is about 350‰, and the ditch bed is rich in deposits. Under the erosion of water flow and debris flow, the ditch bed cuts strongly, and the ditch is in a "V" shape. The material composition is crushed stone interbedded with silty clay, the content of crushed stone is about 40-60%, the general particle size is 15-40cm, the maximum can reach 3.0m, and the bank slope is 15-70°. The mechanical properties of the dam abutment and base soil are as follows: 1) The foundation soil less than 4.0m is slightly dense gravel, and the standard value of N120 impact number is 5.3 blows / 10cm, and the bearing capacity does not meet the requirements of the upper design load. 2) The foundation soil greater than 4.0m is medium-density crushed stone with good stability. The standard value of N120 hammer number is 8.3 blows / 10cm, which has low c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com