Accumulation vertical HEMT device

It is an accumulation type and device technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc. It can solve the problems of increasing the on-resistance of the device and limiting the forward current capability of the device, so as to reduce the on-resistance and improve the forward current drive. Capability, the effect of uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

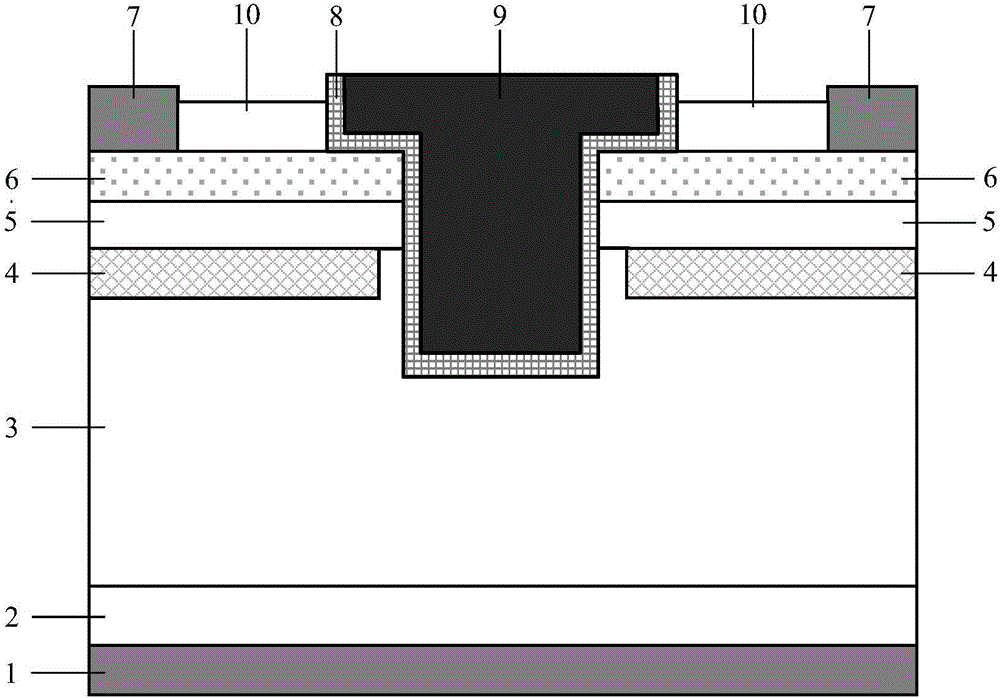

[0033] Compared with Embodiment 1, the insulating gate dielectric 8 of the device in this example presents a stepped shape, and other structures are the same as in Embodiment 1, such as Figure 4 shown. The introduction of the step-shaped insulating gate dielectric 8 can effectively reduce the gate capacitance and improve the dynamic performance of the device, but the accumulation effect of the gate will be weakened.

Embodiment 3

[0035] Compared with Embodiment 1, the insulated gate structure of the device in this example is a split insulated gate structure, and other structures are the same as in Embodiment 1, such as Figure 5 shown. Adopting the split insulated gate electrode structure can effectively reduce the gate-drain capacitance, thereby improving the dynamic performance of the device; at the same time, a new electric field peak is introduced at the interface between the gate electrode 91 and the split gate electrode 92, thereby improving the electric field distribution in the drift region and improving Device withstand voltage. In addition, the potential of the split gate electrode 92 may be positive potential, negative potential, or zero potential.

Embodiment 4

[0037]Compared with Embodiment 1, the current blocking layer 4 of the device of this example is composed of multiple P-type doped blocking layers parallel to each other in the vertical direction and having the same size, and other structures are the same as in Embodiment 1, such as Figure 6 shown. The introduction of a multi-layer P-type doped barrier layer can effectively improve the electric field distribution of the buffer layer, increase the average electric field intensity, and improve the withstand voltage of the device; in addition, due to the depletion effect of the P-type doped barrier layer on the buffer layer, it can be Increase the doping concentration of the buffer layer to a certain extent, thereby reducing the on-resistance of the device and improving the forward current output capability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com