A trench gate charge storage type insulated gate bipolar transistor and its manufacturing method

A bipolar transistor and charge storage technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of reduced switching speed, reduced device breakdown voltage, and affecting device switching loss compromise characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

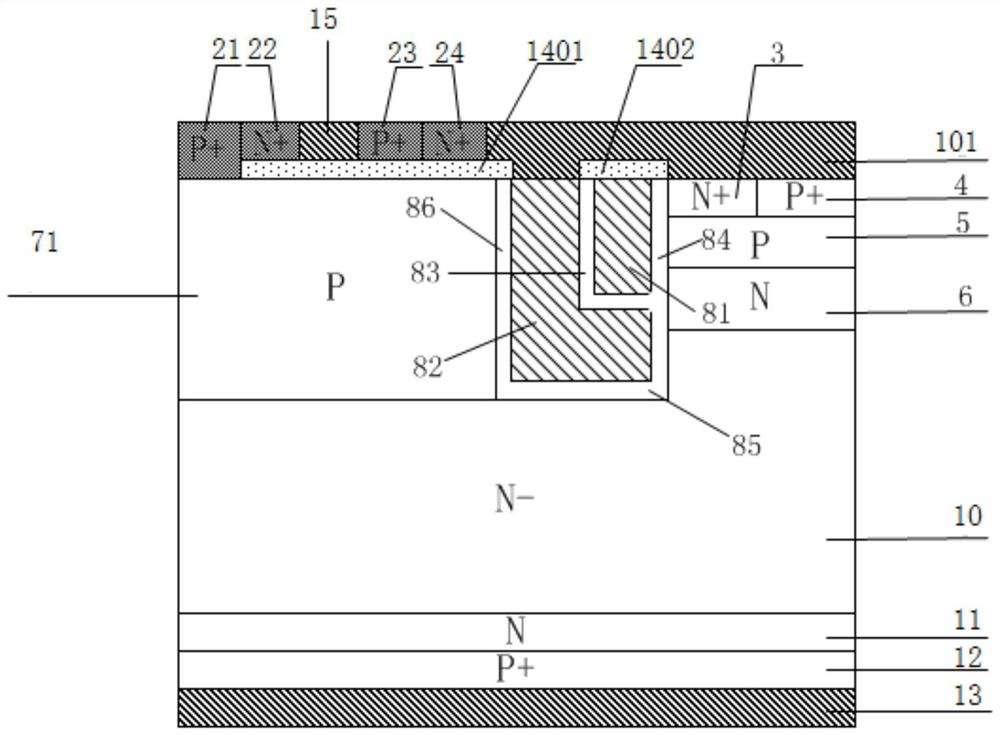

[0078] This example proposes as figure 2 A trench gate charge storage type insulated gate bipolar transistor is shown, and its cell structure includes: a P-type collector region 12, a collector metal 13 located on the back of the P-type collector region 12, a collector metal 13 located on the back of the P-type collector region The N-type electric field stop layer 11 on the front side of the region 12 and the N-type drift region 10 above the N-type electric field stop layer 11; the N-type drift region 10 has an N+ emitter region 3, a P+ emitter region 4, a P-type base region 5, and an N-type drift region 10. type charge storage layer 6, P-type body region 71 and trench gate structure; the trench gate structure partially penetrates the N-type drift region 10 along the vertical direction of the device; the P-type body region 71 is located on one side of the trench gate structure, and the P-type The base region 5 is located on the other side of the trench gate structure, and the...

Embodiment 2

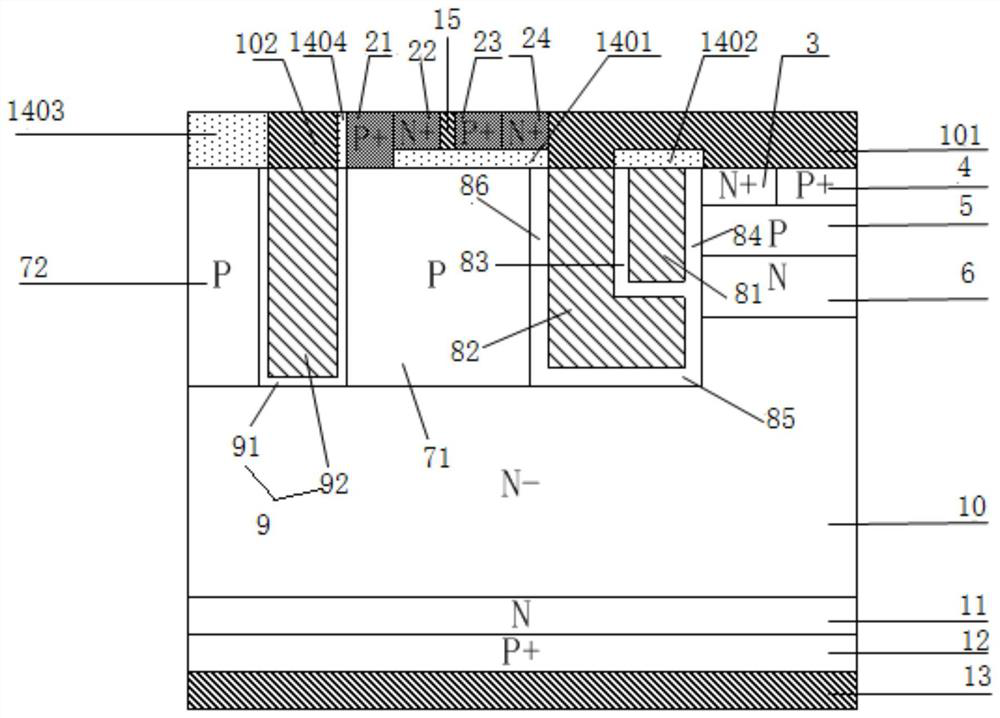

[0080] This implementation proposes as image 3A trench gate charge storage type insulated gate bipolar transistor is shown, with a P-type collector region 12, a collector metal 13 located on the back of the P-type collector region 12, and an N-type electrode located on the front side of the P-type collector region 12. The electric field stop layer 11 and the N-type drift region 10 located above the N-type electric field stop layer 11; the N-type drift region 10 has an N+ emitter region 3, a P+ emitter region 4, a P-type base region 5, an N-type charge storage layer 6, The P-type body region 71 and the trench gate structure; the trench gate structure partially penetrates the N-type drift region 10 along the vertical direction; the P-type body region 71 is located on one side of the trench gate structure, and the P-type base region 5 is located at the trench gate The other side of the structure, and the junction depth of the P-type body region 71 is greater than the junction de...

Embodiment 3

[0083] This example proposes a Figure 4 In the shown trench gate charge storage type insulated gate bipolar transistor, in this embodiment, the thickness of the split electrode dielectric layer (that is, the first split electrode dielectric layer 85 and the second split electrode dielectric layer 86) is greater than that of the gate dielectric layer (that is, the thicknesses of the first gate dielectric layer 83 and the second gate dielectric layer 84 ), the rest are the same as those in Embodiment 2.

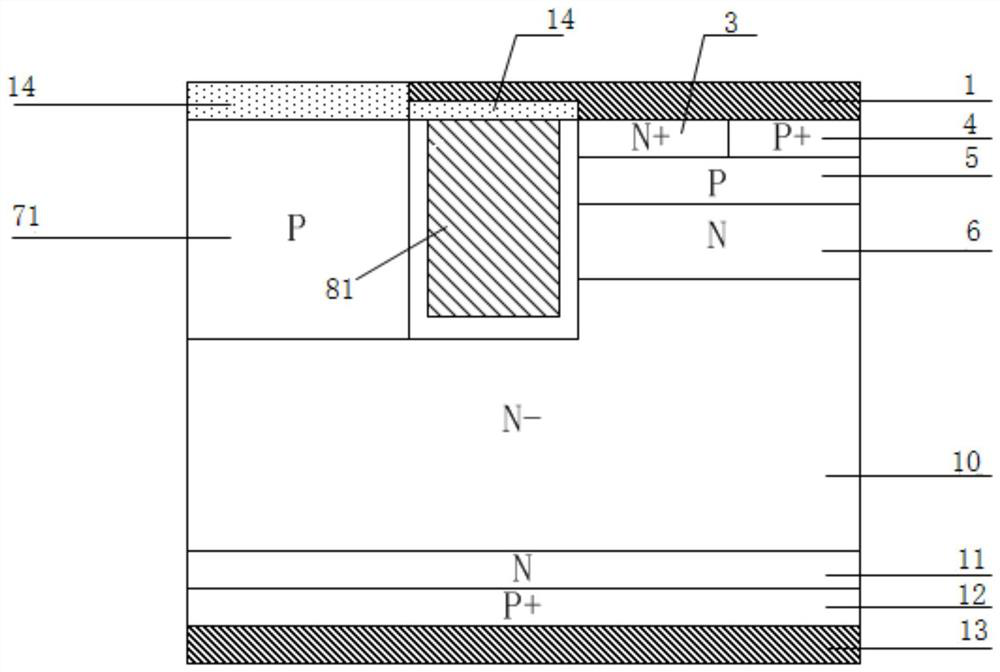

[0084] Such as figure 1 Shown is the structure of a traditional trench gate charge storage type insulated gate bipolar transistor. The gate oxide layer is formed in the trench by one thermal oxidation. In order to ensure a certain threshold voltage, the thickness of the entire gate oxide layer is small. The MOS capacitance is inversely proportional to the thickness of the gate oxide layer. Therefore, the thin gate oxide layer thickness in the traditional CSTBT structure great...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com