A resurf HEMT device with n-type floating buried layer

An N-type, floating technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of limiting gate voltage swing, and achieve the effect of increasing breakdown voltage, improving electric field concentration effect, and uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

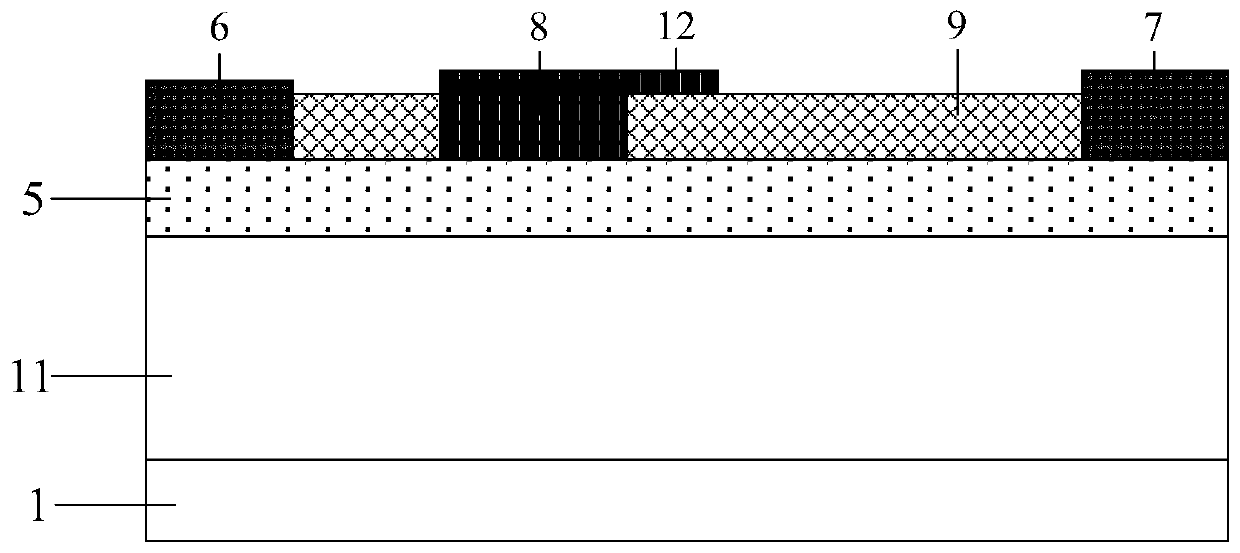

[0030] Figure 4 A RESURF HEMT device with an N-type floating buried layer is shown. This example device includes:

[0031] Substrate 1, buffer layer 2 located on top of substrate 1, N-type channel layer 4 located on top of buffer layer 2, barrier layer 5 located on top of channel layer 4, and passivation layer 9 located on top of barrier layer 5 ; Both ends of the upper surface of the barrier layer 5 are respectively provided with a source electrode 6 and a drain electrode 7, and a gate electrode 8 is provided between the source electrode 6 and the drain electrode 7; the source electrode 6 and the drain electrode 7 are ohmic contact . It is characterized in that the buffer layer 2 is P-type doped, the P-type buffer layer 2 has an N-type floating buried layer 3, and the N-type floating buried layer 3 is spaced from the channel layer 4; the The N-type floating buried layer 3 horizontally extends from below the drain electrode 7 to between the gate electrode 8 and the drain e...

Embodiment 2

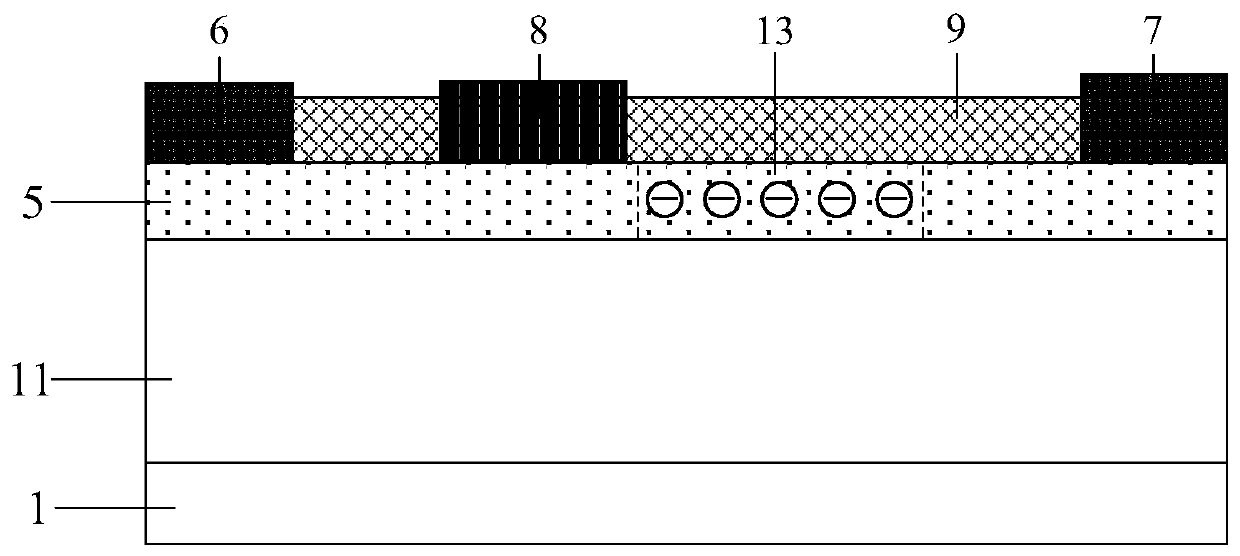

[0034] Compared with Example 1, the N-type floating buried layer of the device in this example is a multi-layer structure, and other structures are the same as those in Example 1, such as Figure 5 shown. Since the multi-layer N-type floating buried layer and the P-type buffer layer form multiple PN junctions, the vertical depletion width of the device can be further expanded, so as to further improve the electric field concentration effect at the drain electrode terminal and optimize the surface electric field of the device to increase the breakdown voltage.

Embodiment 3

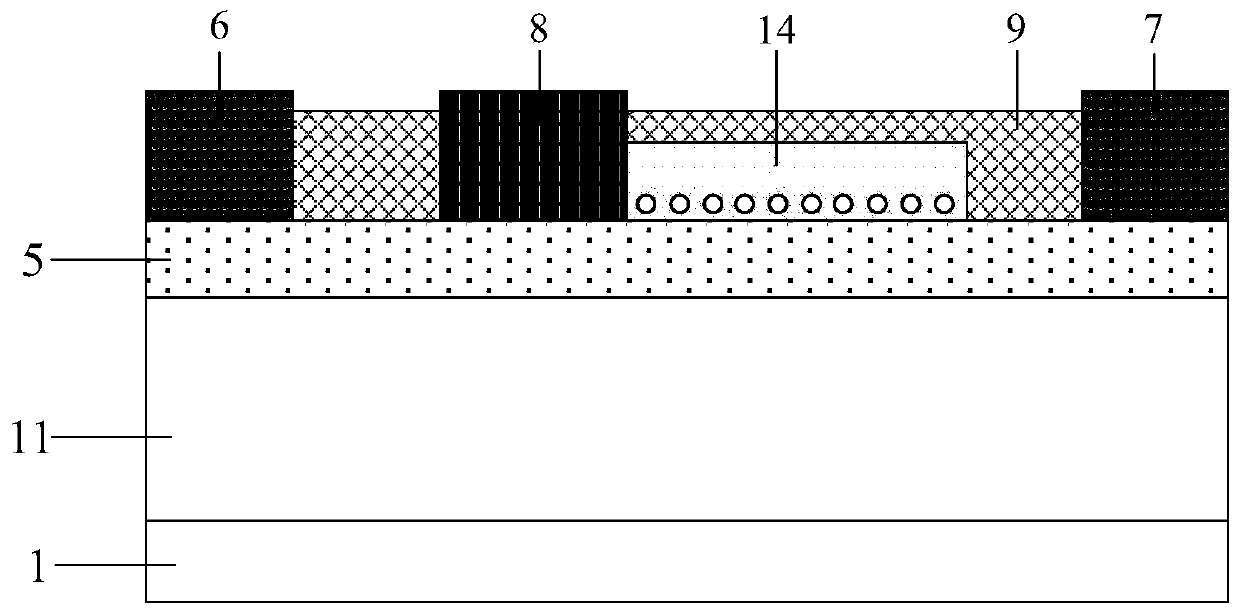

[0036] Compared with Embodiment 1, the N-type floating buried layer of the device in this example is doped laterally, and the other structures are the same as those of Embodiment 1, such as Image 6 shown. Compared with Example 1, the use of lateral segmented doping can further optimize the electric field distribution in the body, increase the average electric field strength, and further improve the off-state breakdown voltage of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com