Preparation method of high-immune plasma protein powder

A technology for plasma protein powder and plasma is applied in the field of preparation of high-immunity plasma protein powder, which can solve the problems of reducing the biological value of products, difficult to kill pathogenic microorganisms, and high energy consumption, so as to enhance product functionality and ensure biological safety. the effect of improving protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

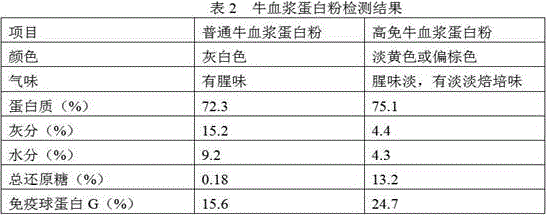

Embodiment 1

[0023] Raw material selection: fresh pig plasma from healthy pigs;

[0024] A. Take the freshly separated porcine plasma, pass the porcine plasma through a 150-mesh filter bag, and pump it into an inorganic membrane filtration system with a pore size of 0.22 μm, then pump the filtrate into an organic membrane concentration system with a molecular weight cut-off of 10000D, and circulate concentration, desalination and dehydration. Obtain a concentrated plasma solution with a solid content of 18%;

[0025] B. Pump the concentrated plasma liquid into a storage tank equipped with a stirrer, add reducing sugar according to the mass percentage of 2.0% of the total plasma, the added reducing sugar is maltodextrin sugar and glucose, and the mass ratio is 3:1, and then Stir and dissolve at 40°C and 180 rpm for 25 minutes to obtain sugar-added plasma;

[0026] C. Pump the sugar-added plasma liquid into the homogenizer, and under the condition of pressure 20MPa, homogenize under high pr...

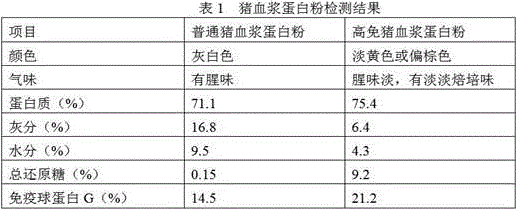

Embodiment 2

[0046] Raw material selection: fresh blood plasma from healthy cattle

[0047] A. Take the freshly separated bovine plasma, pass the bovine plasma through a 150-mesh filter bag, and pump it into an inorganic membrane filtration system with a pore size of 0.22 μm, and then pump the filtrate into an organic membrane concentration system with a molecular weight cut-off of 20,000D for circular concentration, desalination and dehydration. Obtain a concentrated plasma solution with a solid content of 20%;

[0048] B. Pump the concentrated plasma liquid into a storage tank equipped with a stirrer, and add reducing sugar according to the mass percentage of 3.0% of the total plasma. The added reducing sugar is maltodextrin, glucose and fructose, and the mass ratio is 2:1 : 1, then stirred and dissolved at 45°C and 200 rpm for 30 minutes to obtain sugar-added plasma;

[0049] C. Pump the sugar-added plasma liquid into the homogenizer, under the condition of pressure 30MPa, high-pressur...

Embodiment 3

[0057] Raw material selection: Fresh blood plasma from healthy chicken

[0058] A. Take the freshly separated chicken plasma, pass the chicken plasma through a 150-mesh filter bag, pump it into an inorganic membrane filtration system with a pore size of 0.22 μm, and then pump the filtrate into an organic membrane concentration system with a molecular weight cut-off of 10000D, and circulate concentration for desalination and dehydration. Obtain a concentrated plasma solution with a solid content of 16%;

[0059] B. Pump the concentrated plasma liquid into a storage tank equipped with a stirrer, add reducing sugar according to the mass percentage of 1.0% of the total plasma, the added reducing sugar is maltodextrin, glucose and maltose, and its mass ratio is 8:1 : 1, then stirred and dissolved at 30°C and 120 rpm for 15 minutes to obtain sugar-added plasma;

[0060] C. Pump the sugar-added plasma liquid into the homogenizer, and under the condition of pressure 10MPa, homogenize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com