Preparation method of dendrobium polysaccharide beverage and beverage adopting same

A Dendrobium polysaccharide and beverage technology, applied in the field of Dendrobium polysaccharide beverage and its preparation, can solve the problems of low extraction rate of active functional components, waste of raw materials of Dendrobium officinale, increased processing costs, etc., and achieve good health effects, rich content, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

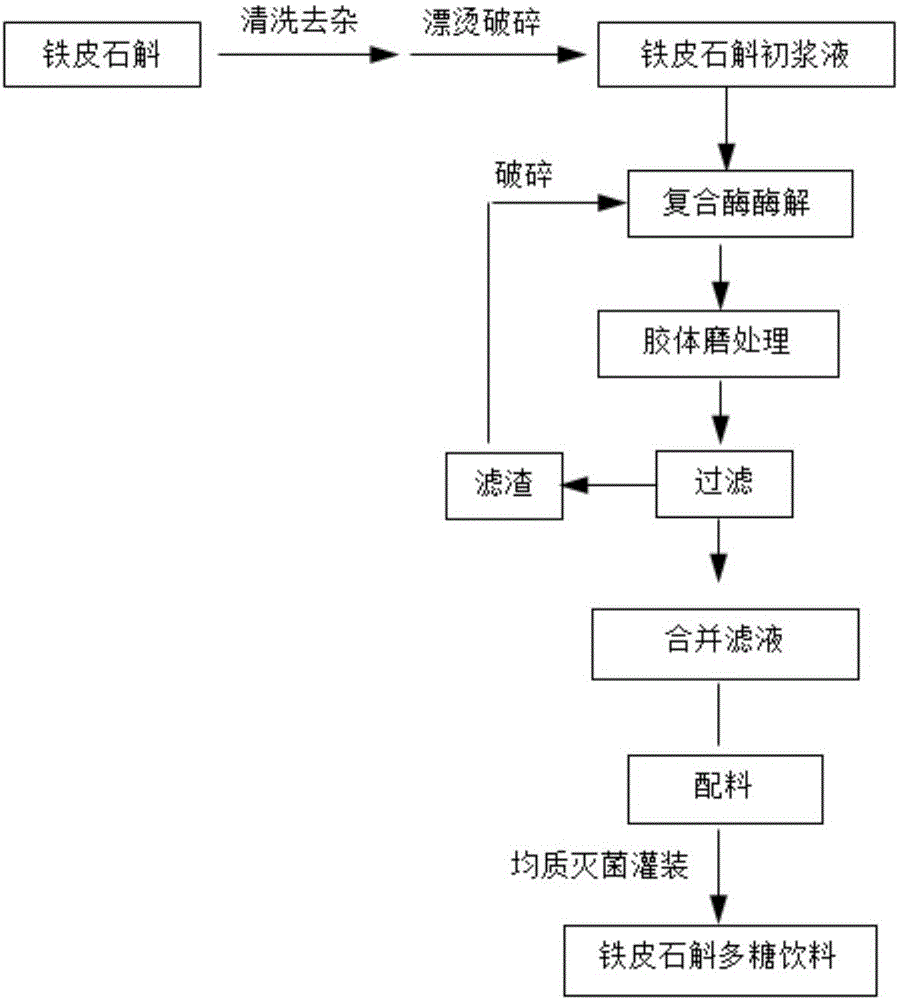

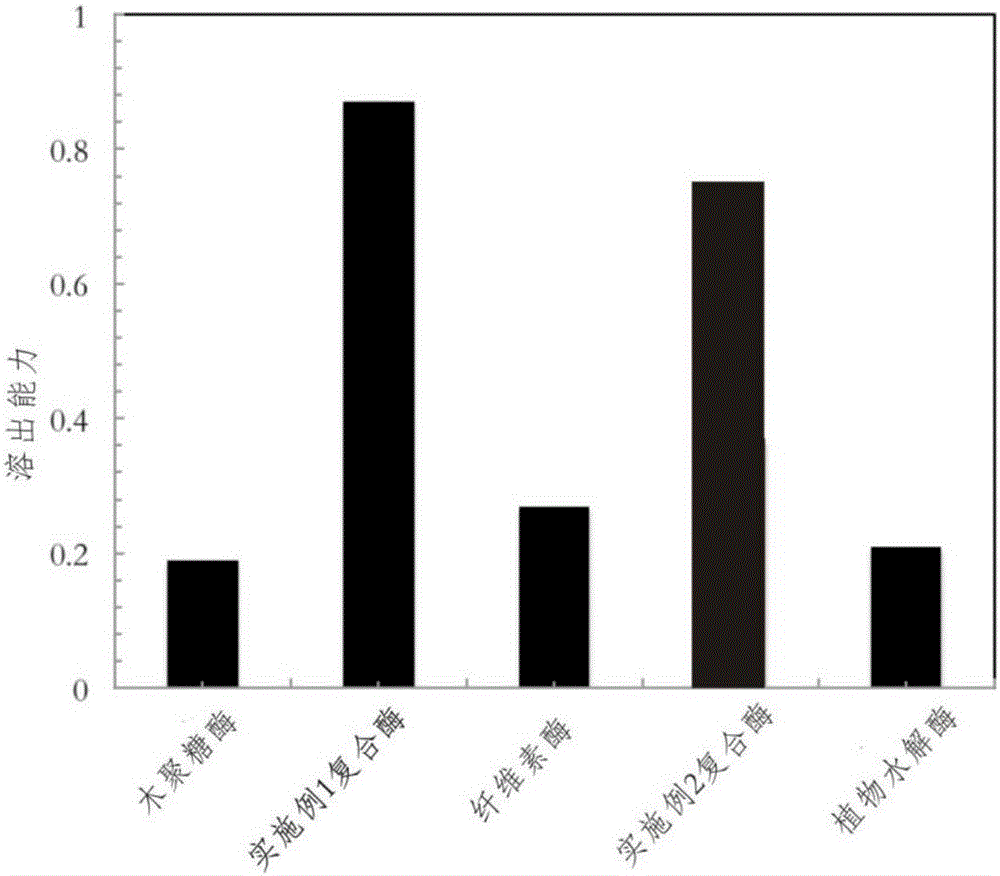

[0029] see figure 1 and figure 2 , with the fresh strips of Dendrobium candidum as raw material, it is cleaned, removed impurities, dried, blanched with 70 ℃ 100mg / L zinc acetate aqueous solution with a pH of 7 for 5min, after cooling with tap water, add demineralized water with 3 times the quality of the material to be treated Coarsely crushed in a pulverizer. After the crushed Dendrobium was beaten and kept at 60°C for 60 minutes, it was filtered with a plate and frame filter, and the obtained filtrate and filter residue were collected. Select the compound enzyme cellulase Cellic Ctec3: xylanase Pentopan Mono BG: pectinase Pectines BE XXL: compound protease Protamex=3:2:1:1, the addition amount is 0.5%, after beating the filter residue obtained by filtration, in Hydrolyze for 60 minutes at 60°C and adjust the pH to 5.5 with phytic acid, then refine the pulp in a colloid mill for 5 minutes at 10 MPa, filter, and collect the filtrate and filter residue. This operation was ...

Embodiment 2

[0031] Take the dry branch of Dendrobium candidum as raw material, wash it, remove impurities, dry it, and blanch it with 100mg / L ascorbic acid aqueous solution at 70°C with a pH of 6 for 3 minutes. Medium coarse broken. The crushed dendrobium was beaten and kept at 65°C for 50 minutes, then filtered with a plate and frame filter, and the obtained filtrate and filter residue were collected. Select compound enzyme cellulase HY-2541: xylanase Shearzyme 500L: pectinase Pectines Ultra Color: compound protease Protamex=2:2:1:1, the addition amount is 2%, after beating the filter residue obtained by filtration, in Hydrolyze for 50 minutes at 50°C and adjust the pH to 5 with phytic acid, then refine the pulp in a colloid mill at 5 MPa for 5 minutes, filter, and collect the filtrate and filter residue. This operation was repeated three times, and the yield of dendrobium polysaccharide was 19.2%, and the yield of dendrobine was 0.37%. Merge the filtrates of all the above-mentioned fi...

Embodiment 3

[0033] Take the dry branch of Dendrobium candidum as raw material, clean it, remove impurities, dry it, and blanch it with 150mg / L ascorbic acid aqueous solution with a pH of 6.5 at 75°C for 3 minutes, and after cooling with tap water, add demineralized water of 2 times the weight of the material to be treated in a pulverizer Medium coarse broken. After the crushed Dendrobium was beaten and kept at 80°C for 90 minutes, it was filtered with a plate and frame filter, and the obtained filtrate and filter residue were collected. Select compound enzyme cellulase HY-2541: xylanase Pentopan Mono BG: pectinase Pectines XXL: compound protease Protamex=1:1:1:1, the addition amount is 3%, after beating the filter residue obtained by filtration, in Under the conditions of 55°C and citric acid to adjust the pH to 5, hydrolyze for 60 minutes, then refine the slurry in a colloid mill at 5 MPa for 5 minutes, filter, and collect the filtrate and filter residue. This operation was repeated twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com