Martensite stainless-steel composite steel plate and production method thereof

A technology of martensitic stainless steel and clad steel plate, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of martensitic stainless steel and carbon steel compounding difficulties, and improve the comprehensive utilization rate of materials , cost reduction, excellent strength and toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

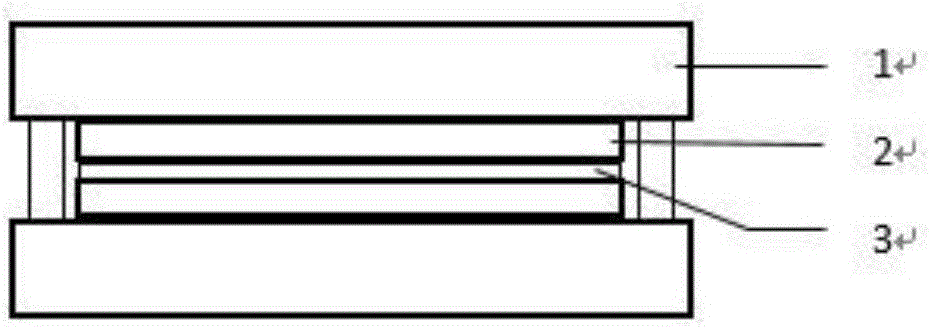

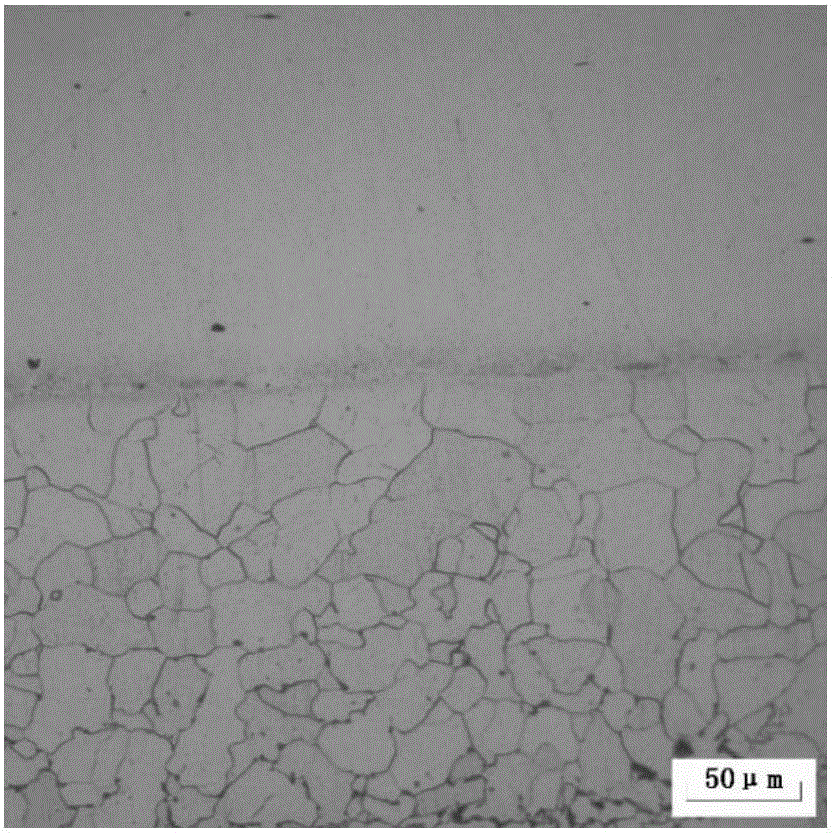

[0017] The chemical composition weight percentage content of the steel base material A516Gr70 carbon steel 1 is: C: 0.21%, Si: 0.25%, Mn: 1.17%, P: 0.015%, S: 0.0036%, the balance is Fe and unavoidable impurities element. Clad 410S martensitic stainless steel 2 chemical composition weight percent content is: C: 0.040%, Si: 0.53%, Mn: 0.26%, P: 0.016%, S: 0.003%, Cr: 12.9%, Ni: 0.12%, The balance is Fe and unavoidable impurity elements. .

[0018] The steel plate specifications are: (18+4)×2100×L mm (thickness×width×length), in which the thickness of the base layer A516Gr70 carbon steel 1 is 18mm, and the thickness of the cladding 410S martensitic stainless steel 2 is 4mm.

[0019] The production process includes: billet formation, heating, rolling, and heat treatment, specifically:

[0020] 1. The thickness of the base A516Gr70 carbon steel billet 1 is 126mm, and the thickness of the cladding 410S martensitic stainless steel billet 2 is 29mm. The surface of the billet is po...

Embodiment 2

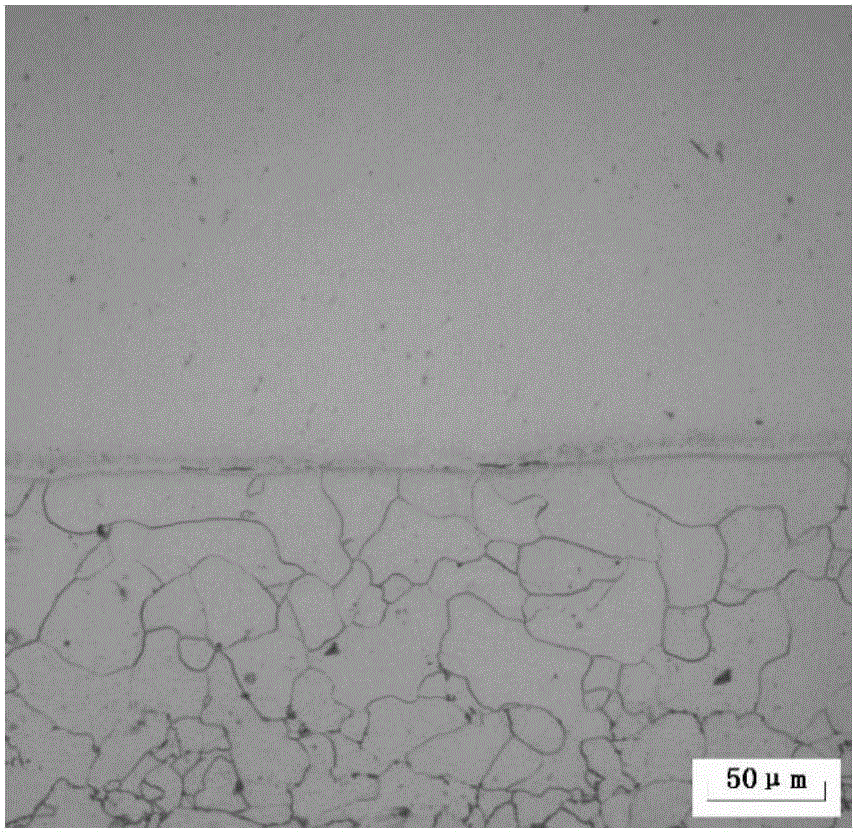

[0027] The chemical composition weight percentage content of the steel base material A516Gr70 carbon steel 1 is: C: 0.2%, Si: 0.25%, Mn: 1.19%, P: 0.016%, S: 0.0035%, the balance is Fe and unavoidable impurities element. Clad 410S martensitic stainless steel 2 chemical composition weight percent content is: C: 0.043%, Si: 0.68%, Mn: 0.20%, Cr: 13.2%, Ni: 0.16%, P: 0.02%, S: 0.002%, The balance is Fe and unavoidable impurity elements.

[0028] The steel plate specification is: (16+4)×2000×L mm (thickness×width×length), in which the thickness of the base layer is 16mm, and the thickness of the stainless steel is 4mm.

[0029] The production process includes billet assembly, heating, rolling, and heat treatment, specifically:

[0030] 1. The thickness of the base A516Gr70 carbon steel billet 1 is 112mm, and the thickness of the cladding 410S martensitic stainless steel billet 2 is 29mm. The surface of the billet is cleaned to ensure the cleanliness of the composite surface; Ad...

Embodiment 3

[0037] The chemical composition weight percentage content of the steel base material A516Gr70 carbon steel 1 is: C: 0.22%, Si: 0.23%, Mn: 1.18%, P: 0.015%, S: 0.0032%, the balance is Fe and unavoidable impurities element. Clad 410S martensitic stainless steel 2 chemical composition weight percent content is: C: 0.040%, Si: 0.69%, Mn: 0.20%, Cr: 13.3%, Ni: 0.16%, P: 0.016%, S: 0.0014%, The balance is Fe and unavoidable impurity elements.

[0038] The steel plate specification is: (20+4)×2650×L mm (thickness×width×length), in which the thickness of the base layer A516Gr70 carbon steel 1 is 20mm, and the thickness of the cladding 410S martensitic stainless steel 2 is 4mm.

[0039] The production process includes billet assembly, heating, rolling, and heat treatment, specifically:

[0040]1. The thickness of the base A516Gr70 carbon steel billet 1 is 140mm, and the thickness of the cladding 410S martensitic stainless steel billet 2 is 29mm. The surface of the billet is cleaned t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com