A kind of preparation method of cyclooxygenase-2 inhibitor parecoxib

A technology of parecoxib and cyclooxygenase, which is applied in the field of drug synthesis, can solve problems such as the safety impact of waste discharge operators, difficulty in reaction treatment, and corrosiveness of compounds, and achieve reduced reaction time, simple reaction steps, and high yield. rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

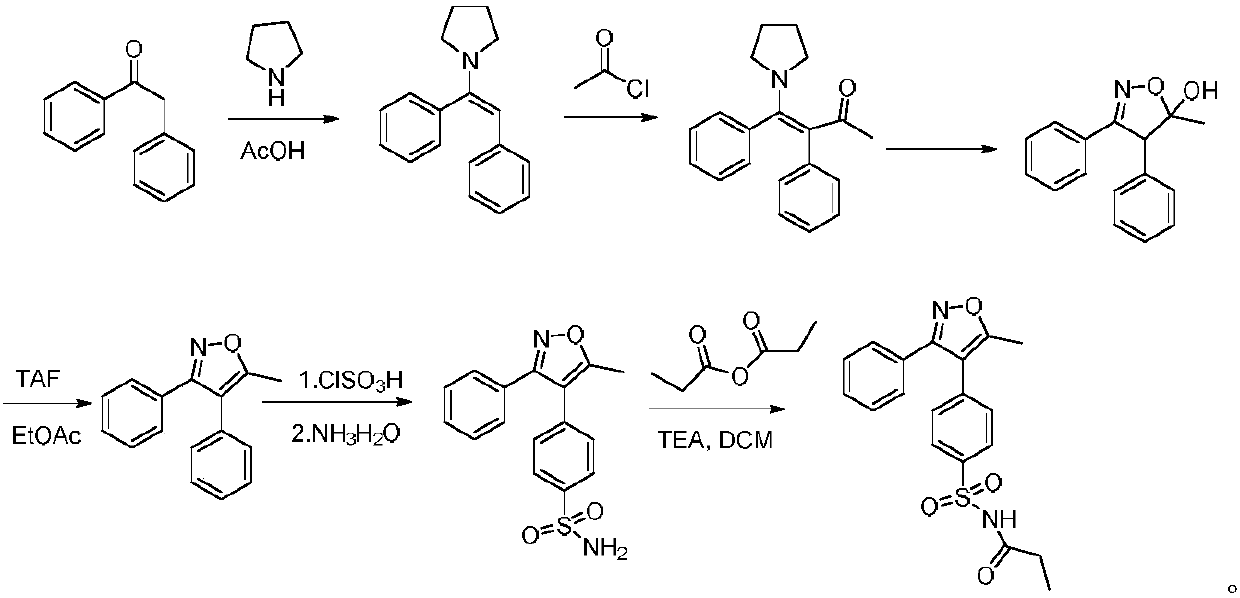

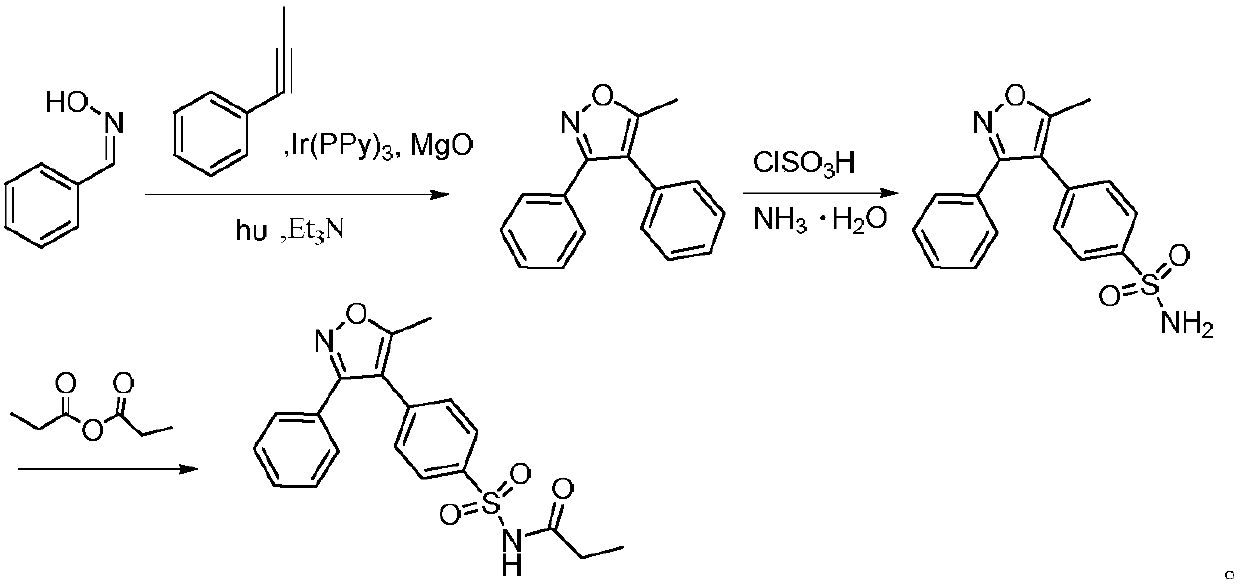

Method used

Image

Examples

Embodiment 1

[0025] Preparation of 5-methyl-3,4-diphenylisoxazole

[0026] Mix 12.1 g (100 mmol) of benzaldoxime with 12.8 g (110 mmol) of 1-phenylpropyne, 3.9 g (6 mmol) of tris(2-phenylpyridine) iridium (III), 8.1 g (80 mmol) of triethylamine and Magnesium oxide 0.4g (10mmol) was added to a flask containing 30ml THF, and the light reaction was carried out at 25°C for 35min. The light was emitted by a blue light-emitting diode with a wavelength of 460nm. The reaction solution was concentrated, washed with water, recrystallized from ethanol, and dried to obtain 23.0 g of 5-methyl-3,4-diphenylisoxazole with a yield of 97.8% and a purity of 99.64%.

Embodiment 2

[0028] Preparation of 5-methyl-3,4-diphenylisoxazole

[0029] Mix 12.1 g (100 mmol) of benzaldoxime with 13.9 g (120 mmol) of 1-phenylpropyne, 5.2 g (8 mmol) of tris(2-phenylpyridine) iridium (III), 7.1 g (70 mmol) of triethylamine and Magnesium oxide 0.8g (20mmol) was added to a flask containing 30ml THF, and the light reaction was carried out at 25°C for 30min. The light was emitted by a blue light-emitting diode with a wavelength of 460nm. The reaction solution was concentrated, washed with water, recrystallized from ethanol, and dried to obtain 23.2 g of 5-methyl-3,4-diphenylisoxazole with a yield of 98.5% and a purity of 99.47%.

Embodiment 3

[0031] Preparation of 5-methyl-3,4-diphenylisoxazole

[0032] Mix 12.1 g (100 mmol) of benzaldoxime with 15.1 g (130 mmol) of 1-phenylpropyne, 3.2 g (5 mmol) of tris(2-phenylpyridine) iridium (III), 6 g (60 mmol) of triethylamine and Magnesium 0.6g (15mmol) was added into a flask filled with 30ml THF, and the light reaction was carried out at 30°C for 40min. The light was emitted by a blue light-emitting diode, and the light wavelength was 470nm. The reaction solution was concentrated, washed with water, recrystallized from ethanol, and dried to obtain 22.9 g of 5-methyl-3,4-diphenylisoxazole with a yield of 97.2% and a purity of 99.36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com