Method for increasing polyolefin grafting efficiency

A technology of grafting efficiency and polyolefin, which is applied in the field of polyolefin modification, can solve the problems of low efficiency and low grafting efficiency of graft copolymers, so as to reduce crosslinking or degradation, improve initiation efficiency and polyolefin grafting Efficiency, the effect of preventing excessive local free radical concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

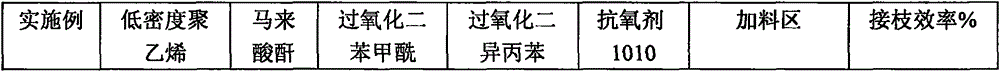

[0033] Embodiment 1: comparative example

[0034] Take by weighing 93.9 parts of low-density polyethylene (parts by weight, the same below), 5.0 parts of maleic anhydride, 0.1 part of initiator 1 dibenzoyl peroxide, and 1.0 part of antioxidant 1010, and dissolve maleic anhydride in 5.0 parts without In water ethanol, dissolve dibenzoyl peroxide in 5.0 parts of absolute ethanol, mix low-density polyethylene, dibenzoyl peroxide solution, maleic anhydride solution, and antioxidant 1010 in a high-speed mixer , put the above mixture into the hopper of the extruder, the temperature of each zone of the extruder is between 140°C and 190°C, the speed of the main screw is 70 rpm, the speed of the feeding screw is 60 rpm, and the extruded product is drawn, cooled, drying and pelletizing to obtain polar monomer graft modified polyolefin particles.

Embodiment 2

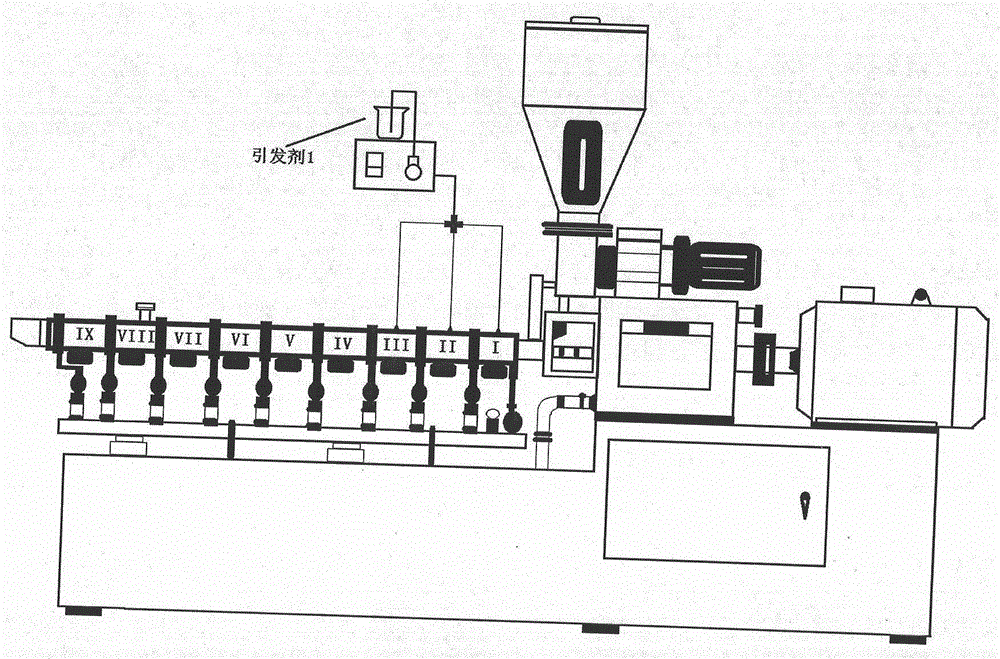

[0036] Take by weighing 93.9 parts of low-density polyethylene (parts by weight, the same below), 5.0 parts of maleic anhydride, 0.1 part of initiator 1 dibenzoyl peroxide, and 1.0 part of antioxidant 1010, and dissolve maleic anhydride in 5.0 parts without In water ethanol, dissolve dibenzoyl peroxide in 5.0 parts of absolute ethanol, mix low-density polyethylene, maleic anhydride solution, and antioxidant 1010 in a high-speed mixer, and add the above mixture to the extruder In the hopper, the temperature of each zone of the extruder is between 140°C and 190°C, the speed of the main screw is 70 rpm, and the speed of the feeding screw is 60 rpm, and the dibenzoyl peroxide solution is pumped into the extruder I and Zone II, the pumping speeds are 1 part / minute and 0.8 part / minute respectively, and the extruded product is drawn, cooled, dried and pelletized to obtain polar monomer grafted modified polyolefin particles.

Embodiment 3

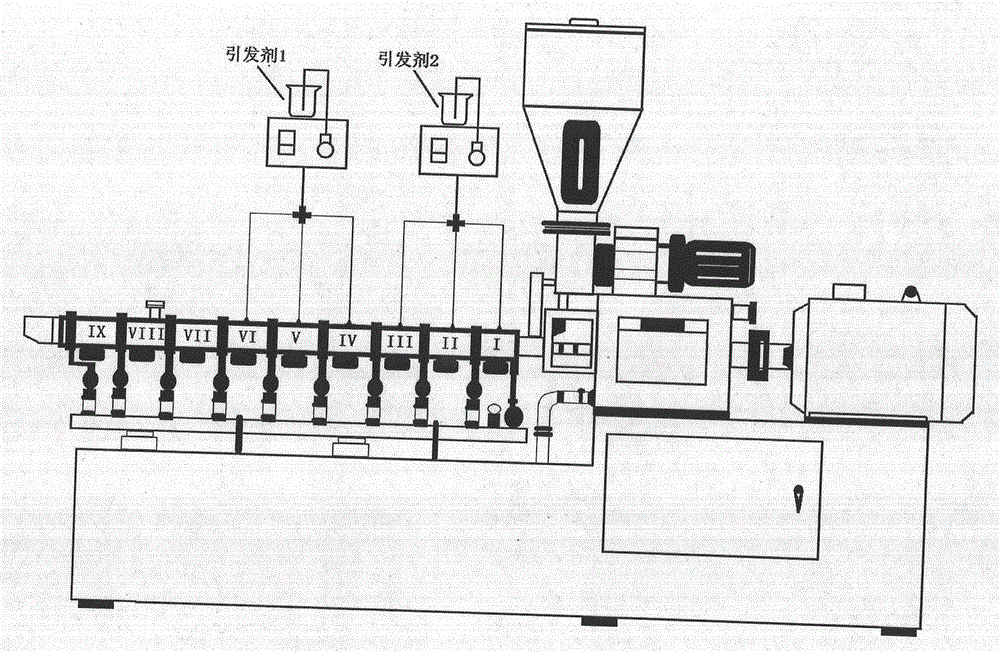

[0038] Take by weighing 93.9 parts of low-density polyethylene (parts by weight, the same below), 5.0 parts of maleic anhydride, 0.1 part of initiator 1 dibenzoyl peroxide, and 1.0 part of antioxidant 1010, and dissolve maleic anhydride in 5.0 parts without In water ethanol, dissolve dibenzoyl peroxide in 5.0 parts of absolute ethanol, mix low-density polyethylene, maleic anhydride solution, and antioxidant 1010 in a high-speed mixer, and add the above mixture to the extruder In the hopper, the temperature of each zone of the extruder is between 140°C and 190°C, the speed of the main screw is 70 rpm, and the speed of the feeding screw is 60 rpm, and the dibenzoyl peroxide solution is pumped into the extruder I , II, and III areas, the pumping speed is 1 part / min, 0.8 part / min, 0.6 part / min respectively, and the extrudate is drawn, cooled, dried, and pelletized to obtain a polar monomer graft-modified polymer Olefin pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com