A kind of fluorocarbon ink and preparation method and a kind of fluorocarbon ink transfer film

A fluorocarbon and ink technology, applied in the directions of reproduction/marking method, ink, printing, etc., can solve the problems of uneven anti-corrosion effect, corrosion and discoloration of plates, waste of artificial energy, etc., to improve the effect of pigment dispersion and arrangement, and enhance solvent resistance. Aggressive, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

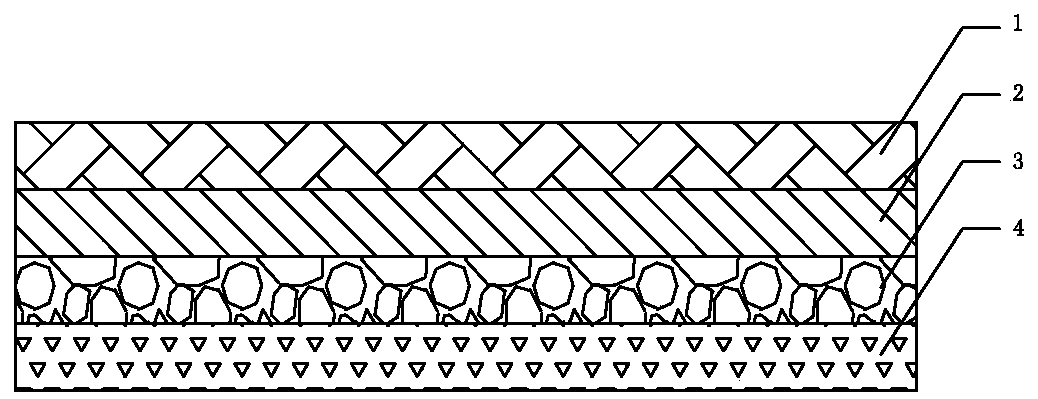

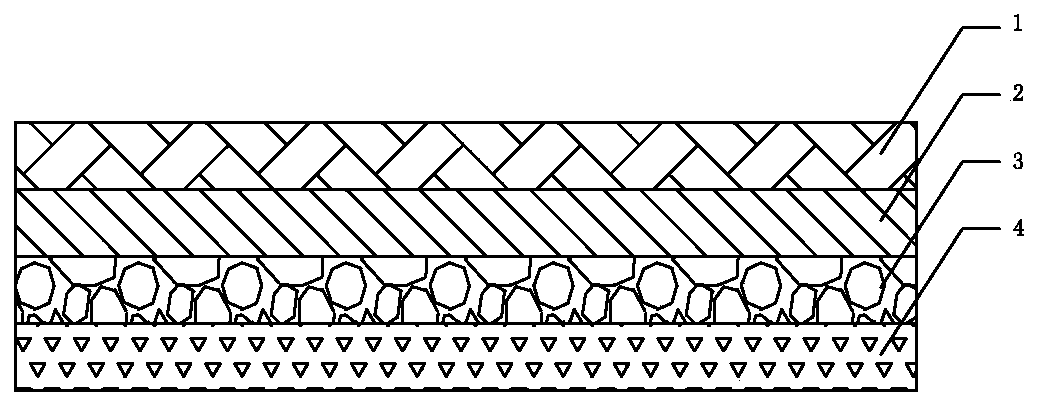

[0043] A fluorocarbon ink transfer film is composed of a base film layer 1, an attached release layer 2, a fluorocarbon ink pattern layer 3, and an adhesive layer 4 that are stacked in sequence, and the fluorocarbon ink pattern layer 3 passes through the attached The release layer 2 is formed by printing fluorocarbon ink.

[0044] Described fluorocarbon ink comprises the raw material of following parts by weight:

[0045] Acrylic resin 19 parts

[0046] Fluorocarbon resin 29 parts

[0047] CAB resin emulsion 5.5 parts

[0048] Curing agent 1.5 parts

[0049] Pigment 17.5 parts

[0050] Dispersant 0.75 parts

[0051] Matte powder 0.75 parts

[0052]26 parts of organic solvents.

[0053] Wherein, the acrylic resin is Rohm and Haas B-44, the fluorocarbon resin is Arkema 460, the CAB resin content of the CAB resin emulsion is 15-25wt%, and the CAB resin is Eastman CAB- 381-0.5, the curing agent is 3175 of Bayer, the pigment is titanium dioxide, the dispersant is Lubrizol 8...

Embodiment 2

[0055] A fluorocarbon ink transfer film is composed of a base film layer 1, an attached release layer 2, a fluorocarbon ink pattern layer 3, and an adhesive layer 4 that are stacked in sequence, and the fluorocarbon ink pattern layer 3 passes through the attached The release layer 2 is formed by printing fluorocarbon ink.

[0056] Described fluorocarbon ink comprises the raw material of following parts by weight:

[0057] 18 parts acrylic resin

[0058] Fluorocarbon resin 28 parts

[0059] CAB resin emulsion 5 parts

[0060] Curing agent 1 part

[0061] Pigment 15 parts

[0062] Dispersant 0.5 parts

[0063] Matte powder 0.5 parts

[0064] 20 parts of organic solvent.

[0065] Wherein, the acrylic resin is Rohm and Haas B-44, the fluorocarbon resin is Arkema 460, the CAB resin content of the CAB resin emulsion is 15wt%, and the acetyl group content of the CAB resin is 10wt%, The butyryl content is 40wt%, the hydroxyl content is 1wt%, the curing agent is Bayer's 3175, t...

Embodiment 3

[0067] A fluorocarbon ink transfer film is composed of a base film layer 1, an attached release layer 2, a fluorocarbon ink pattern layer 3, and an adhesive layer 4 that are stacked in sequence, and the fluorocarbon ink pattern layer 3 passes through the attached The release layer 2 is formed by printing fluorocarbon ink.

[0068] Described fluorocarbon ink comprises the raw material of following parts by weight:

[0069] 20 parts acrylic resin

[0070] Fluorocarbon resin 30 parts

[0071] CAB resin emulsion 6 parts

[0072] Hardener 2 parts

[0073] Pigment 20 parts

[0074] 1 part dispersant

[0075] matte powder 1 part

[0076] 32 parts of organic solvents.

[0077] Wherein, the acrylic resin is Rohm and Haas B-44, the fluorocarbon resin is Arkema 460, the CAB resin content of the CAB resin emulsion is 25wt%, and the acetyl group content of the CAB resin is 15wt%, The butyryl content is 35wt%, the hydroxyl content is 2wt%, the curing agent is Bayer's 3175, the pigme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com