Method for preparing lysimachia foenum-graecum herb composite perfume through synthesis technology and application thereof

A technology of Guangling incense and spices, applied in the fields of application, tobacco, food science, etc., to achieve the effect of large industrial application prospects, simple process conditions, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

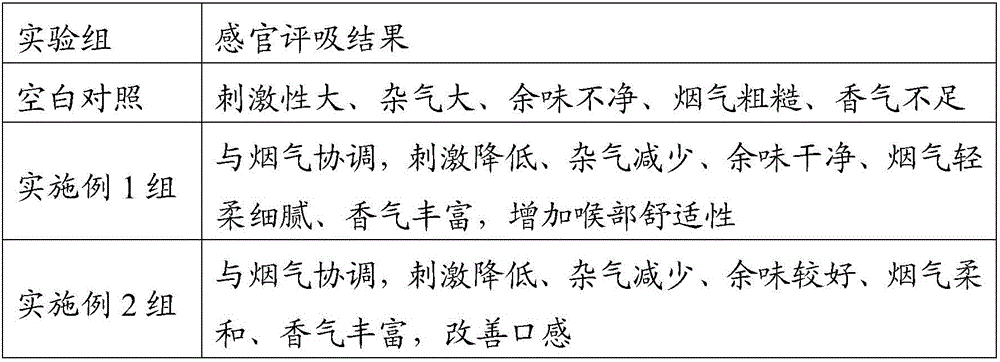

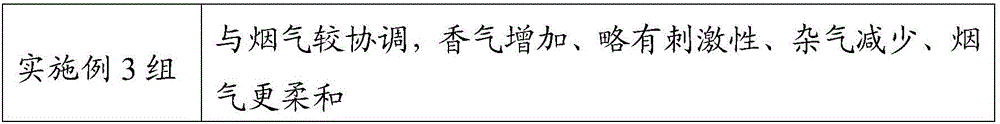

Examples

Embodiment 1

[0023] (1) The slag water after extracting the volatile oil from Guanglingxiang, adjust the pH to 4.5 with acetic acid, balance at 45°C for half an hour, add a compound enzyme with a mass ratio of 0.1% of slag to water, mix well, keep stirring, and warm at 40°C 12 hours of incubation;

[0024] The slag water after extracting the volatile oil of Guanglingxiang, the mass ratio of Guanglingxiang dry grass: water is 1:10, and the residue water remaining after steam distillation.

[0025] The compound enzyme is food grade, β-glucosidase (enzyme activity 100u / g), cellulase and protease (enzyme activity both are 20,000u / g), and the mass ratio is 1:0.1:0.1.

[0026] (2) Adding 10% ethanol to the total volume ratio, mixing evenly, heating and refluxing for extraction for 3 hours, suction filtration, and concentrating the filtrate to a relative density of 1.12 to obtain Guanglingxiang spice a;

[0027] The ethanol is food grade 95%.

[0028] (3) For the filter residue in the above ste...

Embodiment 2

[0033] (1) The slag water after extracting the volatile oil from Guanglingxiang, adjust the pH to 5.2 with acetic acid, balance at 50°C for half an hour, add a compound enzyme with a mass ratio of 0.2% of slag to water, mix well, keep stirring, and warm at 45°C 28 hours of incubation;

[0034] The slag water after extracting the volatile oil of the radix radix radiata, the mass ratio of the radix radix hay:water is 1:20, and the slag water remaining after steam distillation.

[0035] The compound enzyme is food grade, β-glucosidase (enzyme activity: 1000u / g), cellulase and protease (both enzyme activity is 80,000u / g), and the mass ratio is 1:0.08:0.05.

[0036] (2) Add ethanol accounting for 20% of the total volume ratio, mix evenly, heat and reflux for extraction for 4 hours, filter with suction, and concentrate the filtrate to a relative density of 1.2 to obtain Guanglingxiang spice a;

[0037] The ethanol is food grade 95%.

[0038] (3) For the filter residue in the above...

Embodiment 3

[0043](1) The slag water after extracting the volatile oil from Guanglingxiang, adjust the pH to 6.0 with acetic acid, balance at 55°C for half an hour, add a compound enzyme with a mass ratio of 0.3% of slag to water, mix well, keep stirring, and warm at 50°C 45 hours of incubation;

[0044] The slag water after extracting the volatile oil of the radix radix radiata has a mass ratio of radix radix hay:water of 1:30, and the slag water remaining after steam distillation.

[0045] The compound enzyme is food grade, β-glucosidase (enzyme activity 10,000 u / g), cellulase and protease (enzyme activity 100,000 u / g), and the mass ratio is 1:0.1:0.1.

[0046] (2) Add 30% ethanol to the total volume and mix evenly, heat and reflux for extraction for 5 hours, filter with suction, and concentrate the filtrate to a relative density of 1.3 to obtain Guanglingxiang spice a;

[0047] The ethanol is food grade 95%.

[0048] (3) For the filter residue in the above step (2), add 60% ethanol s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com