Preparing method for vanadium oxide film

A technology of vanadium oxide and film layer, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problem of limited improvement of phase transition temperature or thermal hysteresis curve shape, long preparation time of vanadium oxide film layer, film Layer structure design is limited and other issues, to shorten the heating annealing time, improve annealing production efficiency, shorten the effect of cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

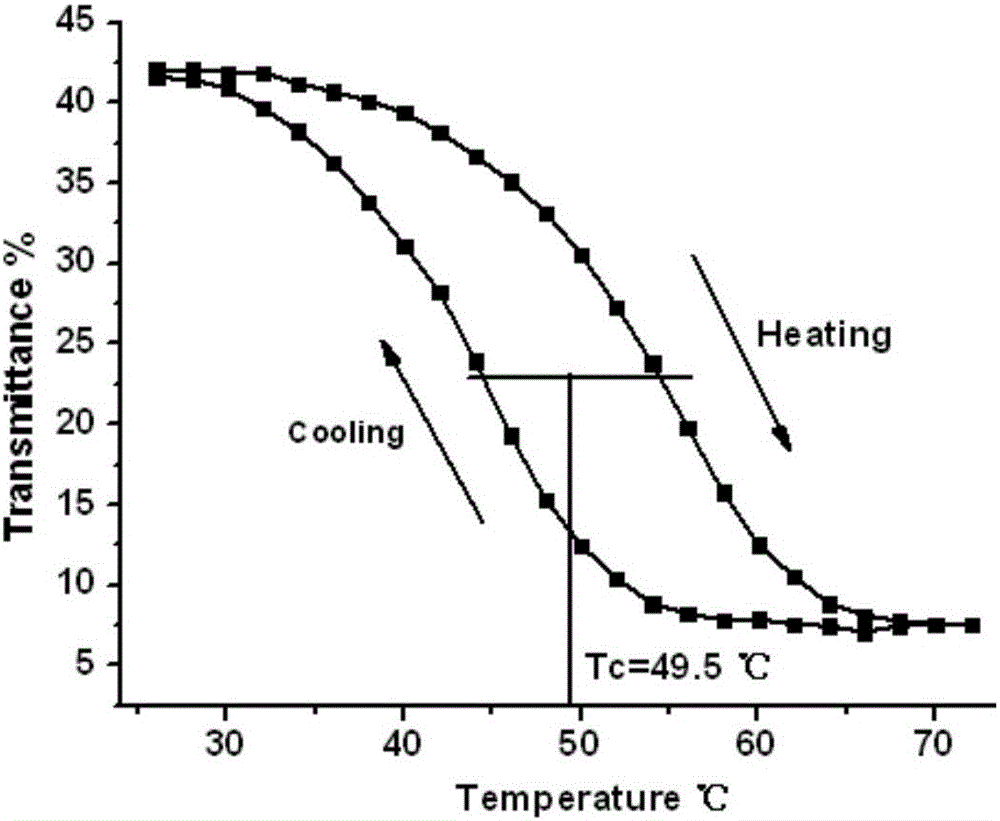

Embodiment 1

[0039] A method for preparing a vanadium oxide film: provide a cleaned tempered glass substrate (G) with a thickness of 3 mm, enter a magnetron sputtering coating vacuum chamber to sputter to form a film at room temperature, and pass through relevant targets in sequence to form G / SiNx / VOx / SiNx film layer structure, send the coated substrate into the vacuum annealing furnace cavity, turn on the vacuum pump group to evacuate to 0.5Pa, fill in Ar gas, make the annealing protection atmosphere in the furnace vacuum to 150Pa, turn on the infrared The radiation lamp is heated, the annealing temperature is 500°C, and it is turned off after heating for 190s. When the temperature of the glass substrate in the vacuum annealing furnace drops to 50°C, the glass substrate is taken out. The obtained phase transition temperature characteristic curve of the vanadium oxide film is shown in figure 1 . Wherein the phase transition temperature is 49.5°C, the definition of the phase transition tem...

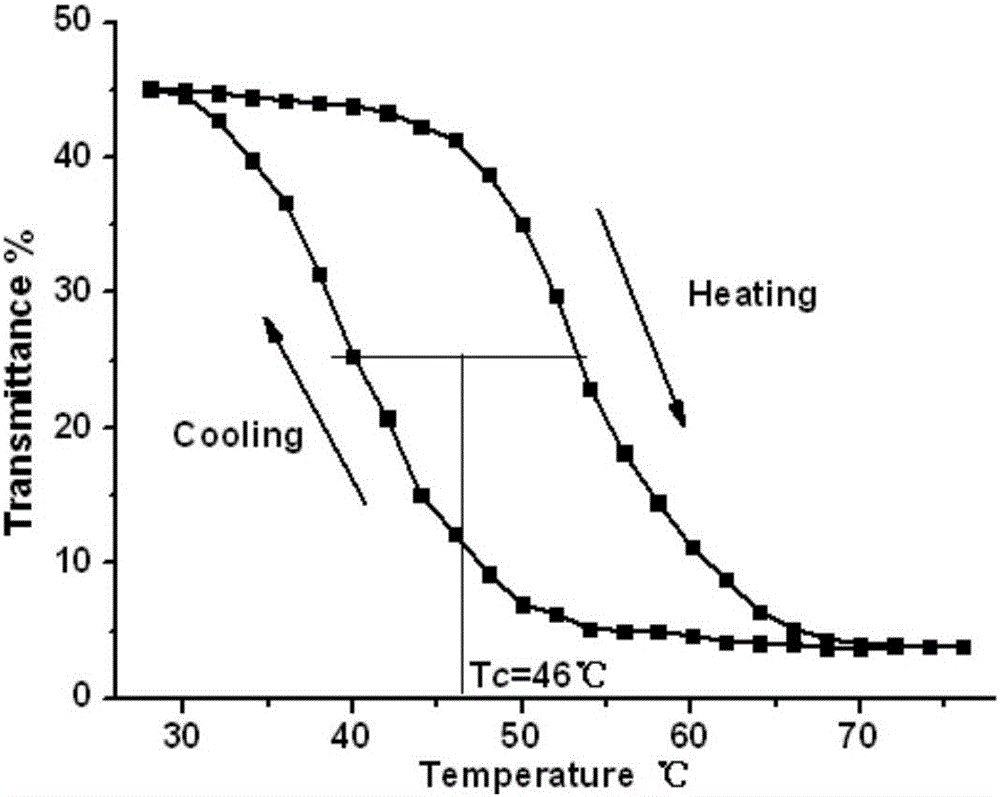

Embodiment 2

[0041] A kind of preparation method of vanadium oxide film layer, present embodiment is compared with embodiment 1, difference is: after coating film substrate is sent into vacuum annealing furnace, background vacuum degree is pumped to 10Pa, is filled with N 2 Atmosphere to annealing protection atmosphere vacuum to 150Pa, turn on the infrared radiation lamp to heat, the annealing temperature is 500°C, turn off after heating for 150s, take out the glass substrate in the vacuum annealing furnace when the temperature drops to 200°C, the obtained vanadium oxide film layer Phase transition temperature characteristic curve see figure 2 , wherein the phase transition temperature is 46°C, the thermal hysteresis curve is steeper than that of Example 1, and the temperature change during the heating phase transition process is about 25°C. At the same time, compared with Example 1 (annealing in an oxygen-free atmosphere), the annealing time of Example 2 is significantly shortened by 40s...

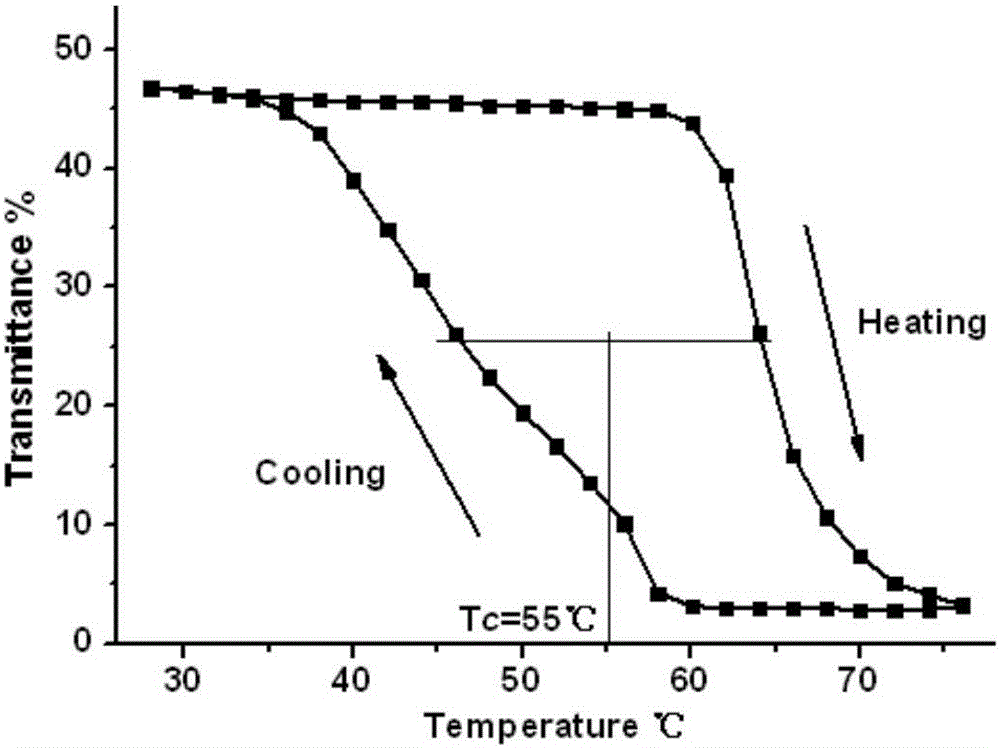

Embodiment 3

[0043] A method for preparing a vanadium oxide film layer. Compared with Example 2, this example differs in that: the background vacuum is evacuated to 300Pa and then annealed directly, the annealing temperature is 400°C, and the heating time is 480s. The phase transition temperature characteristic curve of the vanadium oxide film layer is shown in image 3 . Wherein the phase transition temperature is 55°C, the thermal hysteresis curve is steeper compared to Example 2, and the temperature change during the heating phase transition process is about 10°C. Compared with Example 2, the adjustment difference of the phase transition temperature reaches 9°C . Compared with Examples 2 and 3, for the same precursor film layer, the adjustment of the annealing process atmosphere and related parameters can achieve a relatively large adjustment of the phase transition temperature, and the shape of the thermal hysteresis curve also changes significantly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com