Efficient induced draft fan matched with circulating fluidized bed

A circulating fluidized bed and induced draft fan technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem that the efficiency of ordinary fans cannot reach a high level, and achieve compact structure, high efficiency, and low flow loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

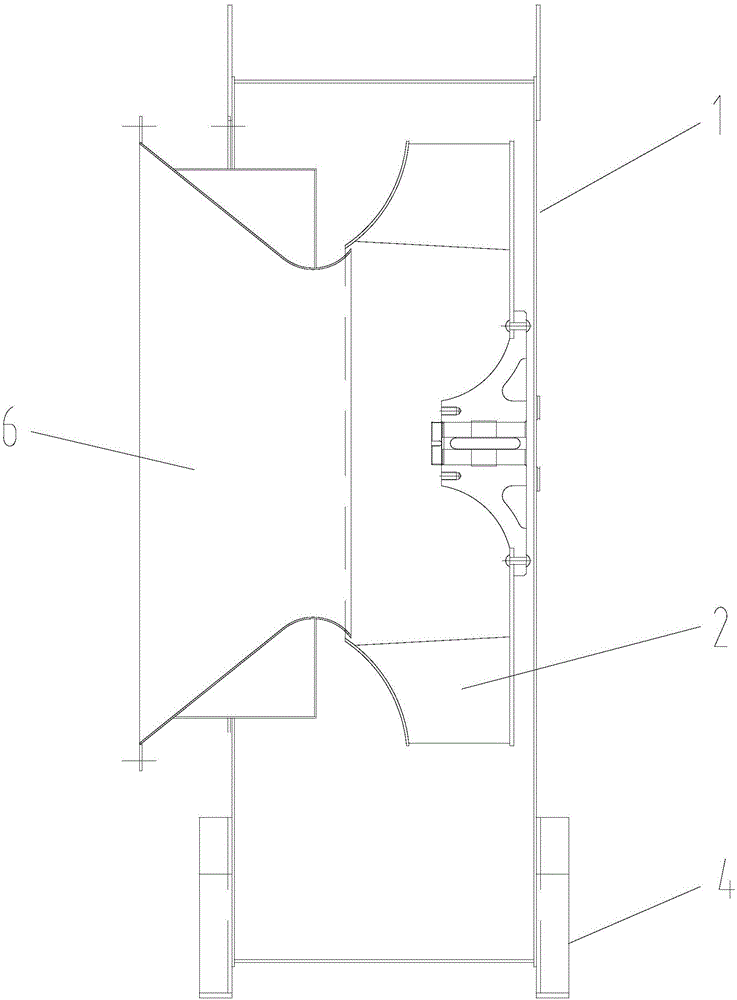

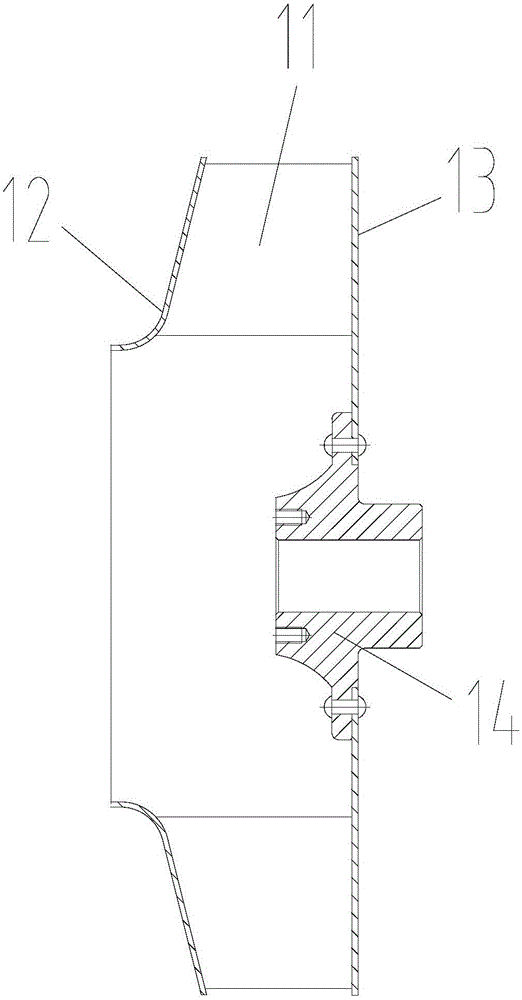

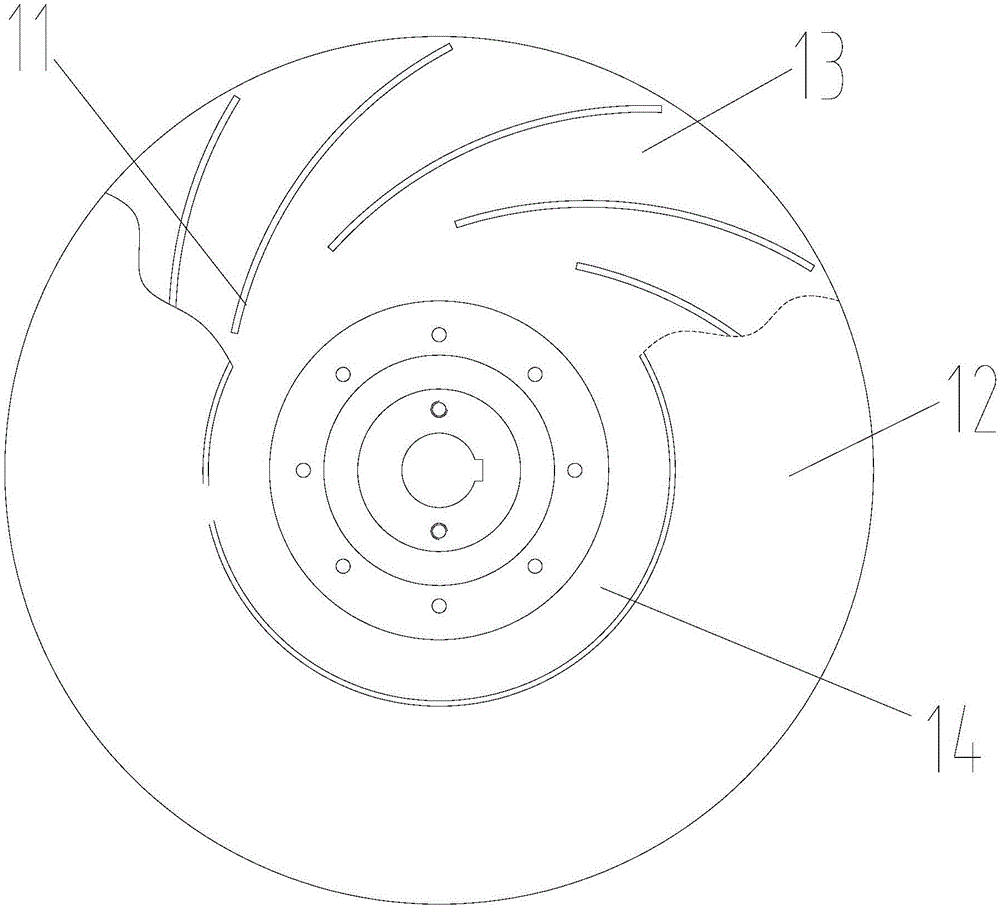

[0013] Embodiment: the dimensional characteristics of No. 6.3 blower fan model:

[0014] 1. The outlet diameter of blade 11 of impeller 2 is 630mm, the inlet diameter is 345mm, the width is 184mm, the outlet width is 112mm, and the outlet angle of blade 11 is 29.3°.

[0015] 2. The air inlet 6 has a diameter of 425mm and a width of 130mm.

[0016] 3. Case 1 is a volute case with a width of 287mm. The distance from the center of the case outlet to the center of the case is 566mm, and the case outlet is 385×287mm.

[0017] 4. The dimensionless performance curve and parameter characteristics: flow coefficient 0.082, pressure coefficient 0.565, fan efficiency 83%, specific A sound level 22.6dB.

[0018] Since the product series are all designed by model simulation, the dimensions of the above-mentioned parts of the impeller 2, the air inlet 6 and the casing 1 are enlarged or reduced to make a series of products, which are all within the protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com