Novel optical fiber fabry-perot ultrasonic hydrophone and manufacturing method thereof

A technology of hydrophone and optical fiber, which is applied in the field of new fiber-optic fiber-optic ultrasonic hydrophone and its production, can solve the problems of limiting interference signal optimization, low reflectivity, difficult optical fiber end face reflectivity, etc., and achieves simple structure and high sensitivity , the effect of high spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

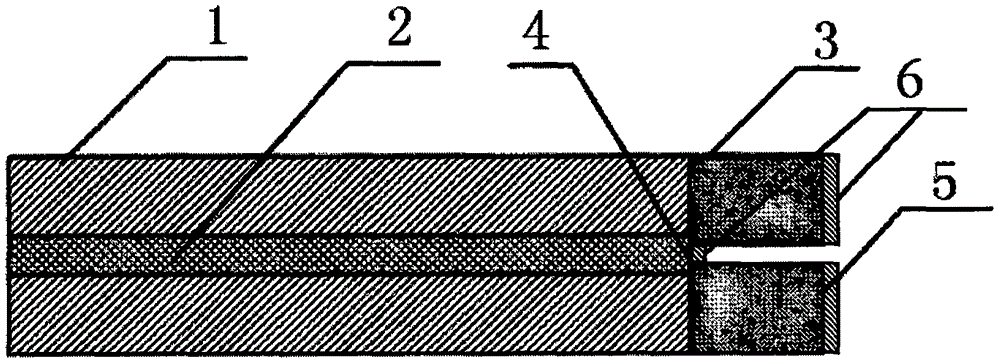

[0046] Step one, such as figure 1 One end of a single-mode optical fiber 1 with an inner diameter of 9 μm and an outer diameter of 125 μm produced by Corning and one end of a quartz capillary 3 with an inner diameter of 5 μm and an outer diameter of 125 μm were cut flat with a fiber optic cutter;

[0047] Step 2. Use the Japanese FITEL S183 optical fiber fusion splicer, adjust the discharge intensity parameters of the optical fiber fusion splicer to 100 and the discharge time to 280ms, discharge once, and weld the cut flat end of the quartz capillary 3 to the flat cut end of the single-mode optical fiber 1;

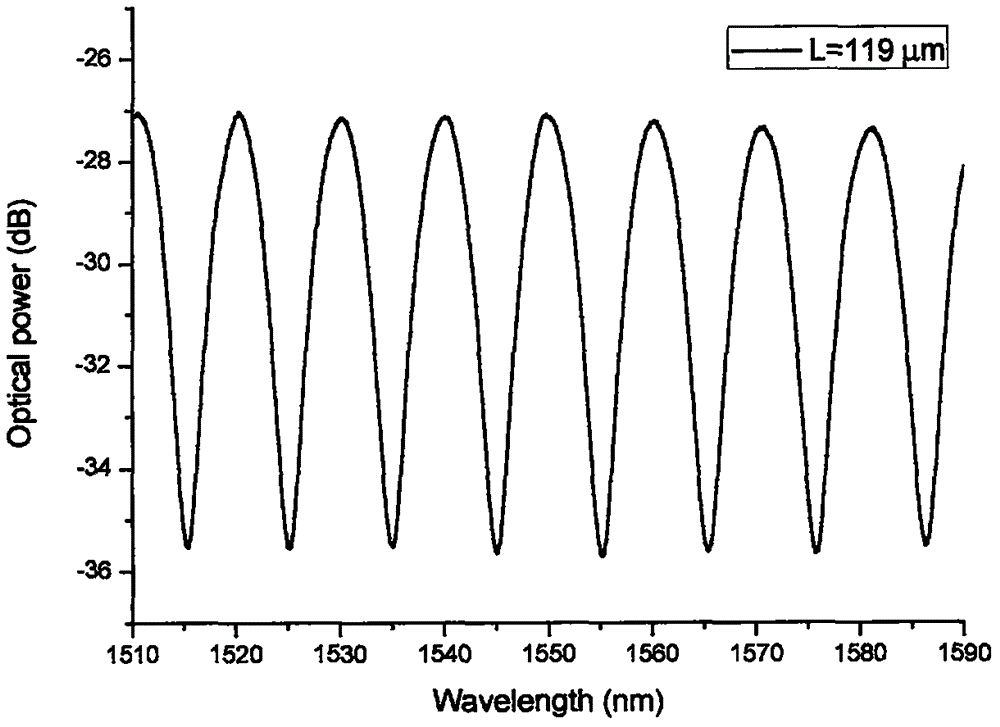

[0048] Step 3. Under a high-power microscope, cut off the quartz capillary with an optical fiber cutter at a distance of 119 μm from the fusion point;

[0049] Step 4: Coating a layer of platinum atomic film 6 with a thickness of 100 nm on the reflective surface 4 and reflective surface 5 by means of atomic layer deposition, so as to obtain a fiber-optic FAPP ultrasonic h...

Embodiment 2

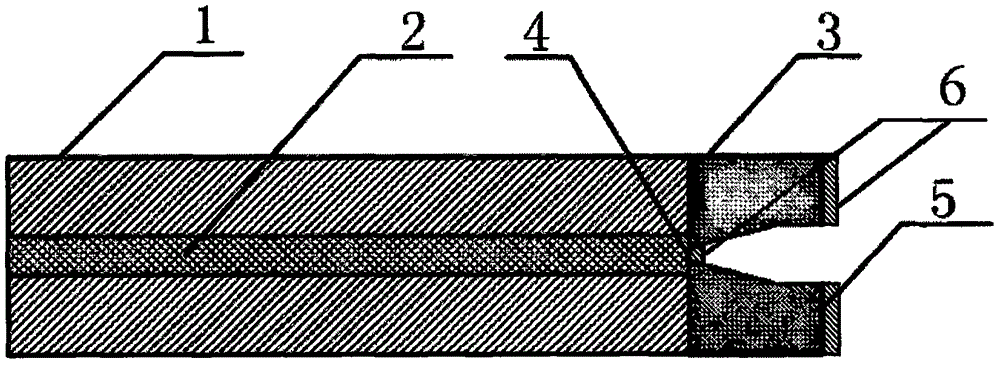

[0051] Step one, such as figure 2 One end of a single-mode optical fiber 1 with an outer diameter of 125 μm and a core of 9 μm produced by Corning and one end of a quartz capillary 3 with an inner diameter of 20 μm and an outer diameter of 125 μm were cut flat with a fiber optic cutter;

[0052] Step 2. Use the Japanese FITEL S183 optical fiber fusion splicer, adjust the discharge intensity parameter of the optical fiber fusion splicer to 100 and the discharge time to 660ms, discharge once, and weld the cut flat end of the quartz capillary 3 to the cut flat end of the single-mode optical fiber 1;

[0053] Step 3. Cut off the quartz capillary 3 with an optical fiber cutter at a distance of 230 μm from the fusion point under a high-power microscope;

[0054] Step 4: Coating a layer of platinum atomic film 6 with a thickness of 100 nm on the reflective surface 4 and reflective surface 5 by means of atomic layer deposition, so as to obtain a fiber-optic FAPP ultrasonic hydrophone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com