Charger automatic testing production device

A technology for automated testing and production equipment, applied to measuring equipment, instruments, measuring electronics, etc., can solve problems such as low product qualification rate, high cost pressure, and unstable output, so as to reduce labor costs, improve efficiency, reduce manpower and The effect of administrative costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

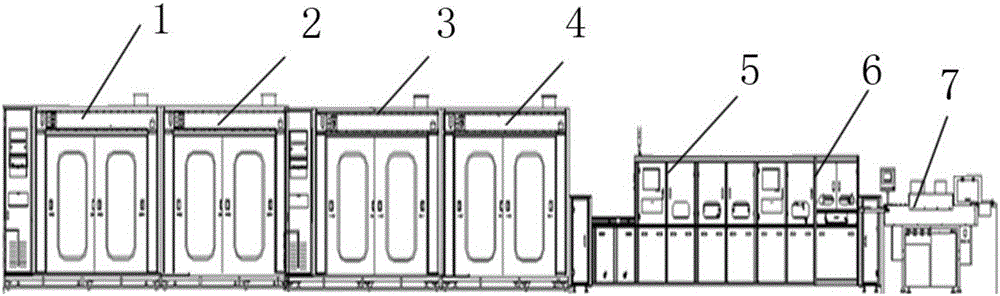

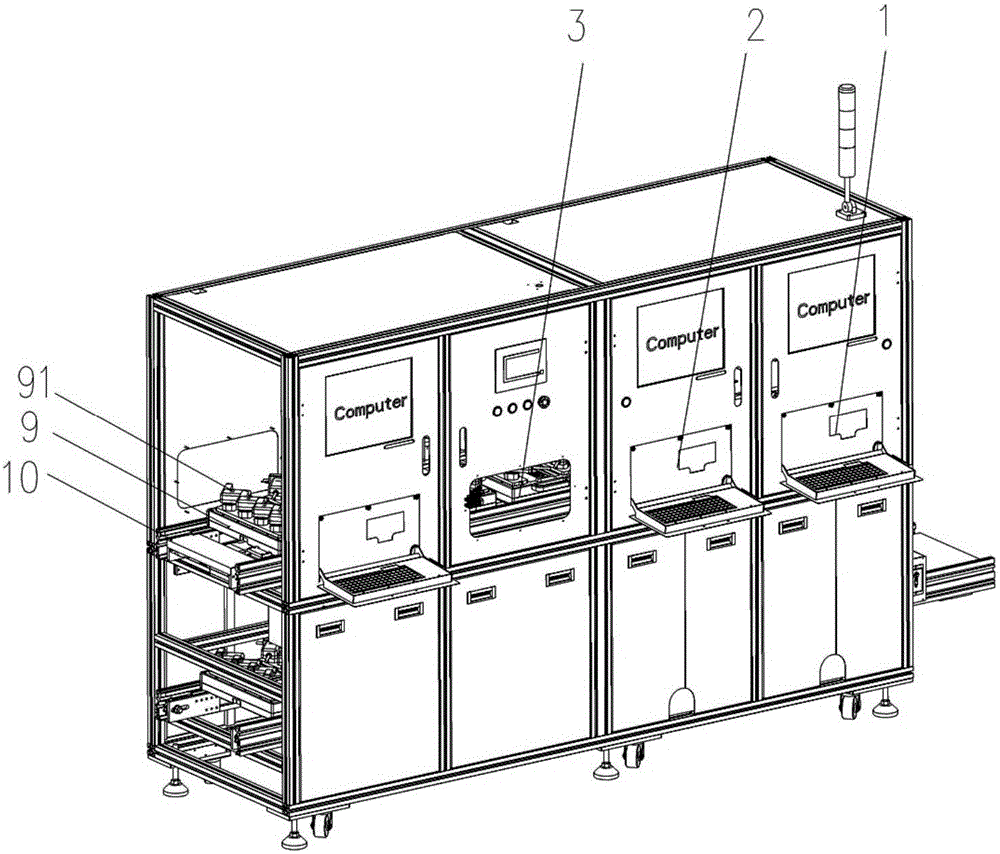

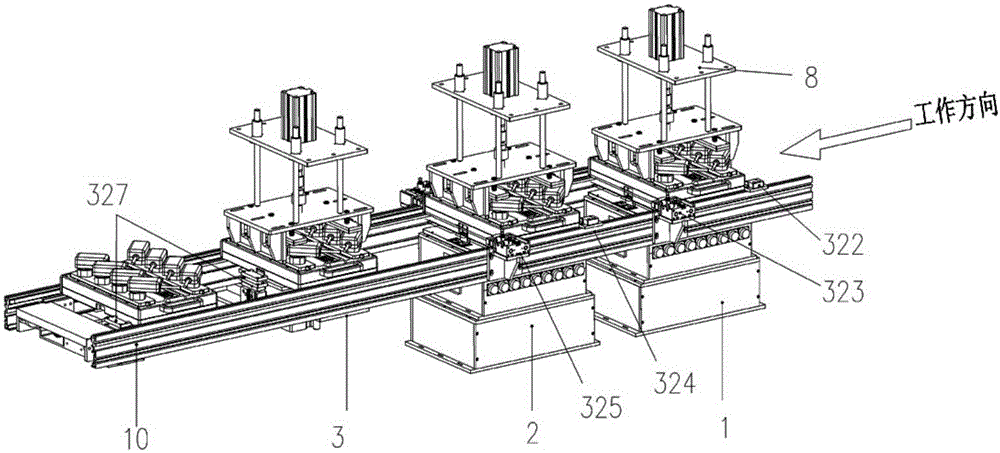

[0029] see Figure 1-13 As shown, the present invention relates to a charger automatic test production device, including a conveying track 10, a carrier 9, a pressing mechanism 8, a high-voltage testing mechanism 1, an ATE testing mechanism 2, a PIN removal mechanism 3, an FCT testing mechanism 4, a point Glue mechanism 5, online ultrasonic film sticking mechanism 6, online laser engraving mechanism 7, the conveying track 10 is set across the high-voltage testing mechanism 1, ATE testing mechanism 2, and the PIN removal mechanism 3, and the carrier 9 is slidably installed On the conveying track 10 and along the conveying track 10, it passes through the high-voltage test mechanism 1, the ATE test mechanism 2, and the PIN removal mechanism 3 in sequence. A pressing mechanism 8 is respectively provided. Both ends of the high-pressure testing mechanism 1 are provided with a high-pressure non-return positioning mechanism 322 and a high-pressure blocking positioning cylinder 323 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com