Method for manufacturing magnesium alloy product

A manufacturing method and technology of magnesium alloys, which are applied in the direction of surface coating liquid devices, coatings, and pre-treated surfaces, etc., can solve problems such as inability to coat coatings, and achieve the effect of improving yield and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Coating applied to magnesium alloy material: A flat test piece (25×50 mm) was prepared from a thixoformed magnesium alloy AZ91D (containing 9% aluminum and 1% zinc). It should be noted that during thixoforming, a mold release agent (polysiloxane-based) is pre-coated on the mold. The test pieces were treated under the conditions in Table 1 to obtain magnesium alloy products. It should be noted that the order of treatment is the order of alkali degreasing treatment, heat treatment, and coating treatment.

[0051] Table 1

[0052] No.

[0053]

[0054] The test piece was dipped in SK18 (manufactured by Jaciu Corporation) set at 60° C. for 5 minutes.

[0055]

[0056] Using an electric furnace, the test piece was heated at the temperature described in Table 1 under atmospheric pressure for 60 minutes. Then let cool to room temperature.

[0057]

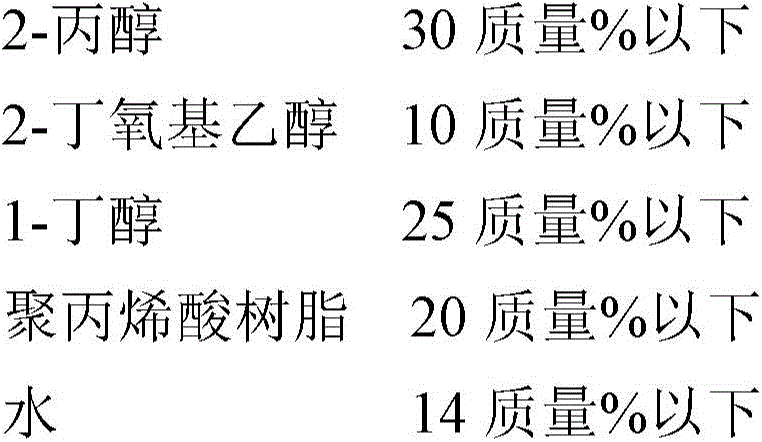

[0058] An acrylic resin-containing polysiloxane-based paint (curing temperature: 160° C.) composed of the fol...

Embodiment 2

[0069] Coating applied to magnesium alloy material: A flat test piece (25×50 mm) was produced from a rolled magnesium alloy AZ31B (containing 3% aluminum and 1% zinc). This test piece was treated under the conditions in Table 3 below to obtain a magnesium alloy product. It should be noted that the conditions for the alkali degreasing treatment, heat treatment, and coating treatment were the same as in Example 1. For the order of treatment, Nos. In order, No. 12 is the order of heat treatment, alkali degreasing treatment, and coating treatment.

[0070] table 3

[0071] No.

[0072] Regarding the test piece obtained above, the same film thickness calculation, 100-grid test and pencil hardness test as in Example 1 were performed. These results are shown in Table 4.

[0073] Table 4

[0074] No.

[0075] Regarding the magnesium alloy material of the rolling material having a composition different from that of Example 1, since the adhesiveness between the p...

Embodiment 3

[0077] Corrosion resistance test: Magnesium alloy products (No.15 and 16) identical to No.4 or No.5 in Example 1 were made from magnesium alloy AZ91D, and the same as No.12 in Example 2 were made from magnesium alloy AZ31B According to the old JIS L0848 test method, these products were immersed in artificial sweat set at 40°C, and after a predetermined period of time, the presence or absence of pitting corrosion was visually checked. In addition, as a comparison, magnesium alloy products (No. 14 (AZ91D), No. 17 to 18 (AZ31B)) were prepared except that no heat treatment was performed or the temperature of the heat treatment was 160° C., and these products were used to Make the same confirmation. These results are shown in Table 5.

[0078] table 5

[0079] No.

[0080] From the above results, it can be known that the corrosion resistance of magnesium alloy products is improved by heat treatment of both magnesium alloys AZ91D and AZ31B. It can also be seen that for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com