Graphene-containing high-strength high-isolation composite latex gloves and preparation method thereof

A composite latex and graphene technology, applied in gloves, clothing, protective clothing, etc., can solve the problems of ordinary latex gloves becoming brittle and discolored, losing stretchability, elasticity and sealing protection, and improving the ability to isolate bacteria and viruses. , The effect of short preparation cycle and stable product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

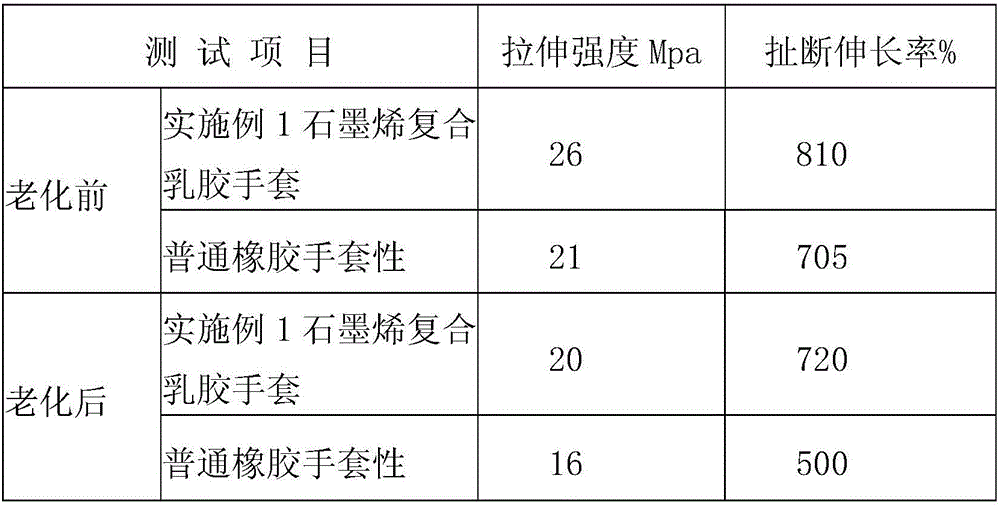

Examples

Embodiment 1

[0016] The high-intensity graphene-containing, high-insulation compound latex gloves of the present embodiment and preparation method thereof comprise the following steps:

[0017] The rubber is first sliced by the rubber mixer, and then sent to the colloidal sol tank and gasoline to mix the sol. After the sol is emulsified and prepared, it is pumped to the latex tundish. The rubber solution dissolved in gasoline is sent from the top of the distillation tower, and is heated and distilled by steam. The light component gasoline is heated into a gas phase, and the gasoline gas is mixed and cooled by cold water in the oil-gas cooler. The oil-water mixture is sent to the oil-water separator, and the oil-water layer is separated. The gasoline in the upper layer is recovered, and the water in the lower part is pumped to the cooling tower for cooling, and then the gas gasoline in the distillation tower is cooled; the latex in the distillation tower is sent to the latex mixing tank ...

Embodiment 2

[0023] A preparation method of graphene-containing high-strength, high-insulation composite latex gloves, comprising the following steps:

[0024] The preparation process of glove raw material latex liquid: the rubber is first sliced by the rubber mixer, and then sent to the colloidal sol tank to mix the sol with gasoline. After the sol is emulsified and prepared, it is pumped to the latex tundish. The rubber solution dissolved in gasoline is sent from the top of the distillation tower, and is heated and distilled by steam. The light component gasoline is heated into a gas phase, and the gasoline gas is mixed and cooled by cold water in the oil-gas cooler. The oil-water mixture is sent to the oil-water separator, and the oil-water layer is separated. The gasoline in the upper layer is recovered, and the water in the lower part is pumped to the cooling tower for cooling, and then the gas gasoline in the distillation tower is cooled; the latex in the distillation tower is sen...

Embodiment 3

[0027] A preparation method of graphene-containing high-strength, high-insulation composite latex gloves, comprising the following steps:

[0028] The preparation process of glove raw material latex liquid: the rubber is first sliced by the rubber mixer, and then sent to the colloidal sol tank to mix the sol with gasoline. After the sol is emulsified and prepared, it is pumped to the latex tundish. The rubber solution dissolved in gasoline is sent from the top of the distillation tower, and is heated and distilled by steam. The light component gasoline is heated into a gas phase, and the gasoline gas is mixed and cooled by cold water in the oil-gas cooler. The oil-water mixture is sent to the oil-water separator, and the oil-water layer is separated. The gasoline in the upper layer is recovered, and the water in the lower part is pumped to the cooling tower for cooling, and then the gas gasoline in the distillation tower is cooled; the latex in the distillation tower is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com