Oxygen-blocking, fresh-keeping and anti-corrosion water-based plastic printing ink and preparation method thereof

A plastic printing and water-based technology, applied in inks, applications, household appliances, etc., can solve the problems of plastic packaging that does not have oxygen barrier, preservation and anticorrosion, damage to the integrity of the coating, environmental hazards, etc., and meets the market demand. Fresh taste, anti-rot and deterioration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

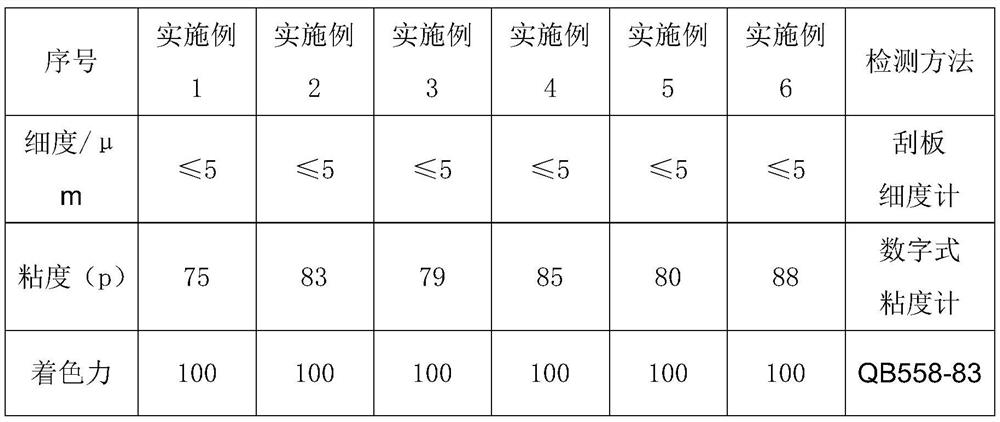

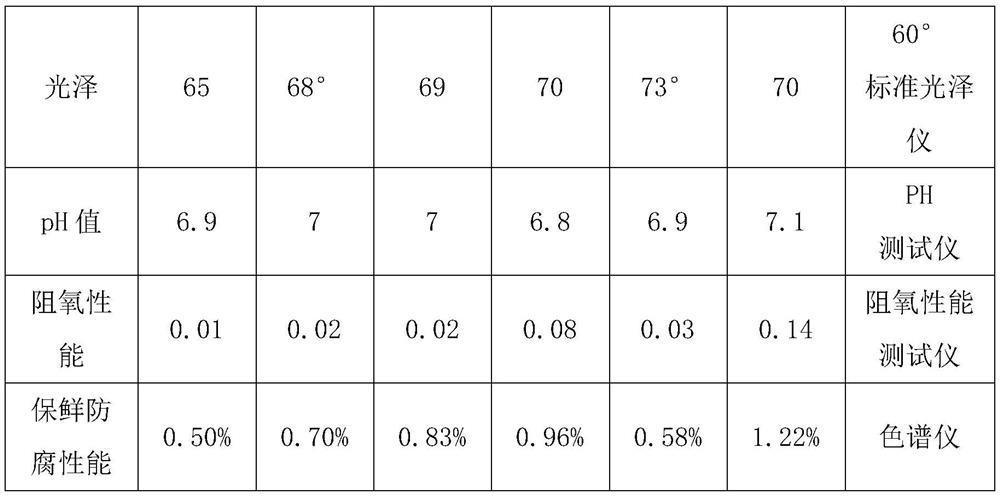

Examples

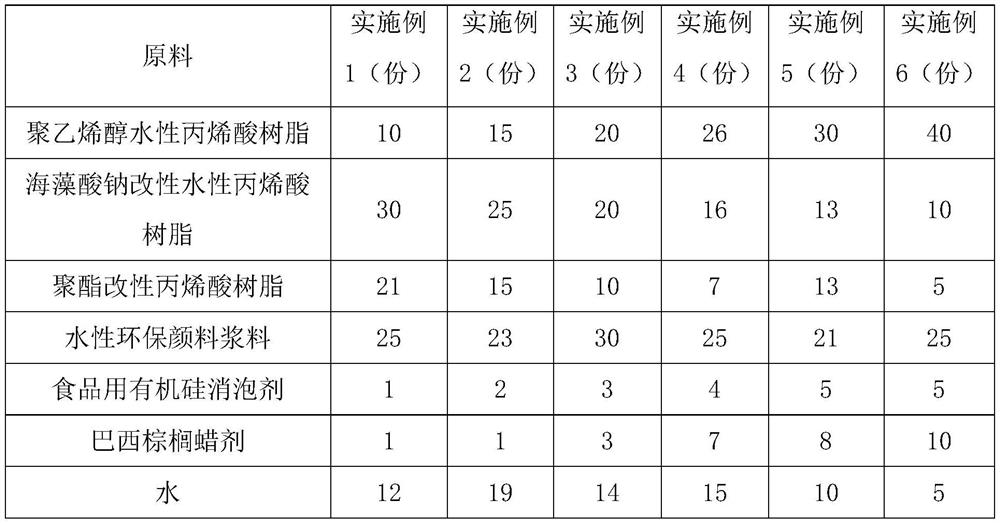

Embodiment 1

[0019] A water-based plastic printing ink for oxygen resistance, freshness preservation and anticorrosion, which consists of the following raw materials in parts by weight:

[0020] 10 parts of polyvinyl alcohol water-based acrylic resin, 30 parts of sodium alginate modified water-based acrylic resin, 21 parts of polyester modified acrylic resin, 25 parts of water-based environmentally friendly pigment slurry, 1 part of food defoamer, 1 carnauba wax 12 parts of water.

Embodiment 2

[0022] A water-based plastic printing ink for oxygen resistance, freshness preservation and anticorrosion, which consists of the following raw materials in parts by weight:

[0023] 15 parts of polyvinyl alcohol water-based acrylic resin, 25 parts of sodium alginate modified water-based acrylic resin, 15 parts of polyester modified acrylic resin, 23 parts of water-based environmentally friendly pigment slurry, 2 parts of food silicone defoamer, carnauba wax 1 part of medicine, 19 parts of water.

Embodiment 3

[0025] A water-based plastic printing ink for oxygen resistance, freshness preservation and anticorrosion, which consists of the following raw materials in parts by weight:

[0026] 20 parts of polyvinyl alcohol water-based acrylic resin, 20 parts of sodium alginate modified water-based acrylic resin, 10 parts of polyester modified acrylic resin, 30 parts of water-based environmentally friendly pigment slurry, 3 parts of food silicone defoamer, carnauba wax 3 parts of agent, 14 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com