A treatment process for waste gas produced by recycling hazardous waste inorganic salts

A treatment process and inorganic salt technology, applied in the field of waste gas treatment process, can solve problems such as pollution and complex sources, and achieve the effects of improving denitrification efficiency, increasing contact time, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

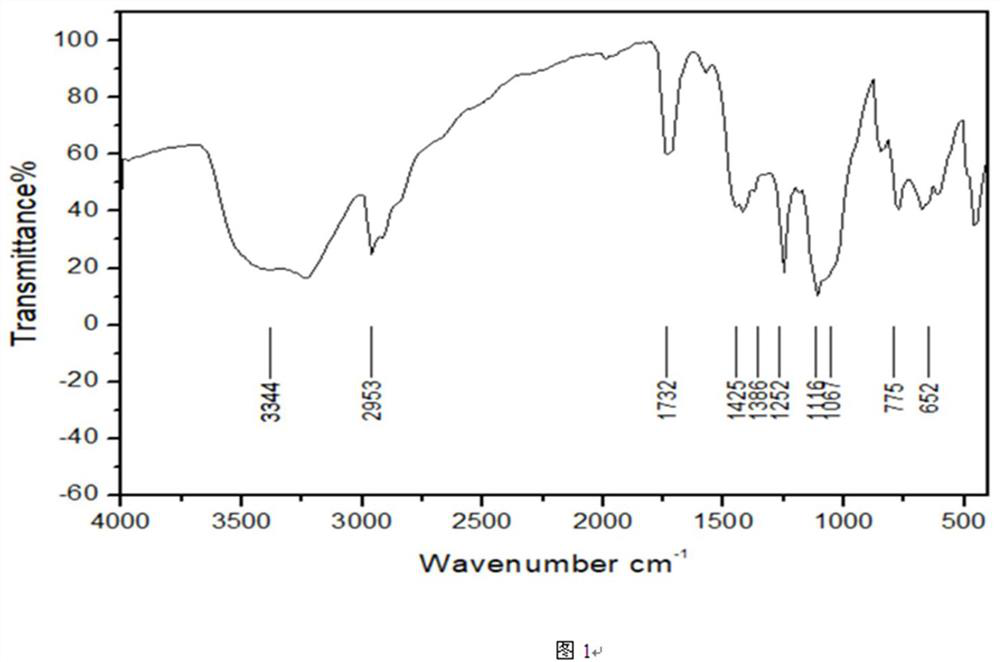

Image

Examples

Embodiment 1

[0034] A treatment process for waste gas produced by recycling hazardous waste inorganic salts. Its technical scheme mainly includes denitrification, quenching, activated carbon adsorption, bag dust removal and deacidification processes, the details are as follows:

[0035] Denitration, the denitrification is carried out in a deep flue gas denitrification device, the temperature of the flue gas from the combustion furnace is 900°C, and the imported flue gas volume is 6800Nm 3 / h, the denitrification agent is sprayed into the denitrification device at a rate of 100kg / h;

[0036] Quenching, the quenching is carried out in a semi-dry quenching tower, the inlet temperature of the flue gas is 500°C, and the flue gas volume is 6000Nm 3 / h, spray 10% calcium hydroxide emulsion at a speed of 300kg / h in the semi-dry quenching tower;

[0037]Activated carbon adsorption, using activated carbon powder sprayed into the Venturi dry reactor to further adsorb most of the dioxins, the inlet t...

Embodiment 2

[0047] A treatment process for waste gas produced by recycling hazardous waste inorganic salts. Its technical scheme mainly includes denitrification, quenching, activated carbon adsorption, bag dust removal and deacidification processes, the details are as follows:

[0048] Denitrification, the denitrification is carried out in the deep flue gas denitrification device, the temperature of the flue gas from the combustion furnace is 1000 °C, and the volume of imported flue gas is 8000Nm 3 / h, the denitrification agent is sprayed into the denitrification device at a rate of 150kg / h;

[0049] Quenching, the quenching is carried out in a semi-dry quenching tower, the inlet temperature of the flue gas is 530°C, and the flue gas volume is 8000Nm 3 / h, spray 13% calcium hydroxide emulsion according to the speed of 400kg / h in the semi-dry quenching tower;

[0050] Activated carbon adsorption, using activated carbon powder sprayed into the Venturi dry reactor to further adsorb most of ...

Embodiment 3

[0060] A treatment process for waste gas produced by recycling hazardous waste inorganic salts. Its technical scheme mainly includes denitrification, quenching, activated carbon adsorption, bag dust removal and deacidification processes, the details are as follows:

[0061] Denitrification, the denitrification is carried out in the deep flue gas denitrification device, the temperature of the flue gas from the combustion furnace is 1050°C, and the imported flue gas volume is 12000Nm 3 / h, the denitrification agent is sprayed into the denitrification device at a rate of 200kg / h;

[0062] Quenching, the quenching is carried out in a semi-dry quenching tower, the inlet temperature of the flue gas is 550°C, and the flue gas volume is 10000Nm 3 / h, spray 15% calcium hydroxide emulsion at a speed of 500kg / h in the semi-dry quenching tower;

[0063] Activated carbon adsorption, using activated carbon powder sprayed into the Venturi dry reactor to further adsorb most of the dioxins, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com