Ceramic-filled epoxy zinc-rich anticorrosive coating material and preparation method thereof

A technology of anti-corrosion coating and filling ring, which is applied in the direction of anti-corrosion coating, epoxy resin coating, coating, etc., and can solve the problems of affecting the bonding force of the upper coating and zinc-rich coating, the decrease of coating anti-corrosion performance, and the decrease of adhesion , to achieve the effect of reducing zinc oxide smoke, enhancing water resistance and corrosion resistance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

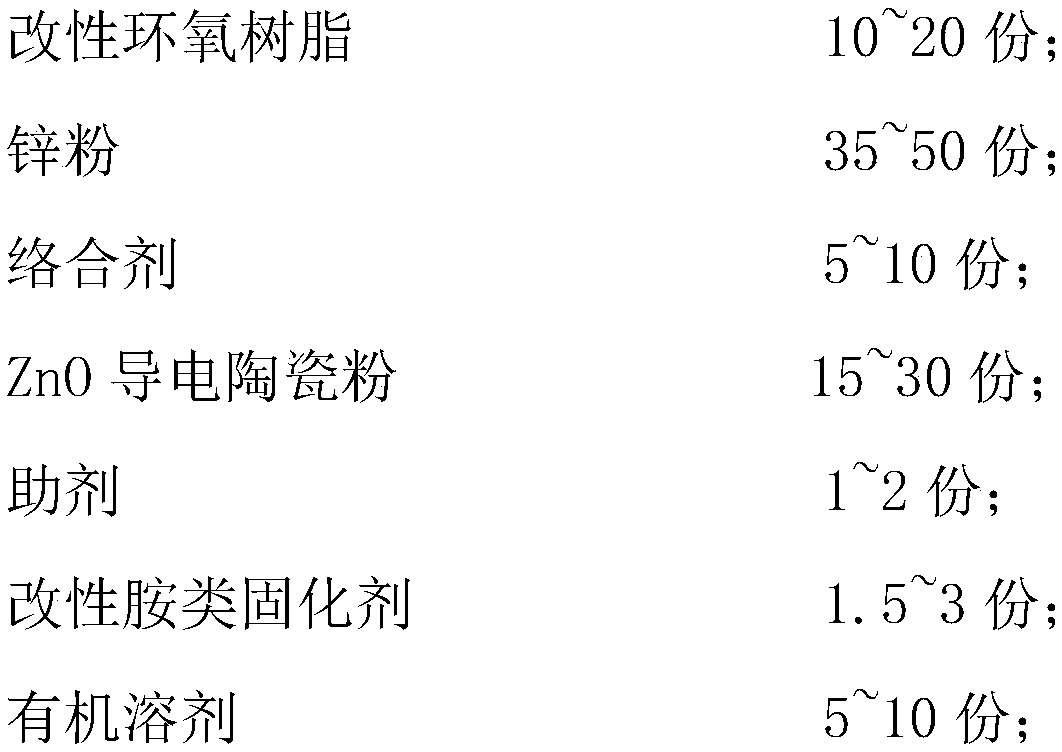

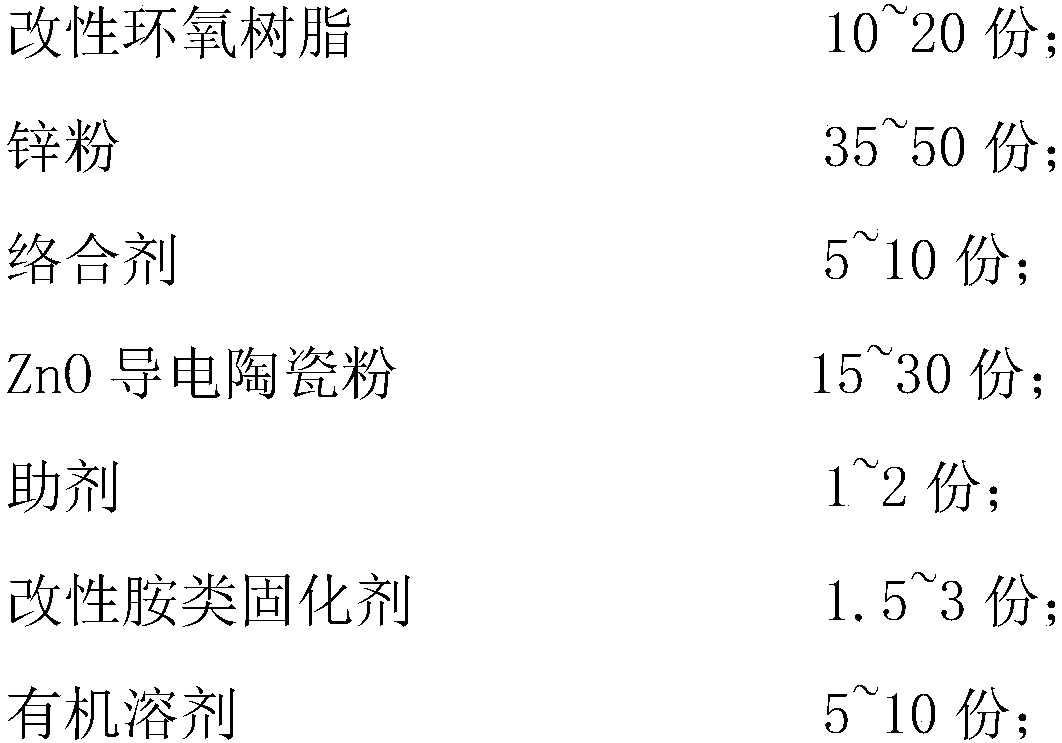

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the ZnO conductive ceramic powder is: analytically pure ZnO, Al 2 o 3 、TiO 2 , MgO according to the mass ratio of 1:0.3: (0.1-1): (0.1-0.8) after the proportion of ingredients, add appropriate distilled water and polyacrylic acid amine dispersant ball milling for 2 hours, then add an appropriate amount of PVA solution to granulate, and then press into The green body, after the green body is debinding, is placed in the air at 1250°C for sintering for 2 hours to obtain ZnO conductive ceramics, and finally the ceramics are crushed and ground into ceramic powder with a particle size of less than 20 μm.

[0033] The complexing agent is one or more of EDTA, CDTA, NTA, EGTA, preferably EDTA. The auxiliary agent includes 0.5-1 part of dispersant, 0.2-0.5 part of defoamer, 0.3-0.5 part of leveling agent, and the dispersant is one of BYK191, BYK190, BYK180 or BYK110 or multiple, the defoamer is one or more of polyoxypropylene glyceryl ether, polyoxypr...

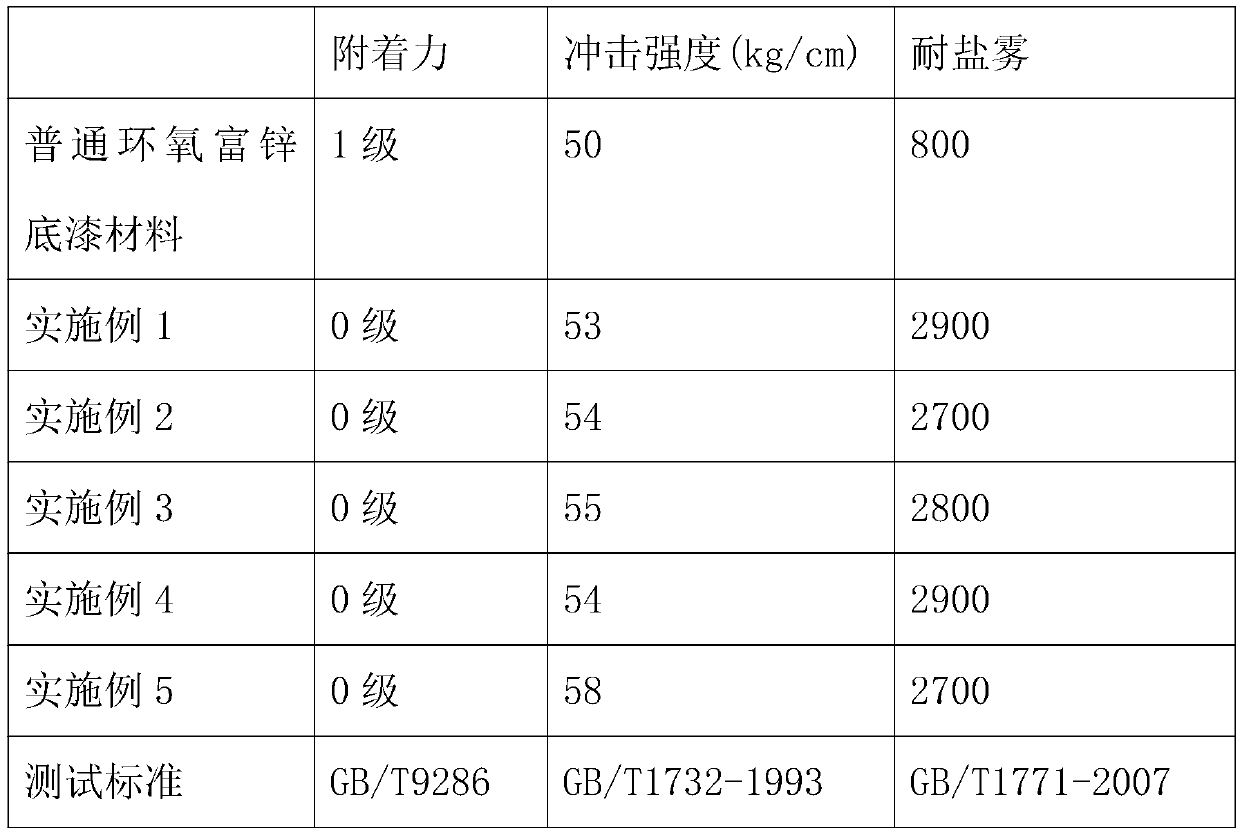

Embodiment 1

[0039](1) Weigh 100kg of epoxy resin (SM6101) and put it into the reaction kettle, stir and heat to 80°C, add 5kg of phthalic anhydride, continue to stir, keep at 80°C for 15 minutes and cool down to obtain the modified phthalic acid epoxy resin;

[0040] (2) Weigh 100kgZnO, 30kgAl 2 o 3 , 10kgTiO 2 , 10kgMgO, add 5kg distilled water and 2kg polyacrylic acid amine dispersant ball milling for 2h, then add 1kgPVA solution to granulate, and then press into a green body, after the green body is degummed, put it in the air and sinter at 1250°C for 2h to get ZnO conductive ceramics, and finally Crush and grind ceramics into ceramic powder with particle size below 20μm;

[0041] (3) Add the above-mentioned ZnO conductive ceramic powder, 50kgEDTA, and 25kg ethylene glycol ether into the reaction kettle, heat to 70°C, continue to stir and keep warm for 5 hours, and then cool down;

[0042] (4) Weigh 15kg polyamide curing agent, 5kg BYK191, 2kg polyoxypropylene glyceryl ether, 3kg p...

Embodiment 2

[0044] (1) Weigh 100kg of epoxy resin (SM6101) and put it into a reaction kettle, stir and heat to 80°C, add 8kg of phthalic anhydride, continue to stir, keep warm at 80°C for 15 minutes and cool down to obtain phthalic acid modified epoxy resin;

[0045] (2) Weigh 110kgZnO, 33kgAl 2 o 3 , 11kgTiO 2 , 11kgMgO, add 5kg distilled water and 2kg polyacrylic acid amine dispersant ball milling for 2h, then add 1kgPVA solution to granulate, and then press into a green body, after the green body is degummed, put it in the air for sintering at 1250°C for 2h to get ZnO conductive ceramics, and finally Crush and grind ceramics into ceramic powder with particle size below 20μm;

[0046] (3) The ZnO conductive ceramic powder obtained in step (2) and 60kgEDTA and 25kg ethylene glycol ether are added to the reactor, heated to 75°C, and cooled after 8 hours of continuous stirring and heat preservation reaction;

[0047] (4) Weigh 15kg polyamide curing agent, 5kg BYK190, 2kg polyoxypropyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com