A polyolefin/vinylpyridine-based shape memory elastomer and its preparation method

A vinylpyridine-based and polyvinylpyridine technology, which is applied in the field of polyolefin/vinylpyridine-based shape memory elastomers and their preparation, can solve problems such as shape memory properties that have not yet been involved, and achieves sensitive response to temperature stimulation and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Slowly add 0.1mol of carboxyl-terminated polybutadiene into 200ml of toluene, and fully dissolve it by mechanical stirring to obtain solution A;

[0024] (2) Slowly add 2 mol of polyvinylpyridine into 250 ml of toluene, and fully dissolve it by mechanical stirring to obtain solution B;

[0025] (3) Mix the solution A with the solution B, stir for 24 hours, use a rotary evaporator to remove most of the solvent, and then vacuum dry at 45° C. for 24 hours to remove the remaining solvent to obtain an elastomer;

[0026] (4) The elastomer was molded at 120° C. to obtain a polyolefin / vinylpyridine-based shape-memory elastomer.

[0027] The shape-memory elastomer prepared by the present invention needs to undergo a crosslinking reaction under ultraviolet light irradiation, and the shape-memory elastomer after crosslinking has better mechanical strength, elastic properties and higher recovery rate.

Embodiment 2

[0029] (1) After mixing 0.1mol of carboxy-terminated polybutadiene and 0.1mol of zinc acetate, slowly add it to 300ml of toluene, and fully dissolve it by mechanical stirring to obtain solution A;

[0030] (2) Slowly add 0.1mol of polystyrene-polyvinylpyridine copolymer into 250ml of toluene, and fully dissolve it by mechanical stirring to obtain solution B;

[0031] (3) Mix the solution A with the solution B, stir for 30 hours, use a rotary evaporator to remove most of the solvent, and then vacuum dry at 45° C. for 28 hours to remove the remaining solvent to obtain an elastomer;

[0032] (4) The elastomer was molded at 130° C. to obtain a polyolefin / vinylpyridine-based shape-memory elastomer.

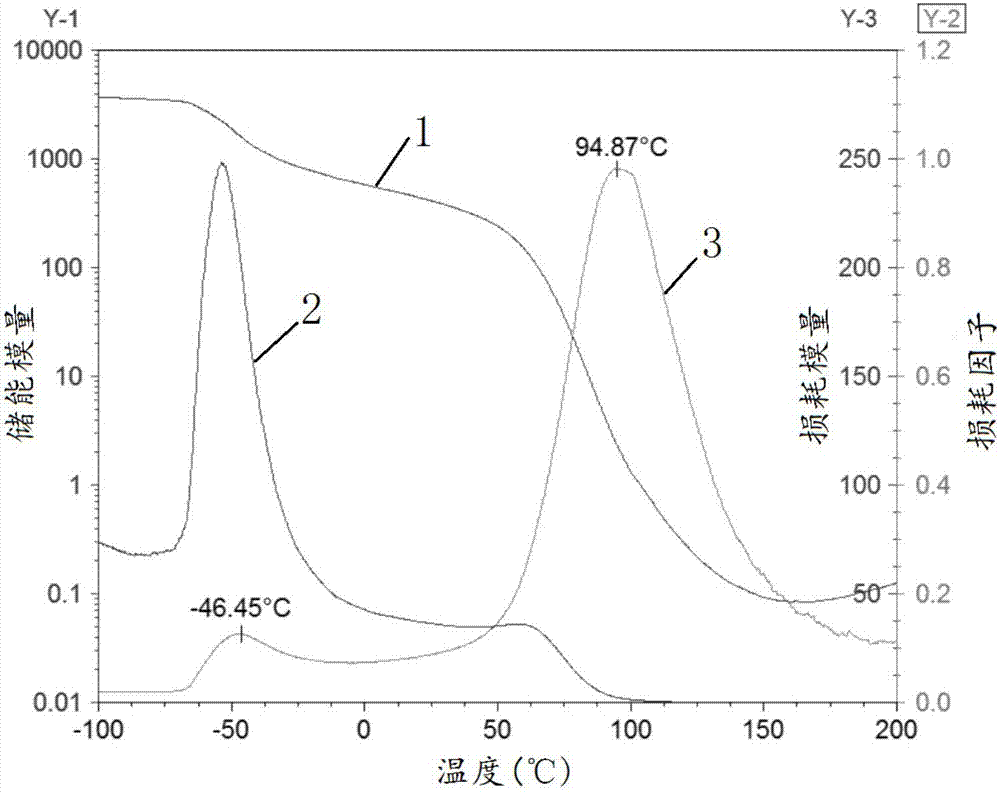

[0033] like figure 1 As shown, curve 1 is the storage modulus of the shape-memory elastomer with temperature variation curve, curve 2 is the loss modulus of the shape-memory elastomer with temperature variation curve, and curve 3 is the shape-memory elastic The variation curve of the...

Embodiment 3

[0035] (1) After mixing 0.1mol of carboxy-terminated polyethylene and 0.09mol of copper acetate, slowly add it to 300ml of tetrahydrofuran, and fully dissolve it by mechanical stirring to obtain solution A;

[0036] (2) Slowly add 0.08mol of sodium acrylate-vinylpyridine copolymer into 250ml of tetrahydrofuran, and fully dissolve it by mechanical stirring to obtain solution B;

[0037] (3) Mix the solution A with the solution B, stir for 35 hours, use a rotary evaporator to remove most of the solvent, and then vacuum dry at 46° C. for 30 hours to remove the remaining solvent to obtain an elastomer;

[0038] (4) The elastomer was molded at 135° C. to obtain a polyolefin / vinylpyridine-based shape-memory elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com