Preparation of softly magnetic granules for injection molding

A technology of injection molding and pellets, applied in the field of preparation of soft magnetic pellets, can solve the problems of complex process and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

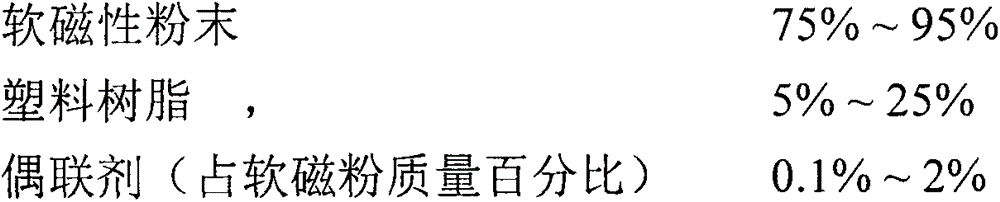

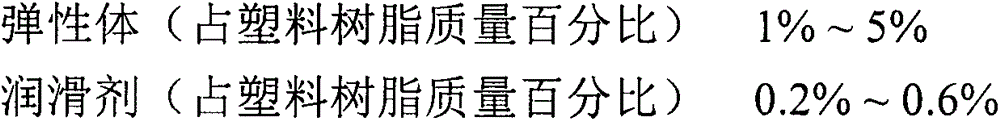

Method used

Image

Examples

Embodiment 1

[0015] Take 11.25g of silane coupling agent KH-550 and dissolve it in an appropriate amount of absolute ethanol. After it is completely dissolved, add 4.5kg of iron powder. After stirring evenly, dry it in vacuum at 60°C for 4-6 hours, cool, pulverize, and sieve Separate the coupled iron powder.

[0016] Take 0.5kg of PA66, add 0.2% lubricant and 5% elastomer, mix evenly, and premix with 4.5kg of the above-mentioned coupled iron powder to obtain a premix.

[0017] The above premixed materials were mixed and granulated by a twin-screw extruder to obtain iron powder / PA66 injection molding pellets. The temperature of each section of the extruder was set at 245°C, 250°C, 260°C, and 245°C.

[0018] The above pellets were injection molded to obtain samples. According to relevant test standards, the measured magnetic permeability of the sample is 18, the saturation magnetization is 18.3mT, and the core loss Pcv is 32.3kW / m 3 .

Embodiment 2

[0020] Take 22.75g of titanate coupling agent HY-201 and dissolve it in an appropriate amount of absolute ethanol. After it is completely dissolved, add 4.55kg of iron-nickel alloy powder. After stirring evenly, dry it in vacuum at 80°C for 4 hours, then cool and pulverize and sieving to obtain coupled iron-nickel alloy powder.

[0021] Take 0.45kg of PPS, add 0.1% lubricant and 4% elastomer, mix evenly, and mix with 4.55kg of the above-mentioned coupled iron-nickel alloy powder to obtain a premix.

[0022] The above premixed materials were kneaded and granulated by a twin-screw extruder to obtain iron-nickel alloy / PPS injection molding pellets. The temperature of each section of the extruder was set at 245°C, 250°C, 260°C, and 245°C.

[0023] The above pellets were injection molded to obtain samples. According to relevant test standards, the measured magnetic permeability of the sample is 27, the saturation magnetization is 22.5mT, and the magnetic core loss is Pcv45.6kW / m ...

Embodiment 3

[0025] Take 12.75g of silane coupling agent KH-560 and dissolve it in an appropriate amount of absolute ethanol. After it is completely dissolved, add it to 4.25kg of manganese zinc ferrite. Grinding and sieving to obtain coupled manganese zinc ferrite powder.

[0026] Take 0.75kg of PA6, add 0.3% lubricant and 4% elastomer, mix evenly, and premix with 4.25kg of the above-mentioned coupled manganese zinc ferrite powder to obtain a premix.

[0027] The above premixed materials were mixed and processed by a twin-screw extruder to obtain manganese zinc ferrite / PA6 injection molding pellets. The temperature of each section of the extruder was set at 245°C, 250°C, 260°C, and 245°C.

[0028] The above pellets were injection molded to obtain samples. According to the relevant standard test, the measured magnetic permeability of the sample is 14, the saturation magnetization is 18.4mT, and the core loss Pcv is 46.7kW / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com