Graphene, CNT (carbon nano tube) and bio-based nylon ternary composite material and preparation method thereof

A bio-based nylon and graphene carbon technology, applied in the field of nylon composite materials, can solve the problems of low low-temperature impact strength and poor heat resistance, and achieve excellent performance, increase biocompatibility, excellent mechanical properties and electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Preparation of graphene carbon nanotube bio-based nylon ternary composite material by in-situ polymerization

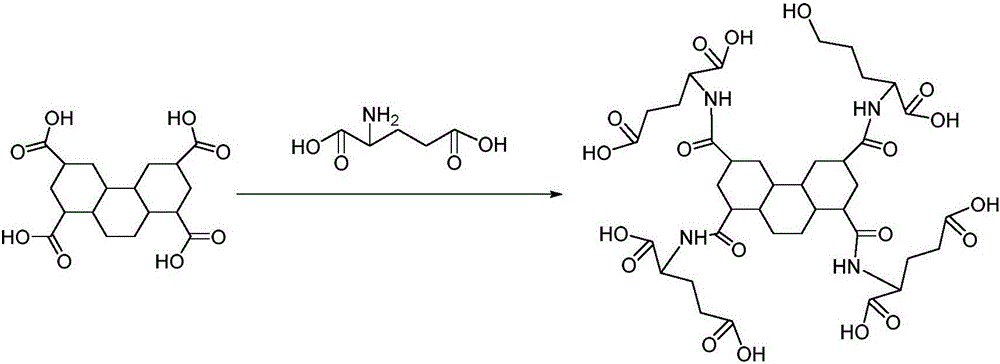

[0049] (1) Combination of amino acid and graphene:

[0050] Weigh 50 mg of carboxylated graphene, and ultrasonically disperse the carboxylated graphene in ethanol to obtain a uniformly dispersed carboxylated graphene suspension; then add 5 times the mass of glutamic acid, and ultrasonicate for 30 minutes at 50°C to make the amino acid and graphite Graphene was mixed evenly, and then kept in a microwave reactor at 50°C to continue the ultrasonic reaction for 10 minutes to obtain a mixed solution of glutamic acid and carboxylated graphene bonded to each other.

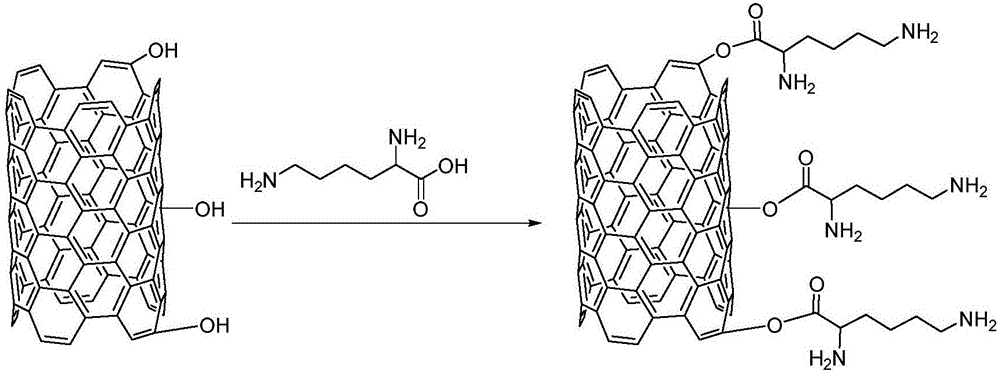

[0051] (2) Compounding of amino acid and carbon nanotubes:

[0052] Weigh 50 mg of hydroxylated carbon nanotubes, and ultrasonically disperse the hydroxylated carbon nanotubes in ethanol to obtain a uniformly dispersed suspension of hydroxylated carbon nanotubes; The tubes were mixed evenly, a...

Embodiment 2

[0057] Example 2 Preparation of graphene carbon nanotube bio-based nylon ternary composite material by in-situ polymerization

[0058] (1) Combination of amino acid and graphene:

[0059] Weigh 50 mg of carboxylated graphene, and ultrasonically disperse the carboxylated graphene in ethanol to obtain a uniformly dispersed carboxylated graphene suspension; then add 3 times the mass of glutamic acid, and ultrasonically 30 minutes to mix the amino acid and graphene evenly , and then let it maintain 50° C. in a microwave reactor and continue ultrasonic reaction for 10 minutes to obtain a mixed solution of glutamic acid and carboxylated graphene bonded to each other.

[0060] (2) Compounding of amino acid and carbon nanotubes:

[0061] Weigh 50 mg of hydroxylated carbon nanotubes, and ultrasonically disperse the hydroxylated carbon nanotubes in ethanol to obtain a uniformly dispersed suspension of hydroxylated carbon nanotubes; The nanotubes were mixed evenly, and then kept in a m...

Embodiment 3

[0066] Example 3 Preparation of graphene carbon nanotube bio-based nylon ternary composites by in-situ polymerization

[0067] (1) Combination of amino acid and graphene:

[0068] Weigh 50 mg of carboxylated graphene, and ultrasonically disperse the carboxylated graphene in ethanol to obtain a uniformly dispersed carboxylated graphene suspension; then add 3 times the mass of glutamic acid, and ultrasonically 30 minutes to mix the amino acid and graphene evenly , and then let it maintain 50° C. in a microwave reactor and continue ultrasonic reaction for 10 minutes to obtain a mixed solution of glutamic acid and carboxylated graphene bonded to each other.

[0069] (2) Compounding of amino acid and carbon nanotubes:

[0070] Weigh 50 mg of hydroxylated carbon nanotubes, and ultrasonically disperse the hydroxylated carbon nanotubes in ethanol to obtain a uniformly dispersed suspension of hydroxylated carbon nanotubes; The nanotubes were mixed evenly, and then kept in a microwave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com