Heat treatment method of ausferrite nodular cast iron

A ductile iron and austenitic technology, applied in the field of warm quenching, can solve the problems of low production efficiency, low cooling capacity of castings and high cost, and achieve the effect of improving production efficiency and ensuring output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

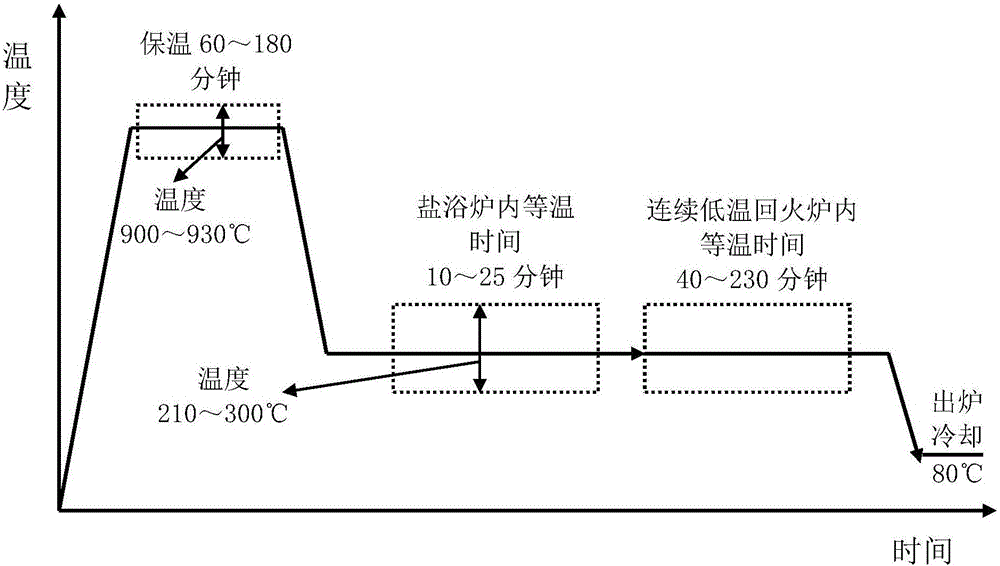

[0027] The first step, high temperature austenitization treatment:

[0028] First, place the carbide-containing ductile iron castings-semi-autogenous mill austeric ductile iron balls in batches into continuous high-temperature Carry out high-temperature austenitization in the furnace. The weight of each batch of semi-autogenous austenitic ductile iron grinding balls is 350 kg, and the austenitization temperature is 920±10°C. After holding for 100 minutes, transfer to the next step The first stage isothermal quenching heat treatment is carried out in the salt solution isothermal salt bath furnace;

[0029] The second step, the first stage of austempering heat treatment:

[0030] Place the austenitic nodular cast iron grinding balls of the semi-autogenous mill that have been treated in the first step of high-temperature austenitization in an isothermal salt-bath furnace with a weight of 9 tons and a temperature of 250±3°C. According to the wall thickness or modulus of the ausfer...

Embodiment 2

[0037] First, according to the total amount of ductile iron castings to be processed, the ductile iron castings are placed in batches in a continuous high-temperature furnace for high-temperature austenitization. The weight of each batch of ductile iron castings is 300 kg, and the austenitization The temperature is 900°C, after 60 minutes of heat preservation, it is transferred to the next step of isothermal salt bath furnace with nitrate solution for the first stage of isothermal quenching heat treatment;

[0038] The second step, the first stage of austempering heat treatment:

[0039] Place the ductile iron castings treated with high-temperature austenitization in the first step in an isothermal salt bath furnace with a weight of 8 tons and a temperature of 210°C. The isothermal time in the bath furnace is 10 minutes, that is to complete the first stage isothermal quenching heat treatment of ductile iron castings in the salt bath furnace;

[0040] The third step, the secon...

Embodiment 3

[0045] The first step, high temperature austenitization treatment:

[0046] First, put the ductile iron castings containing carbides in batches into a continuous high-temperature furnace for high-temperature austenitization according to the total amount of ductile iron castings to be processed. The weight of each batch of ductile iron castings containing carbides For 500 kg, the austenitizing temperature is 930°C, after 180 minutes of heat preservation, transfer to the next step of nitrate solution isothermal salt bath furnace for the first stage of isothermal quenching heat treatment;

[0047] The second step, the first stage of austempering heat treatment:

[0048] Place the carbide-containing ductile iron castings treated in the first step of high-temperature austenitization in an isothermal salt-bath furnace with a weight of 12 tons and a temperature of 300°C. Thickness or modulus size, the isothermal time in the salt bath furnace is determined to be 25 minutes, that is, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com