Modularized building

A modular and architectural technology, applied in the direction of architecture and building structure, can solve the problems of inability to guarantee the bearing capacity of modular buildings, affecting the use area of indoor space, inconvenient to disassemble, etc. The effect of disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

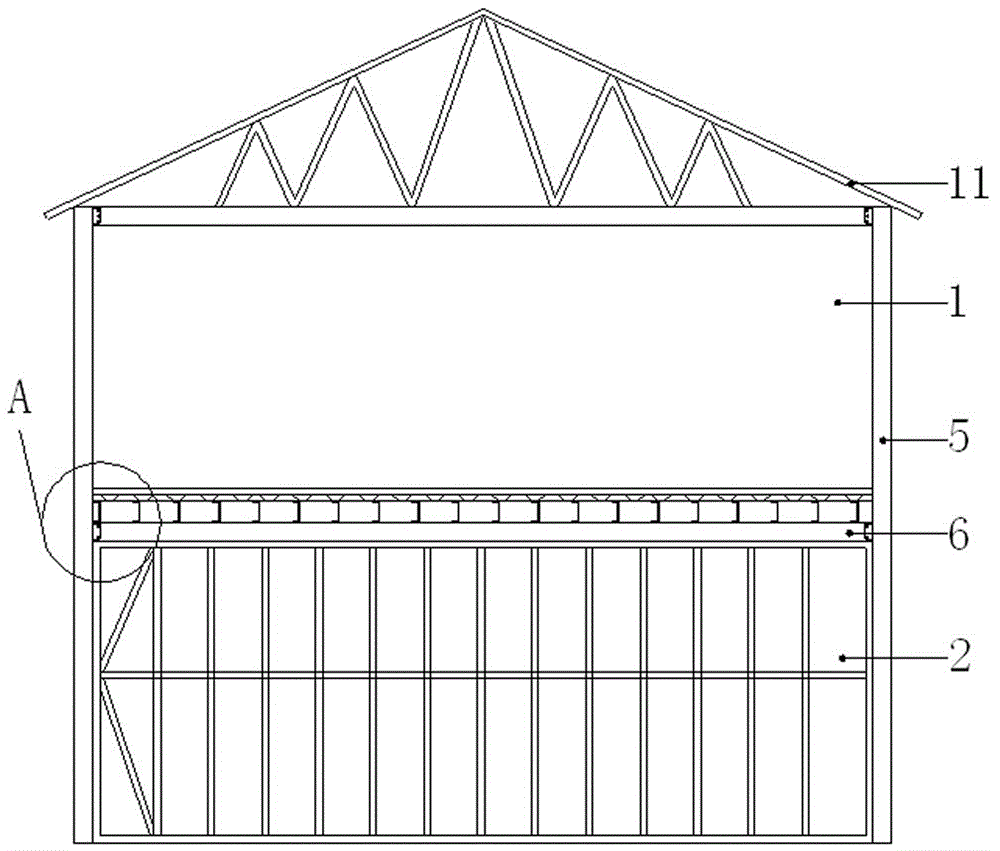

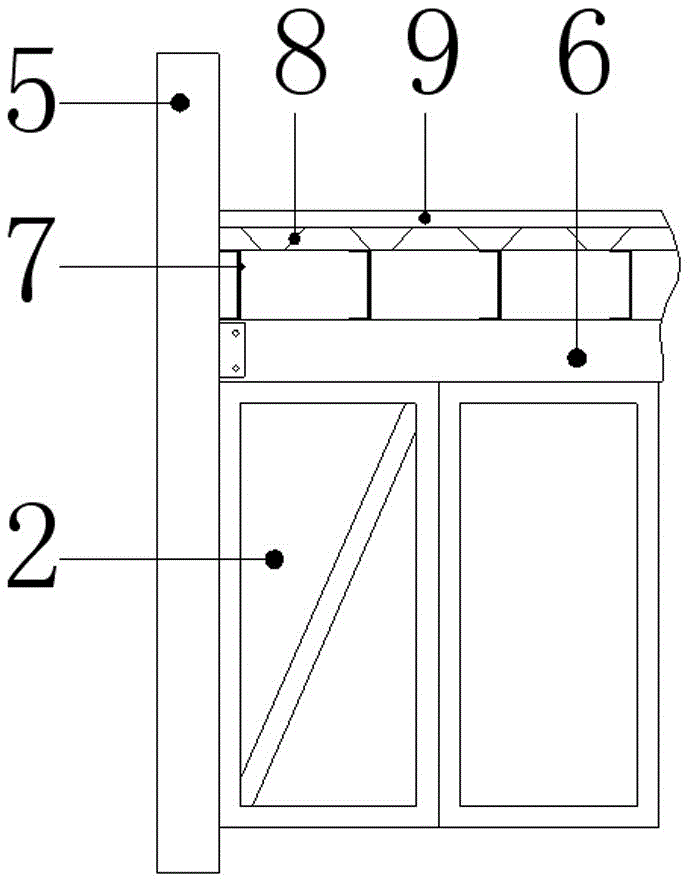

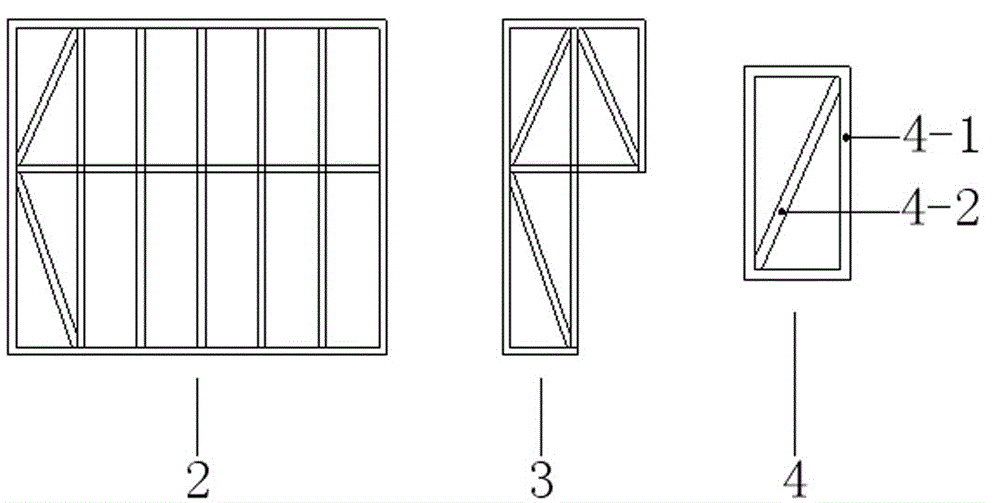

[0039] Embodiment 1: as Figure 1-5 As shown, the present invention discloses a modular building, which includes multi-layer building units 1 stacked up and down; each layer of building units 1 includes a wall formed by a supporting frame; the supporting frame includes a plurality of light steel wall frames 2, set The heavy steel square tube 5 at the intersection of two adjacent light steel wall frames 2, the wall panels fixed on the outside and inside of the light steel wall frame 2 and the middle layer filled in the light steel wall frame 2, namely: Fill the intermediate layer between the exterior and interior siding. Among them: the heavy steel square pipes of adjacent two-story building units can use the same heavy steel square pipe, and the height of the heavy steel square pipe is the height of the modular building; the heavy steel square pipes of adjacent two-story building units can be used in each One-story building units use separate heavy-steel square pipes, which a...

Embodiment 2

[0047] Embodiment 2: The present invention also discloses a construction method of a modular building, the structure of the modular building includes multi-storey building units, and the method includes:

[0048] S101: According to the appearance and mechanical performance requirements of the modular building design, assemble multiple light steel wall frames required for each building unit, select the number of module groups required to construct the light steel wall frame, and the module units in the module group The number and size of the first keel and the second keel in the module unit, the number and size of heavy steel square tubes, the number and size of heavy steel support beams, the number and size of light steel brackets, and the number of light steel corrugated plates and size; the first keel, the second keel, heavy steel square tube, heavy steel support beam, light steel bracket and light steel corrugated board are prefabricated in the factory and assembled without ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com