Bamboo rib ring type spherical reticulated shell and method

A technology of rib ring and reticulated shell, which is applied in the structural form of the main structural spherical reticulated shell, can solve problems such as difficulty in use, and achieve the effects of simple building demolition, improved mechanical performance, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

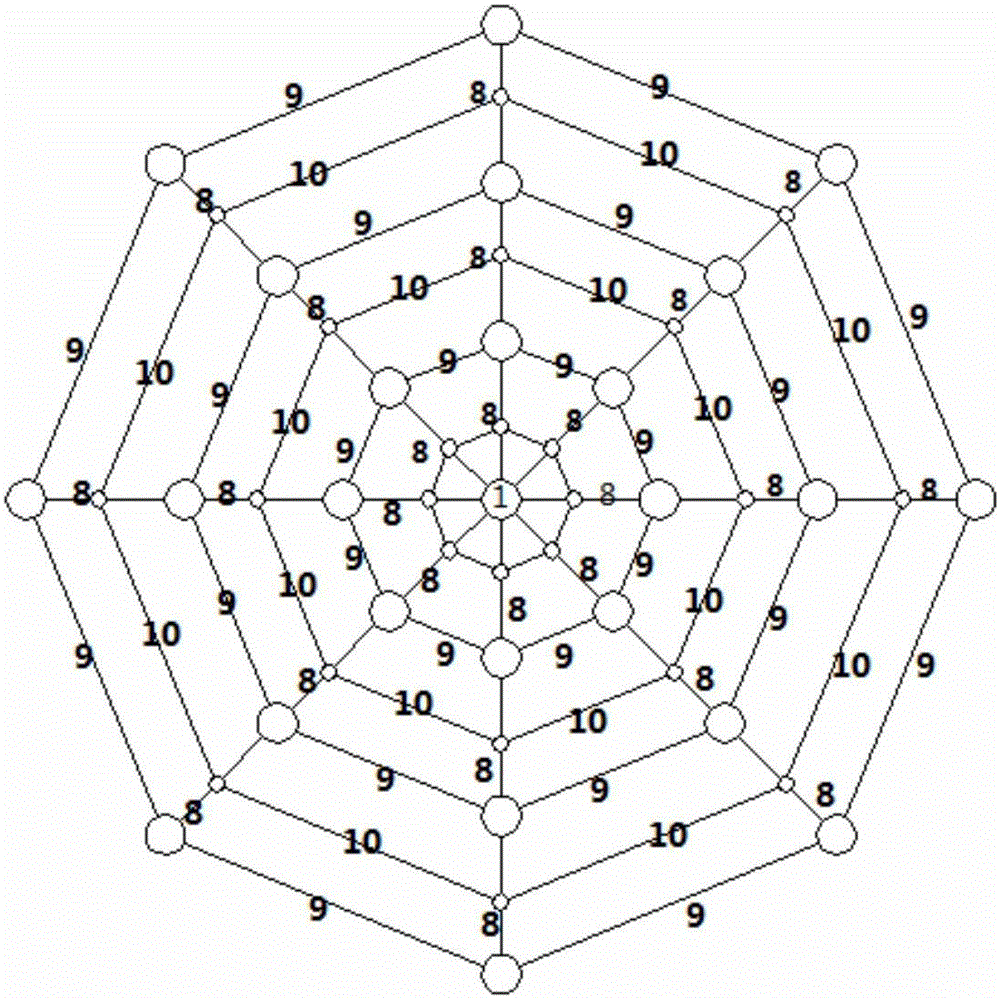

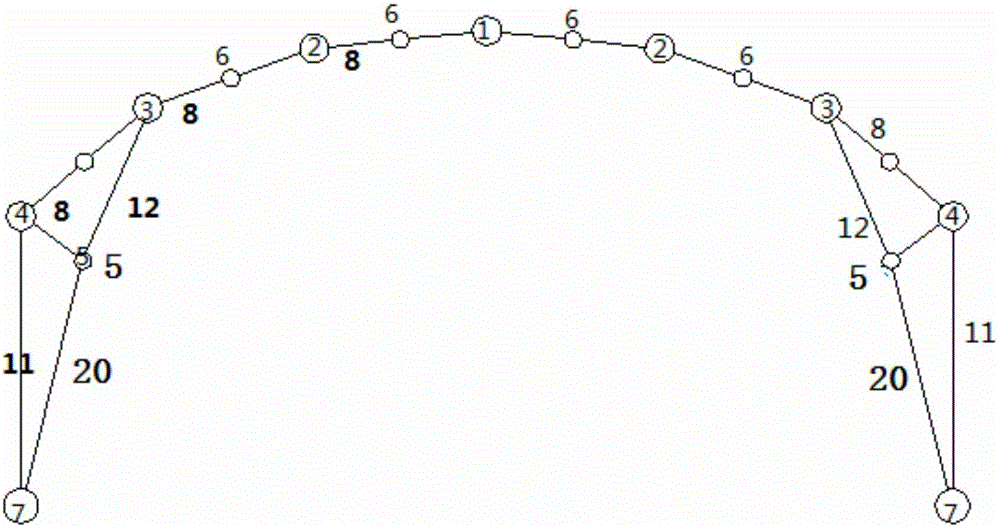

[0046] Such as figure 1 , Shown in 2 and 3, the bamboo rib ring spherical reticulated shell of the present invention includes an upper rib ring spherical bamboo mesh, a lower brace system, and a concrete foundation.

[0047]The upper rib ring spherical bamboo net includes a plurality of latitudinal ring members 13 formed by connecting latitudinal rods 9 end to end, a plurality of radial rods 8 , a plurality of steel nodes, a plurality of purlins 10 , and a plurality of purlin bolt nodes 6 . A plurality of latitudinal ring members 13 are concentrically arranged with the central steel node as the center of the circle, and the central steel node is sequentially connected to a plurality of latitudinal ring members 13 through a plurality of radial rods 8. The purlins 10 are connected to the rods 8 to form a purlin ring, the latitudinal rods 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com