Powerful high-speed electromagnetic valve

A solenoid valve and electromagnet technology, applied in the field of solenoid valves, can solve the problems that solenoid valves are difficult to meet technical requirements, and achieve the effects of improving fuel economy, low inductance, and large electromagnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is attached Figure 1 to Figure 5 To describe and illustrate the present invention in detail:

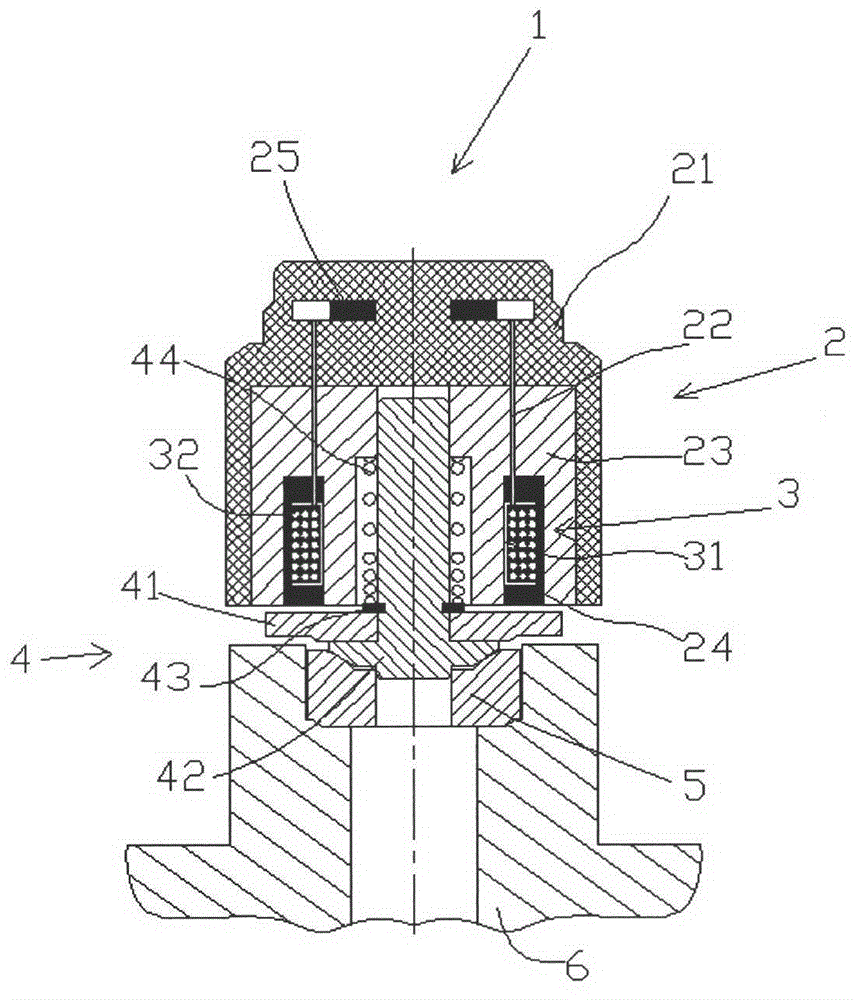

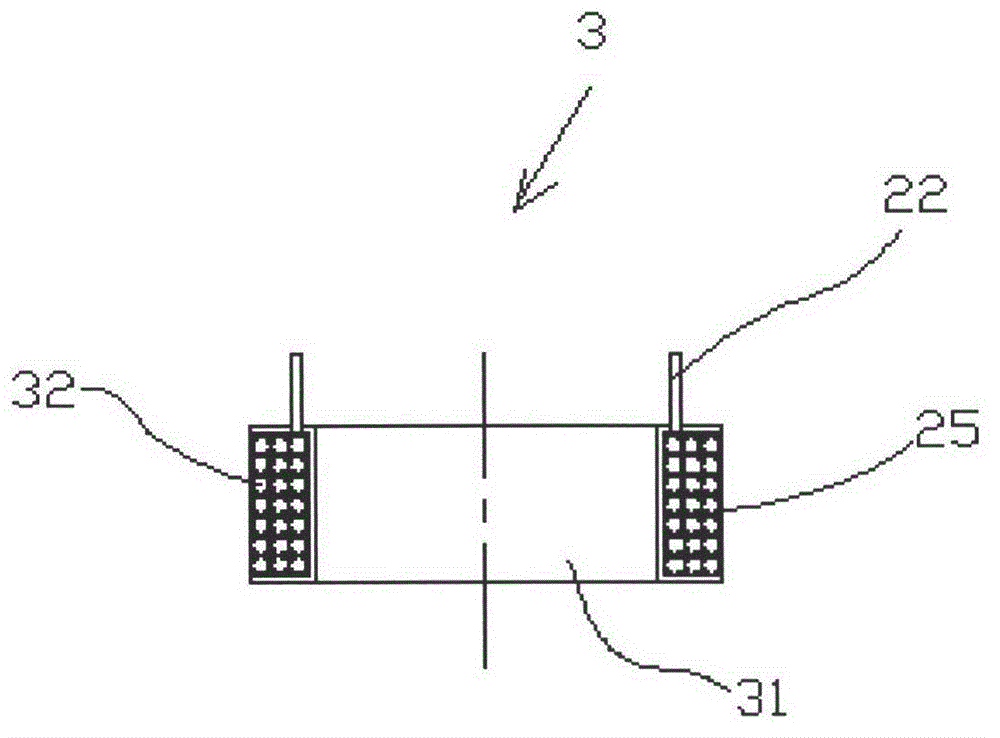

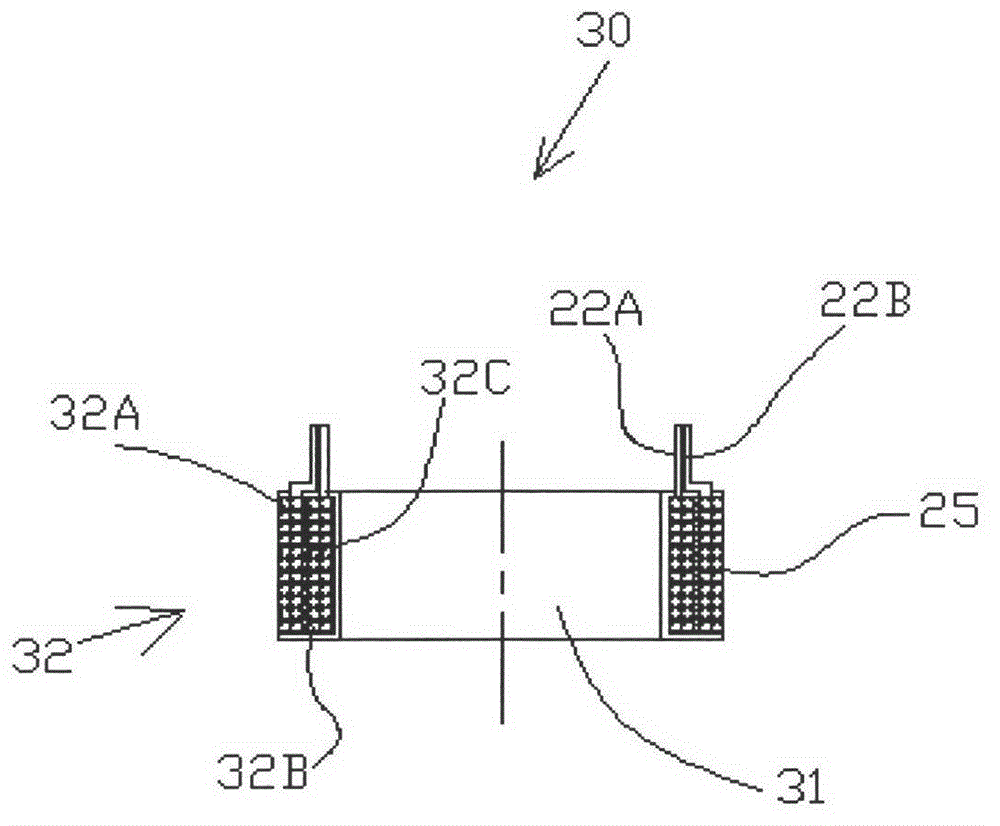

[0024] figure 1 It is a schematic structural diagram of a solenoid valve 1 in the prior art. The solenoid valve 1 is mainly composed of an electromagnet assembly 2 , an armature valve stem movement assembly 4 , a valve seat 5 , and a valve seat base 6 . The electromagnet assembly 2 is composed of an electromagnet casing 21, an iron core 23, an electromagnetic coil skeleton assembly 3, a copper terminal 22, an electrode 25, an electromagnetic coil sealing glue 24, and the like. The shell 21 of the electromagnet is made of non-magnetic metal aluminum-copper alloy or polymer material, and the iron core 23 is made of silicon steel laminations and soft magnetic materials (electrical pure iron, iron-silicon alloy, iron-phosphorus alloy, iron-cobalt alloy ) is processed; the electromagnetic coil skeleton assembly 3 is assembled and placed in the inner ring groove at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com