Durometer for measuring variable-temperature hardness of metal material

A metal material and hardness tester technology, applied in the direction of testing the hardness of materials, measuring devices, analyzing materials, etc., can solve problems such as the inability to accurately reflect the hardness level, unfavorable new materials, new technological progress, and limiting the temperature-changing mechanical properties of materials, etc. To achieve the effect of simple structure, long service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

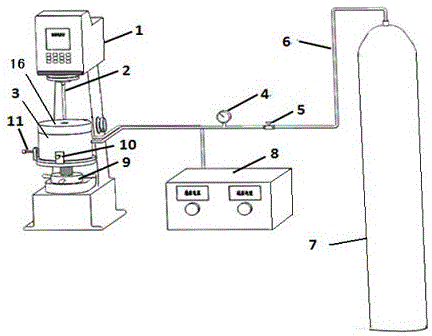

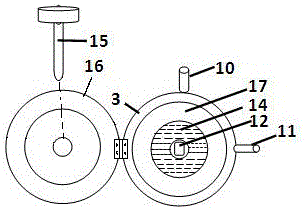

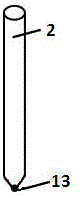

[0018] The present invention consists of a hardness tester main body 1, a hardness measuring pressure rod 2, a heating furnace body 3, a gas pressure gauge 4, an air flow switch valve 5, a gas pipeline 6, a protective atmosphere gas source 7, a temperature controller 8, a heating furnace lifting platform 9, The sample horizontal push rod 10, thermocouple 11, sample stage 12, hardness measuring indenter 13, embedded heating body 14, sealing plug 15, furnace body upper cover 16, and nano heat insulating material 17 are composed.

[0019] As shown in the figure, the overall structure of the present invention is that the hardness measuring pressure rod 2 is installed on the hardness tester main body 1, the hardness measuring pressure rod 2 is placed vertically, the heating furnace body 3 is located under the hardness measuring pressure rod 2, and the heating furnace body 3 is placed On the heating furnace lifting platform 9 , the protective atmosphere gas source 7 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com