High-low-temperature in situ XRD analyzing and testing method for lithium iron phosphate electrode material

A lithium iron phosphate and electrode material technology, applied in the field of nanomaterials and electrochemical in-situ analysis, can solve problems such as bad hidden dangers, and achieve the effect of optimizing low-temperature performance and improving low-temperature degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

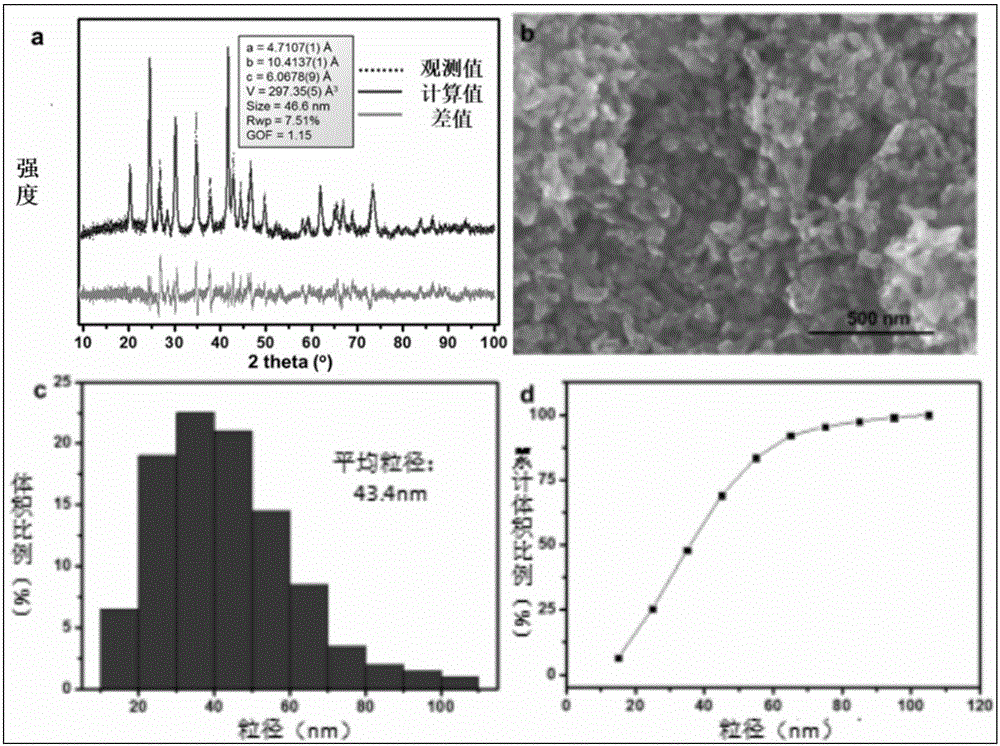

[0020] 1) Lithium carbonate, ferrous oxalate, ammonium dihydrogen phosphate, add an appropriate amount of acetylene black according to the stoichiometric ratio, and mill in a high-energy ball mill for 1 hour. The above materials are kept at 600°C for 4 hours in an argon atmosphere to obtain lithium iron phosphate;

[0021] 2) Through step 1) you can get figure 1 (a) XRD pattern and figure 1 (b) SEM topography; the obtained lithium iron phosphate electrode material, acetylene black, and PTFE are ground in a mass ratio of 6:3:1; the electrode material is obtained, and the in-situ battery is assembled, and the cycle performance (such as figure 2 ) and good rate performance;

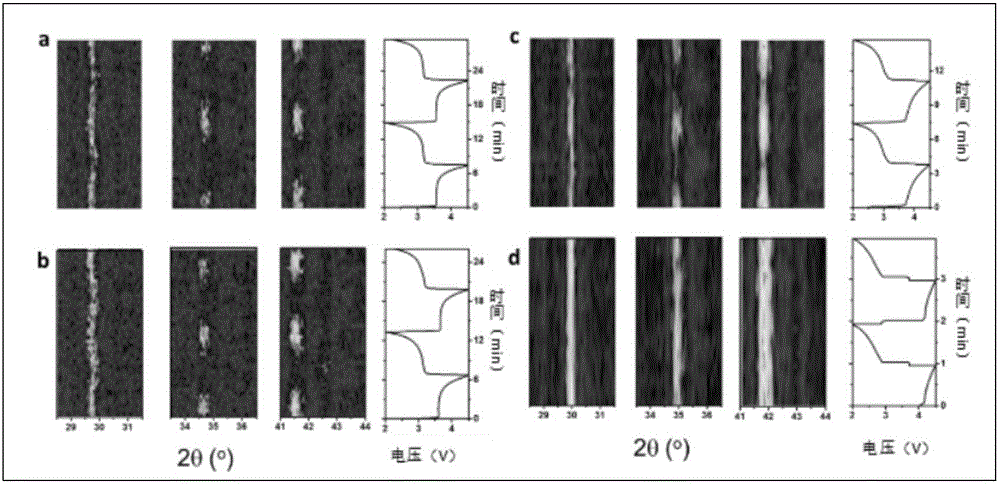

[0022] 3) The in-situ battery is tested with a high and low temperature test mold, and the change of the XRD peak of the material during the reaction process is observed at the same time. The specific steps are: use the X-ray light source of the general laboratory, set the in-situ test program to obtain a...

Embodiment 2

[0027] Constant current high temperature room temperature test

[0028] 1) Stir lithium nitrate, ferrous oxalate and citric acid in deionized water, add ammonium dihydrogen phosphate, add an appropriate amount of PEG (polyethylene glycol), stir for 6 hours to obtain a uniform solution, and dry at 80°C for 24 hours to obtain a powder. Grind the powder, and sinter the uniformly ground powder at 600°C under an argon atmosphere to obtain a lithium iron phosphate electrode material sample. figure 1 To obtain the XRD pattern of the sample;

[0029] 2) Mix the obtained lithium iron phosphate electrode material sample with acetylene black and PTFE to obtain an electrode sheet, further assemble the in-situ battery, and let it stand for 2 hours;

[0030] 3) Start and calibrate the height and position of the sample stage of the XRD equipment, so that the X-rays can accurately hit the lithium iron phosphate electrode material sample;

[0031] 4) Set the XRD equipment program, set the tu...

Embodiment 3

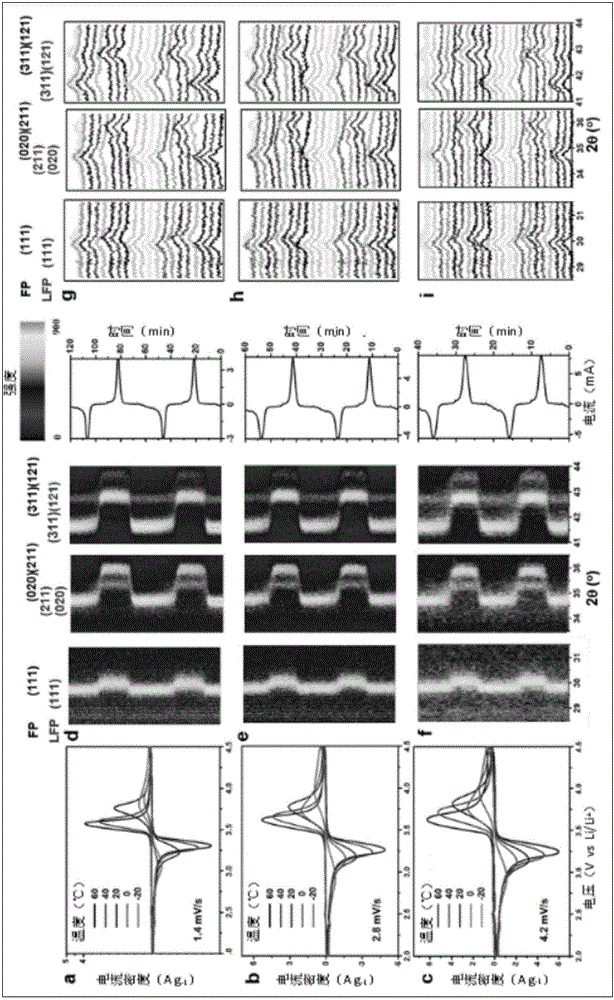

[0036] High temperature room temperature CV test

[0037] Step 1)-5) is the same as embodiment 2 step 1)-step 5);

[0038] 6) Start the electrochemical test program, use the Chenhua electrochemical workstation to test the open circuit voltage of the battery to obtain the open circuit voltage v1, set the scanning voltage range to 2.4-4.5V, the initial voltage v1, and the scanning rate to 1.38mV / s, 2.7mV / s, 4.2mV / s. for three different scan rates. Sweep three cycles separately. Start the test to get the in-situ CV test results, such as image 3 shown.

[0039] Follow the steps to complete the in-situ XRD test of the high temperature CV charge and discharge of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com