Concentrating cell radiating assembly, packaging method and application thereof

A technology of concentrating cells and heat dissipation components, applied in the field of solar power generation, can solve the problems of relatively high requirements for packaging materials, limited air contact area, and low heat dissipation effect, so as to achieve the best overall cost and life, avoid high current voltage breakdown, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

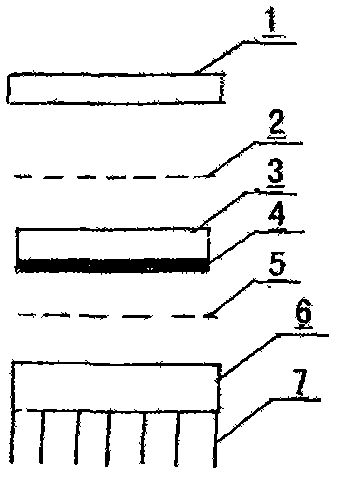

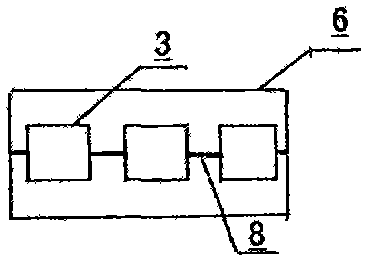

[0037] Packaging method for condensing cell cooling components of crystalline solar cells

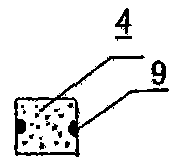

[0038] Prepare a thicker aluminum oxide film on the surface of the heat-conducting metal substrate and the outer surface of the heat-dissipating component of the concentrating cell by anodic oxidation film-making process;

[0039] Use heat-conducting glue to bond the conductive tape in the groove of the heat-conducting metal substrate. After curing, evenly coat a thin layer of conductive silver glue on the surface of both ends of the electrode of the crystalline solar cell, and coat the rest of the insulating heat-conducting glue; The conductive silver glue of the battery is bonded to the end point of the conductive tape of the heat-conducting metal substrate to form a connecting circuit, and the heat-dissipating component of the concentrating cell is placed in a thermostat at 180 degrees Celsius for half an hour to be bonded and cured and taken out;

[0040] Clean and air-dry the compo...

Embodiment 2

[0042] For the encapsulation method of the concentrating cell heat dissipation component of the thin film solar cell

[0043] Prepare a thicker aluminum oxide film on the surface of the heat-conducting metal substrate and the outer surface of the heat-dissipating component of the concentrating cell by anodic oxidation film-making process;

[0044] Thin-film solar cells and circuits are directly prepared on the heat-conducting metal substrate aluminum oxide film by the thin-film solar cell preparation process;

[0045] Clean and air-dry the components, and after confirming that there is no dirt on the surface, put them into the equipment and prepare a layer of transparent and insulating nano-alumina and nano-silicon oxide on the surface of the thin-film solar cell and the surface of the circuit using the PECVD coating in the film-making process;

[0046] Then press-bond the UV-filtering glass on the top of the heat-conducting metal substrate coated with waterproof glue and fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com