A kind of diamond brushed sheet and preparation method thereof

A technology of diamond and brushed sheet, which is applied in the field of diamond brushed sheet and its preparation, can solve the problems of fast wear, low processing accuracy and low processing efficiency, and achieve the effects of convenient use, improved processing efficiency and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

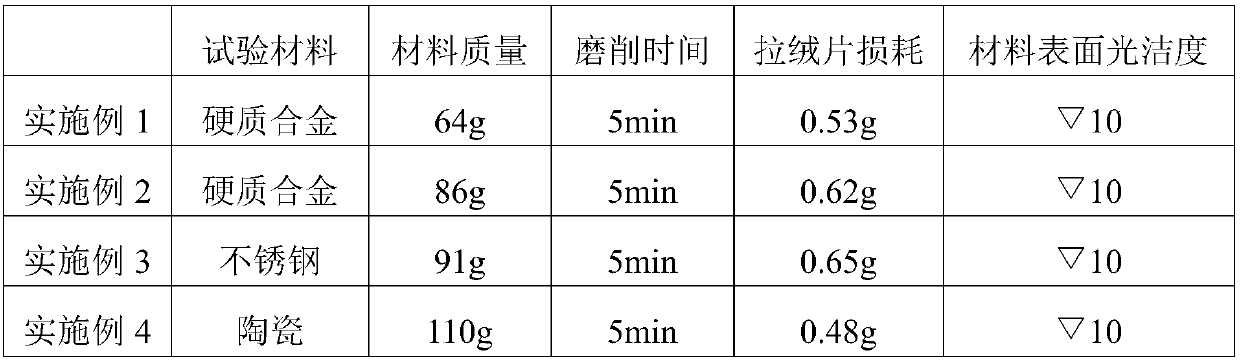

Examples

Embodiment 1

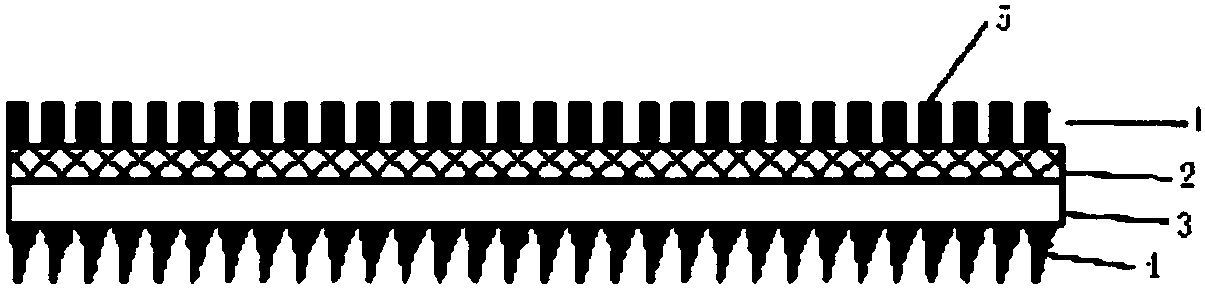

[0035] The schematic diagram of the structure of the diamond brushed sheet is shown in Figure 1, including a grinding layer 1, a substrate 2 and a cloth base 3, the grinding layer 1 is attached to the base body 2 by electroplating, the base body 2 is bonded to the front of the cloth base 3, and the back of the cloth base 3 is planted. There are fluff 4, and the grinding layer 1 is composed of nickel-diamond composite electroplating layers 5 evenly spaced. Its preparation method is as follows:

[0036] The 200-325 mesh wire mesh (substrate 2) is electroplated in the nickel-diamond electroplating solution to form a silver-white nickel-diamond composite electroplating layer 5, and the nickel-diamond composite electroplating layer 5 is evenly spaced to form the grinding layer 1. The layer is attached to a wire mesh (substrate 2), the content of diamond in abrasive layer 1 is 11 wt%.

[0037] After washing and drying, apply epoxy resin evenly on the front of the man-made fiber clo...

Embodiment 2

[0041] The 200-325 mesh wire mesh is electroplated in the nickel-diamond electroplating solution to form a silver-white nickel-diamond composite electroplating layer. The nickel-diamond composite electroplating layer is evenly spaced to form a grinding layer, and the grinding layer is attached to the wire mesh. The content of diamond in the grinding layer is 9wt%.

[0042] After washing and drying, apply epoxy resin evenly on the front of the man-made fiber cloth base, bond the non-plated surface of the wire mesh with the front of the cloth base, and then dry and cure in a curing kiln. The drying temperature is 80°C and the time is 1h, the curing temperature is 120°C, and the curing time is 2h.

[0043] Plant red fluff on the back of the cloth base to make a brushed cloth embryo.

[0044] It is punched out by a punching machine into a round brushed sheet with a diameter of 100 mm and a hole in the middle with a diameter of 16 mm.

Embodiment 3

[0046] The 200-325 mesh wire mesh is electroplated in the nickel-diamond electroplating solution to form a silver-white nickel-diamond composite electroplating layer. The nickel-diamond composite electroplating layer is evenly spaced to form a grinding layer, and the grinding layer is attached to the wire mesh. The content of diamond in the grinding layer is 10wt%.

[0047] After washing and drying, apply epoxy resin evenly on the front of the man-made fiber cloth base, bond the non-plated surface of the wire mesh with the front of the cloth base, and then dry and cure in a curing kiln. The drying temperature is 80°C and the time is 1h, the curing temperature is 120°C, and the curing time is 2h.

[0048] Plant green fluff on the back of the cloth base to make a brushed cloth embryo.

[0049] It is punched into an equilateral triangle brushed sheet with a side length of 80 mm through a punching machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com