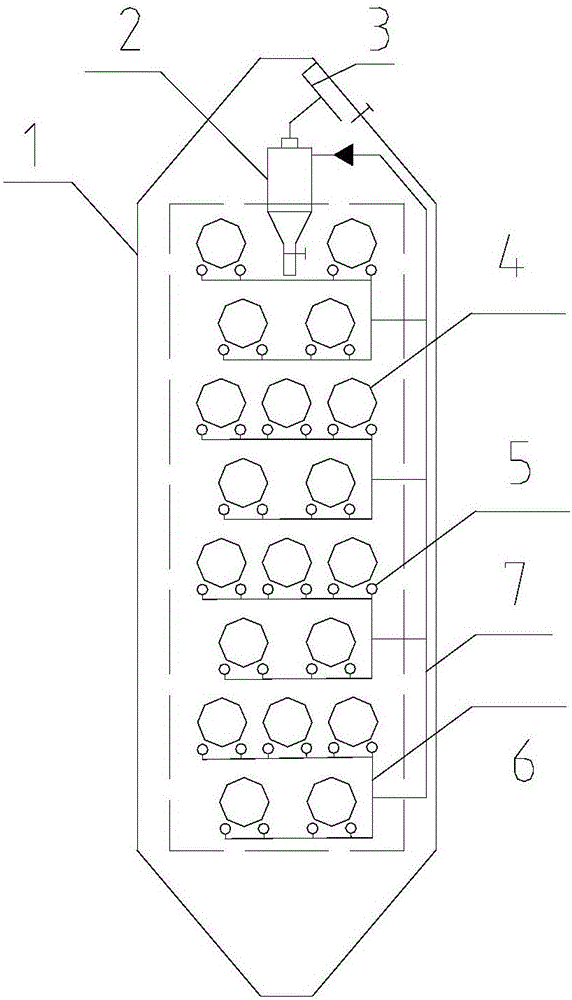

Quick coal pyrolysis reactor

A technology of pyrolysis reactor and reactor, which is applied in special forms of dry distillation, petroleum industry, coke oven, etc., can solve problems such as complex composition, high gas temperature, and irregular dust shape, so as to increase light components and reduce Effect of dust content and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

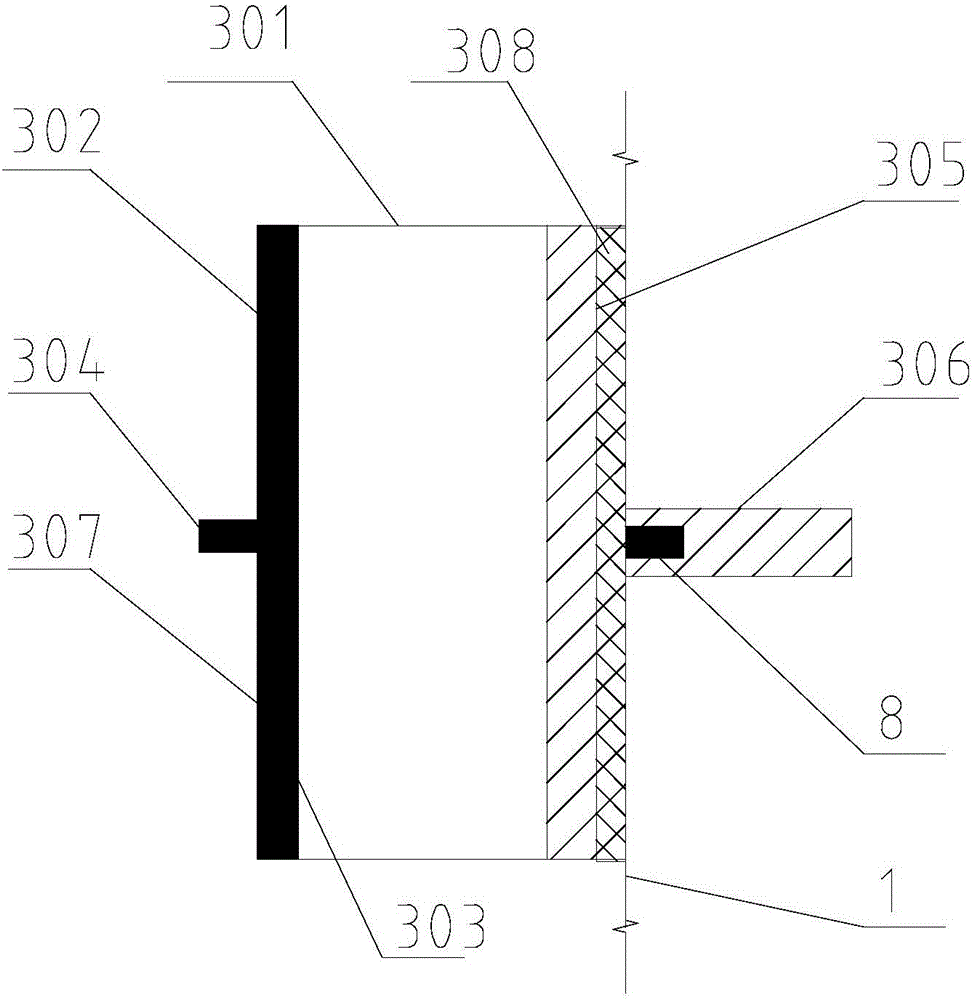

[0049] The raw coal is pulverized to less than 3mm, and enters the reactor body through the raw material inlet. Part of the raw coal enters the granular moving bed, and the moving speed of the raw coal in the granular bed is controlled by controlling the valve at the bottom of the moving bed, generally less than 0.5m / s, for example, 0.1, 0.2, 0.3m / s. The high-temperature pyrolysis oil gas is collected by the gas collection device, and passes through the cyclone separator and the particle moving bed, which effectively reduces the dust content in the pyrolysis oil gas, and at the same time reduces the temperature of the coal pyrolysis oil gas, and some (40-60%) heavy The tar condensation returns to the pyrolysis furnace along with the pyrolysis feedstock. The dust content of pyrolysis oil gas is reduced to 0.2g / Nm 3 , no particle moving bed dust content 5.5g / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com