Method for enriching germanium from lignite flue dust

A soot and lignite technology, applied in the field of non-ferrous and rare metal extraction, can solve the problems of unfavorable direct reduction, volatilization and enrichment, etc., and achieve the effect of reducing equipment scale, reducing acid consumption, and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

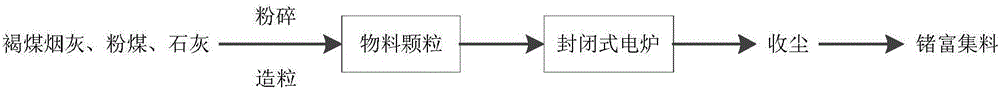

[0015] According to a typical embodiment of the present invention, a method for enriching germanium from lignite dust is provided. The method comprises the following steps: S1, mixing lignite dust with pulverized coal and lime, and then granulating to obtain material granules; S2, putting the material granules into a heating furnace, controlling the heating furnace to be a reducing atmosphere, and the temperature is 1200-1500°C , reduced and volatilized for 2 to 18 hours, and collected dust to obtain germanium-enriched material.

[0016] Among them, the main function of pulverized coal is to use the heat released by pulverized coal combustion and the carbon monoxide produced as reducing gas. By adjusting the proportion of pulverized coal, it can be controlled to a weak reducing atmosphere to avoid the reduction of germanium dioxide in germanium fume to metal. germanium. The addition of lime mainly plays the role of adjusting the slag type and reducing the slag temperature.

...

Embodiment 1

[0024] refer to figure 1 The process uses germanium-containing fumes as raw materials, and the main component is SiO 2 35%, Fe15%, Al 2 o 3 12%, CaO12%, Ge0.8%, mixed with pulverized coal and lime according to the mass ratio of 1:0.5:0.15, crushed and sieved, the particle size is controlled to 50 mesh, and then pelletized with a disc granulator to obtain the diameter 15mm balls are sent into the closed electric furnace, the temperature is controlled at 1200°C, and the temperature is maintained for 4 hours. During this period, the stirring of the molten pool is strengthened. The dust contains 5.1% Ge, the germanium enrichment ratio is 6 times, and the recovery rate is 92%.

Embodiment 2

[0026] Using germanium-containing fumes as raw materials, the main component is SiO 2 35%, Fe15%, Al 2 o 3 12%, CaO12%, Ge1%, mixed with pulverized coal and lime according to the mass ratio of 1:0.2:0.1, crushed and sieved, the particle size is controlled to 50 mesh, and then pelletized with a disc granulator to obtain a diameter of 15mm The small balls are sent into the closed electric furnace, the temperature is controlled at 1350 °C, and the temperature is maintained for 4 hours. During this period, the stirring of the molten pool is strengthened. The content of Ge is 4.1%, the enrichment ratio of germanium is 4.1 times, and the recovery rate is 90.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com