Prefabricated reinforcement concrete block T-shaped rib anti-buckling steel plate earthquake resistant wall

A technology of reinforced concrete and steel plate walls, which can be used in earthquake-proof, wall, building types, etc., can solve the problems of high transportation and installation requirements, complicated connections, etc., and achieve the effect of improving shear bearing capacity, clear functions, and reasonable stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

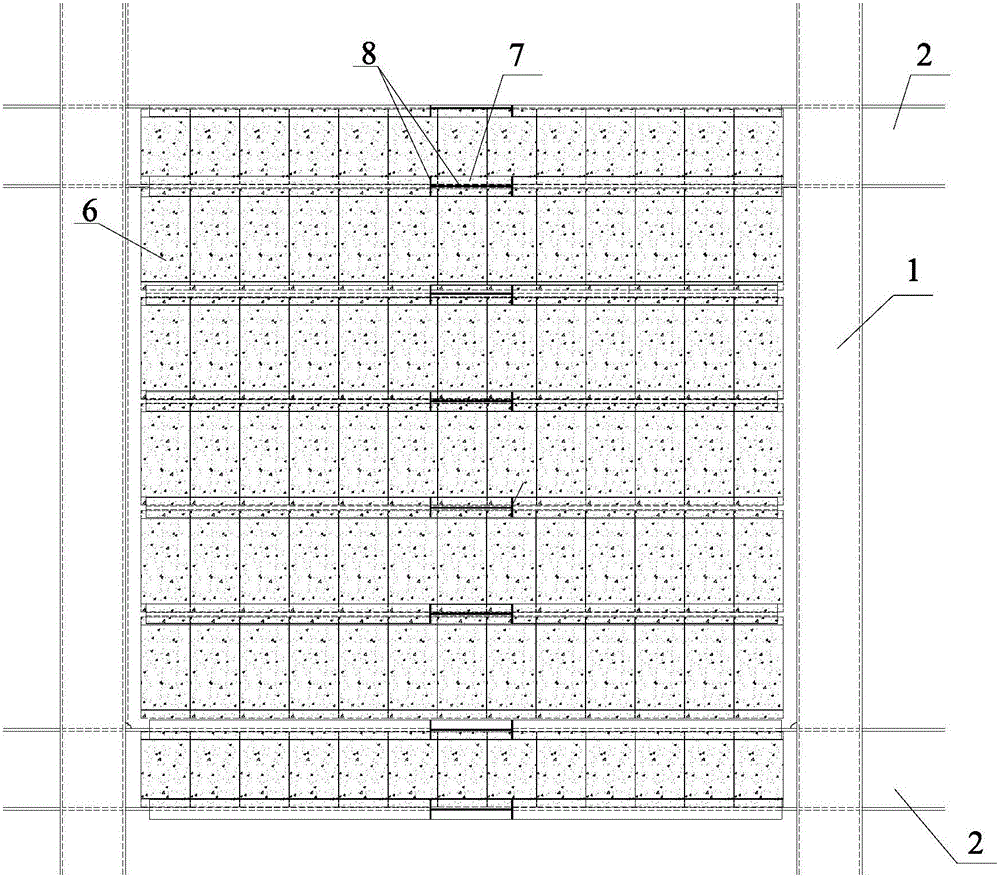

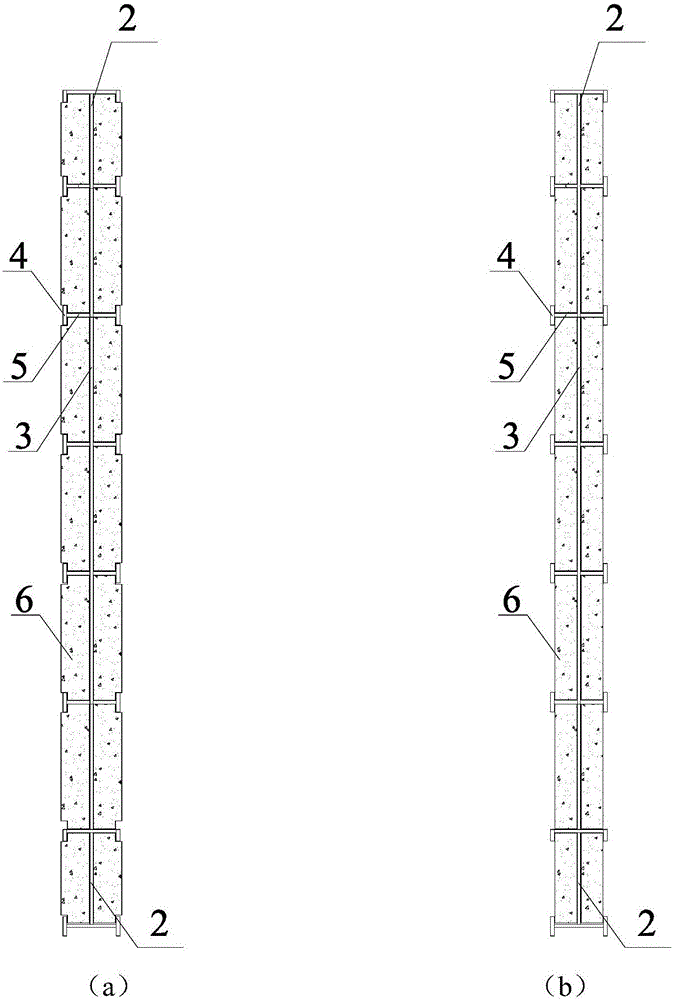

[0040] This embodiment includes steel plate wall 3, prefabricated reinforced concrete block 6, T-shaped ribs, steel column 1 and steel beam 2, steel plate wall 3 is placed in the frame formed by steel column 1 and steel beam 2, and steel plate wall 3 is surrounded by Steel beam 2 and steel column 1 are fixedly welded.

[0041] Such as figure 1 As shown, the steel plate shear wall bears the horizontal shear force, and the T-shaped ribs are fixed on the walls on both sides of the steel plate wall 3 at parallel intervals along the horizontal direction to prevent the overall buckling of the steel plate wall. The T-shaped rib flange 4 and the steel plate wall 3 parallel, the specific implementation of the T-shaped rib can be welded by the T-shaped rib flange 4 and the T-shaped rib web 5, one end of the T-shaped rib web 5 is welded with the T-shaped rib flange 4, and the other end is welded with the steel plate wall 3 Together, the T-shaped rib web 5 is perpendicular to the steel p...

Embodiment 2

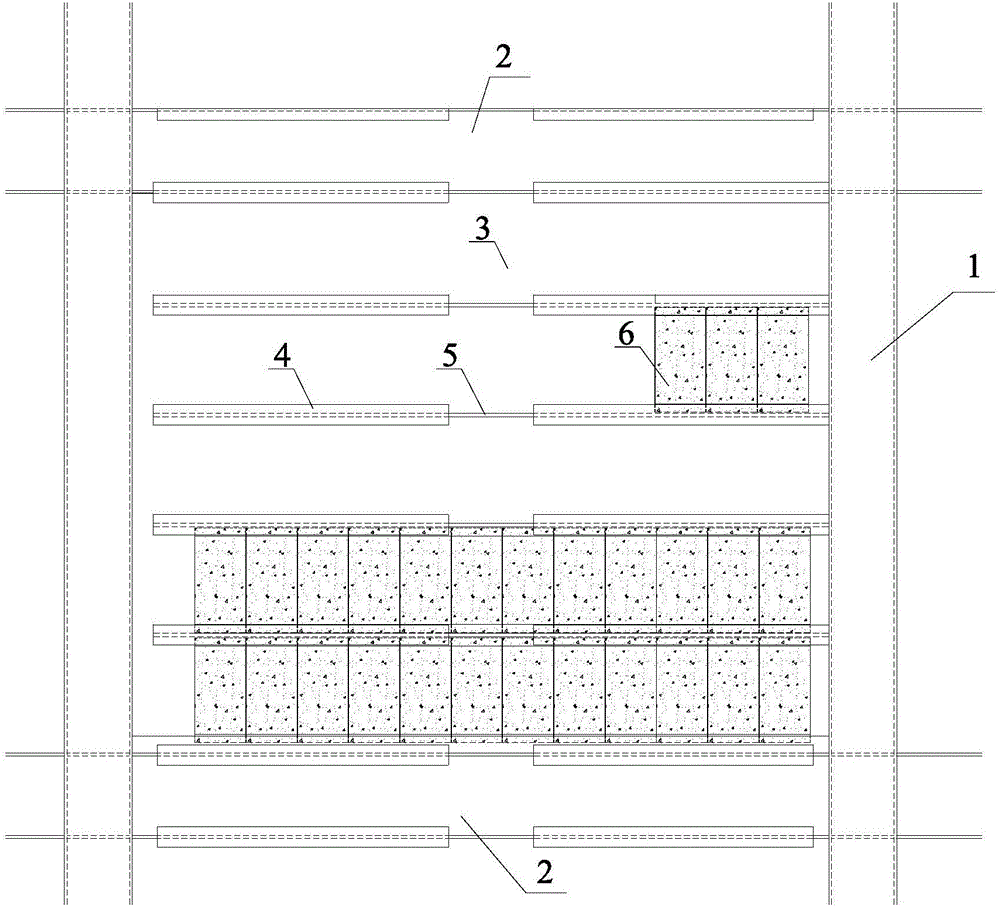

[0047] This embodiment includes steel plate wall 3, prefabricated reinforced concrete block 6, T-shaped ribs, steel column 1 and steel beam 2, steel plate wall 3 is placed in the frame formed by steel column 1 and steel beam 2, and steel plate wall 3 is surrounded by Steel beam 2 and steel column 1 are fixedly welded.

[0048] Such as Figure 4 As shown, the steel plate shear wall bears the horizontal shear force, and the T-shaped ribs are fixed on the walls on both sides of the steel plate wall 3 at parallel intervals along the vertical direction to prevent the overall buckling of the steel plate wall. The T-shaped rib flange 4 and the steel plate The walls 3 are parallel, and the specific implementation of the T-shaped rib can be welded by the T-shaped rib flange 4 and the T-shaped rib web 5, one end of the T-shaped rib web 5 is welded with the T-shaped rib flange 4, and the other end is welded with the steel plate wall 3 Together, the T-shaped rib web 5 is perpendicular to...

Embodiment 3

[0054] Such as figure 1 As shown, this embodiment includes a steel plate wall 3, prefabricated reinforced concrete block 6, T-shaped ribs, steel tube concrete columns and steel beams 2, the steel plate wall 3 is placed in the frame formed by the steel tube concrete columns and steel beams 2, and the steel plate wall 3 The surroundings are fixed and welded with steel beams 2 and concrete filled steel tube columns.

[0055] The steel plate shear wall bears the horizontal shear force. The steel plate wall 3 is divided into two or three pieces along the height. The T-shaped steel on both sides of the steel plate wall 3 is replaced by the same I-shaped steel. The upper and lower steel plate walls 3 are welded to the I-shaped steel. . The steel plate wall 3 and the web of the steel girder 2 are connected to form the same steel plate, and the flange of the steel girder 2 is welded on the steel plate.

[0056] The T-shaped ribs are fixed on the walls on both sides of the steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com