A Gaas-based light-emitting diode and its manufacturing method

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as poor ESD performance and affect crystal quality, and achieve the effect of improving anti-ESD performance and solving poor ESD performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

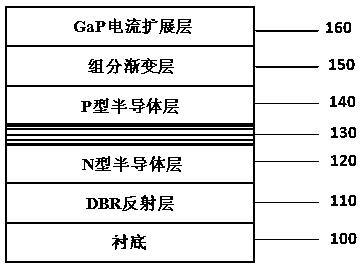

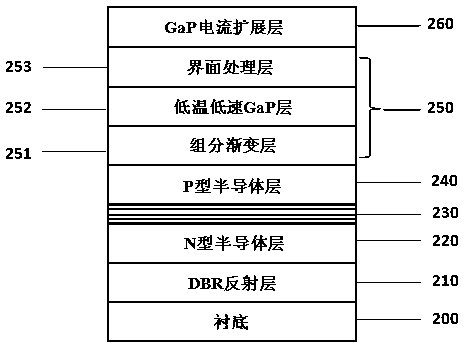

[0048] Such as figure 2 As shown, this embodiment provides a method for manufacturing a GaAs-based light-emitting diode, including the following process steps: using metal organic chemical vapor deposition (MOCVD) to epitaxially grow a DBR reflective layer 210, an N-type semiconductor layer 220, Quantum well light-emitting layer 230, P-type semiconductor layer 240, transition layer 250 and GaP current spreading layer 260, wherein transition layer 250 includes composition gradient layer 251, low temperature and low speed GaP layer 252, interface treatment layer 253, GaP current spreading layer 260 uses same growth temperature.

[0049] The manufacturing method of the GaAs-based light-emitting diode described in the present invention uses high-purity hydrogen (H2) as the carrier gas, trimethylgallium (TMGa), trimethylaluminum (TMAl), trimethylindium (TMIn), arsine (AsH3) and phosphine (PH3) are used as Ga, Al, In, As, and P sources respectively, and silane (Si2H6) and dimagnes...

Embodiment 2

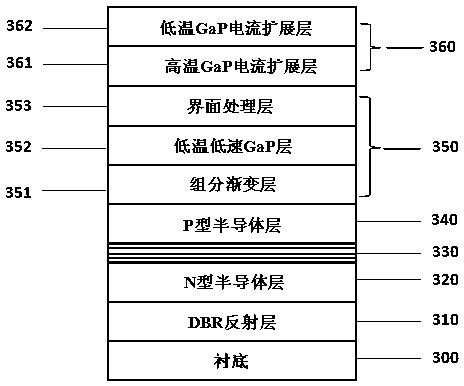

[0062] This embodiment is different from Embodiment 1 in that: the GaP current spreading layer is prepared by high temperature first and then low temperature. After the interface treatment layer is grown, the temperature is raised abruptly to grow a layer of high-temperature GaP, and then the temperature is suddenly lowered to the required growth temperature of the GaP current spreading layer for growth.

[0063] Such as image 3 with 4 As shown, a DBR reflective layer 310, an N-type semiconductor layer 320, a quantum well light-emitting layer 330, a P-type semiconductor layer 340, a transition layer 350, and a GaP current spreading layer are epitaxially grown sequentially on a substrate 300 by metal organic chemical vapor deposition (MOCVD). Layer 360. The transition layer 350 includes a graded composition layer 351 , a low temperature and low velocity GaP layer 352 , and an interface treatment layer 353 . The GaP current spreading layer includes a high temperature GaP cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com