Method of utilizing acidizing method to treat carbon nano tube to prepare carbon nano tube fiber

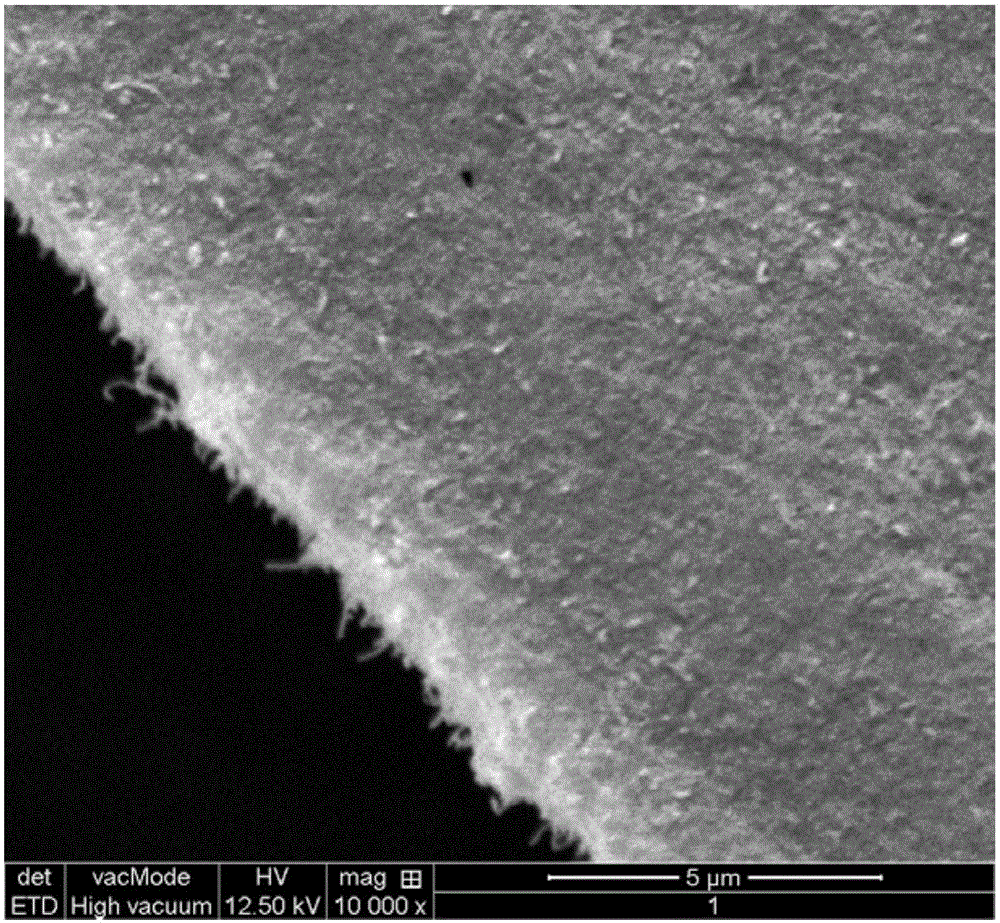

A technology of carbon nanotube fibers and carbon nanotubes, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, to achieve the effects of low cost, simple operation steps, good mechanical properties and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) First measure 10mL of nitric acid, then measure 30mL of concentrated sulfuric acid, slowly pour it into the flask filled with concentrated nitric acid, and keep stirring during the period.

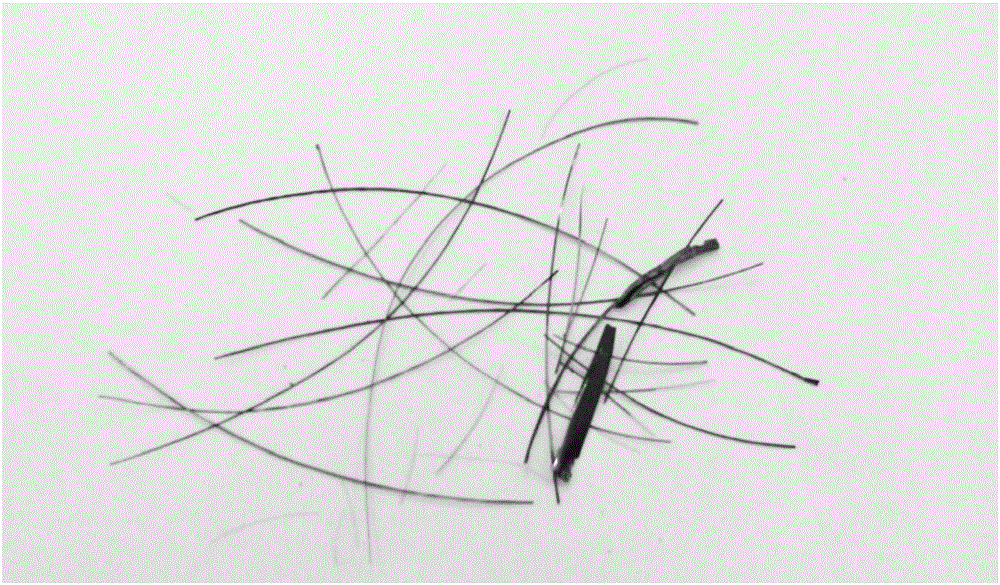

[0030] (2) Weigh 0.2 g of carbon nanotubes and pour them into the flask filled with the mixed acid in the step (1), place the flask in an ultrasonic cleaner for ultrasonic oscillation for 10 minutes, and shake it continuously during this period.

[0031] (3) Transfer the round-bottomed flask in the step (2) to a magnetic stirrer in a 90° C. oil bath, connect to a cooling reflux device, and cool and reflux for 2 hours under stirring.

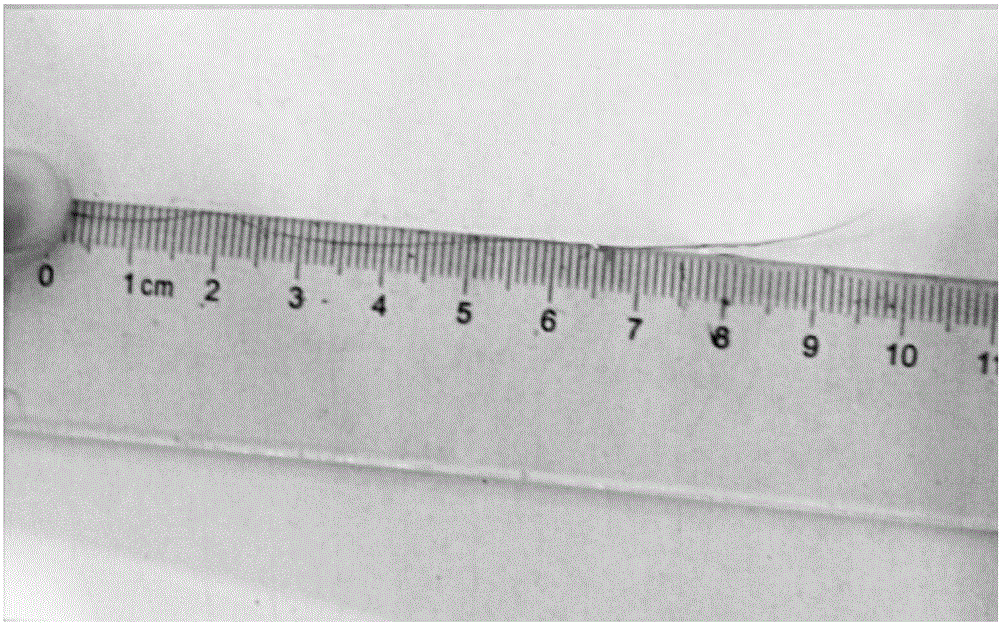

[0032] (4) After the oxidation treatment is finished, the solution in the step (3) is cooled to room temperature, and the solution is slowly poured into a beaker filled with distilled water, and kept stirring. Afterwards, filter with a sand core filter and use a microporous membrane with a pore size of 0.2 μm. After the mixed acid is pumped out, ri...

Embodiment 2

[0036] (1) First measure 10mL of nitric acid, then measure 30mL of concentrated sulfuric acid, slowly pour it into the flask filled with concentrated nitric acid, and keep stirring during the period.

[0037] (2) Accurately weigh 0.500 g of carbon nanotubes and pour them into the flask filled with the mixed acid in the step (1), place the flask in an ultrasonic cleaner and vibrate ultrasonically for 20 minutes, and shake it continuously during this period.

[0038] (3) Transfer the round-bottomed flask in the step (2) to a magnetic stirrer in an oil bath at 90° C., connect to a cooling reflux device, and cool and reflux for 3 hours under stirring.

[0039] (4) After the oxidation treatment is finished, the solution in the step (3) is cooled to room temperature, and the solution is slowly poured into a beaker filled with distilled water, and kept stirring. Afterwards, filter with a sand core filter and use a microporous membrane with a pore size of 0.2 μm. After the mixed acid ...

Embodiment 3

[0044] (1) First measure 5mL of nitric acid, then measure 15mL of concentrated sulfuric acid, slowly pour it into a flask filled with concentrated nitric acid, and keep stirring during this period.

[0045] (2) Accurately weigh 0.250 g of carbon nanotubes and pour them into the flask filled with the mixed acid in the step (1), place the flask in an ultrasonic cleaner and vibrate ultrasonically for 10 minutes, and shake it continuously during this period.

[0046] (3) Transfer the round-bottomed flask in the step (2) to a magnetic stirrer in an oil bath at 130° C., connect to a cooling reflux device, and cool and reflux for 2 h under stirring.

[0047] (4) After the oxidation treatment is finished, the solution in the step (3) is cooled to room temperature, and the solution is slowly poured into a beaker filled with distilled water, and kept stirring. Afterwards, filter with a sand core filter and use a microporous membrane with a pore size of 0.2 μm. After the mixed acid is pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com