Rock debris drying treatment and slurry purification system

A technology for mud purification and drying treatment, which is applied in the fields of sludge treatment, dewatering/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc. Standard treatment, difficulty in transporting cuttings, etc., to achieve the effect of small footprint, high use efficiency, and saving drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

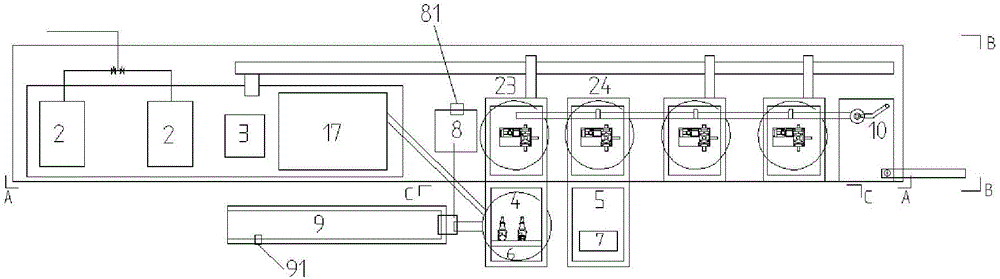

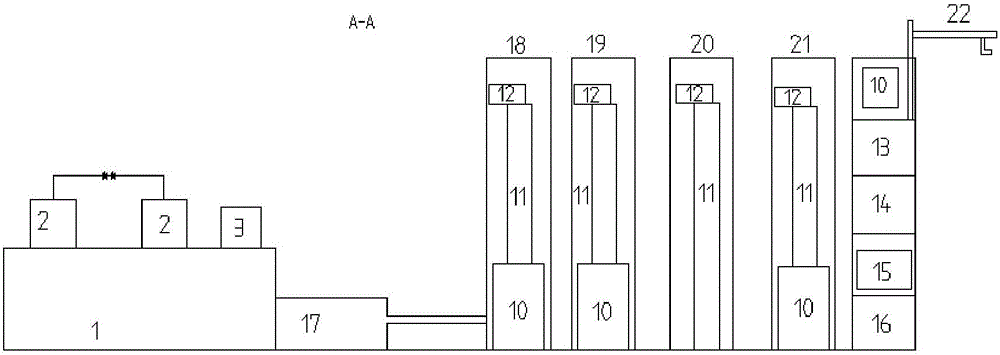

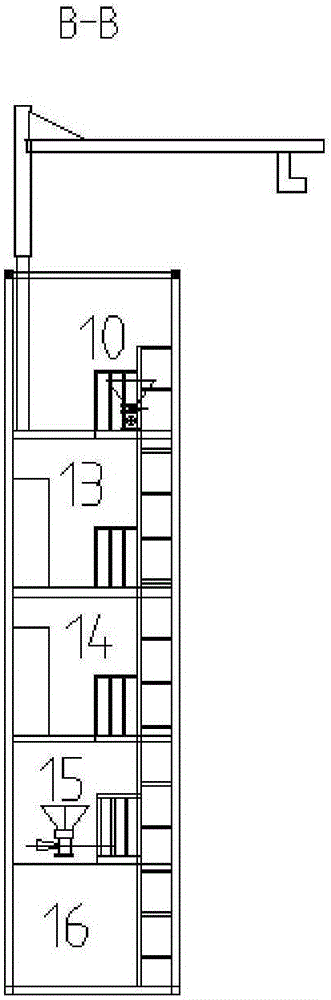

[0086] Such as Figure 1-4 As shown, the cuttings drying treatment mud purification system provided by this embodiment includes a primary treatment mud tank, a cuttings pump, a sand removal and mud removal integrated machine, a cuttings tank, a dryer and an air heater;

[0087] The cuttings pump is connected to the primary treatment mud tank, the primary treatment mud tank is connected to the cuttings tank through the integrated desanding and desilting machine, the cuttings tank is connected to the dryer, the dryer is connected to the air heater, and the air heater is connected to the exhaust pipe of the diesel engine;

[0088] The mud returned from the wellhead is transported to the primary treatment mud tank through the cuttings pump. After the primary treatment is carried out in the primary treatment mud tank, the mud is transferred to the cuttings tank through the integrated desanding and silting machine, and then sent from the cuttings tank to the dryer At the same time, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com