Electrostatic self-assembly method for preparing halloysite-white carbon black hybrid filler

A technology of electrostatic self-assembly and white carbon black, which is applied in the field of preparation of new hybrid materials, achieves the effect of simple molding process, high specific surface area, and large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

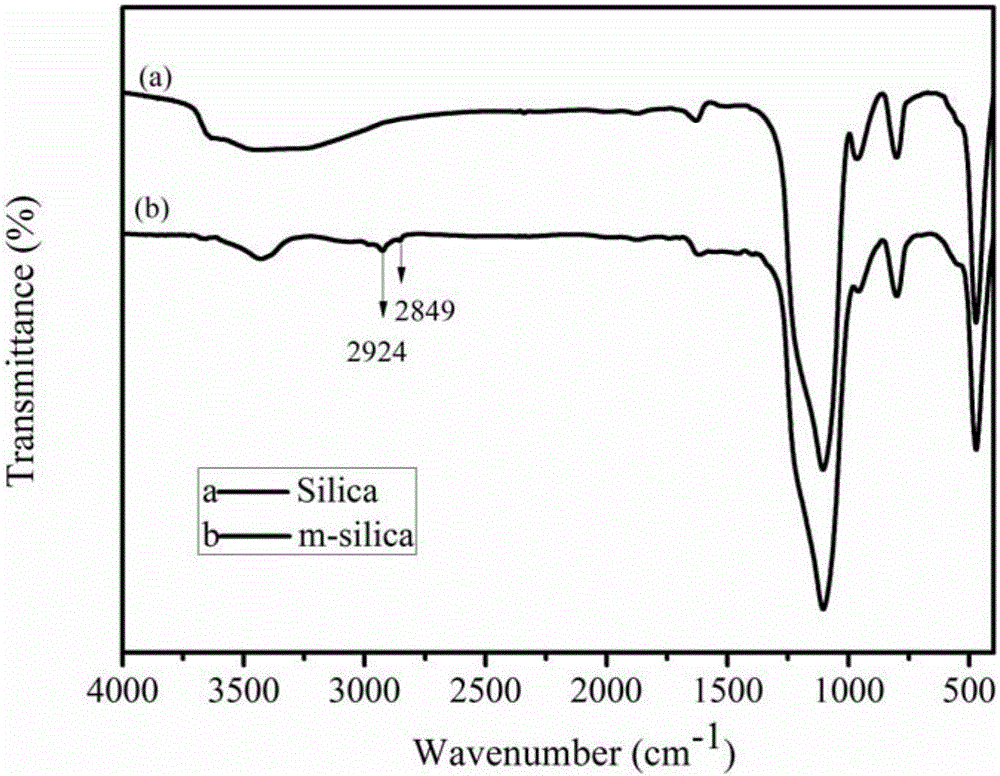

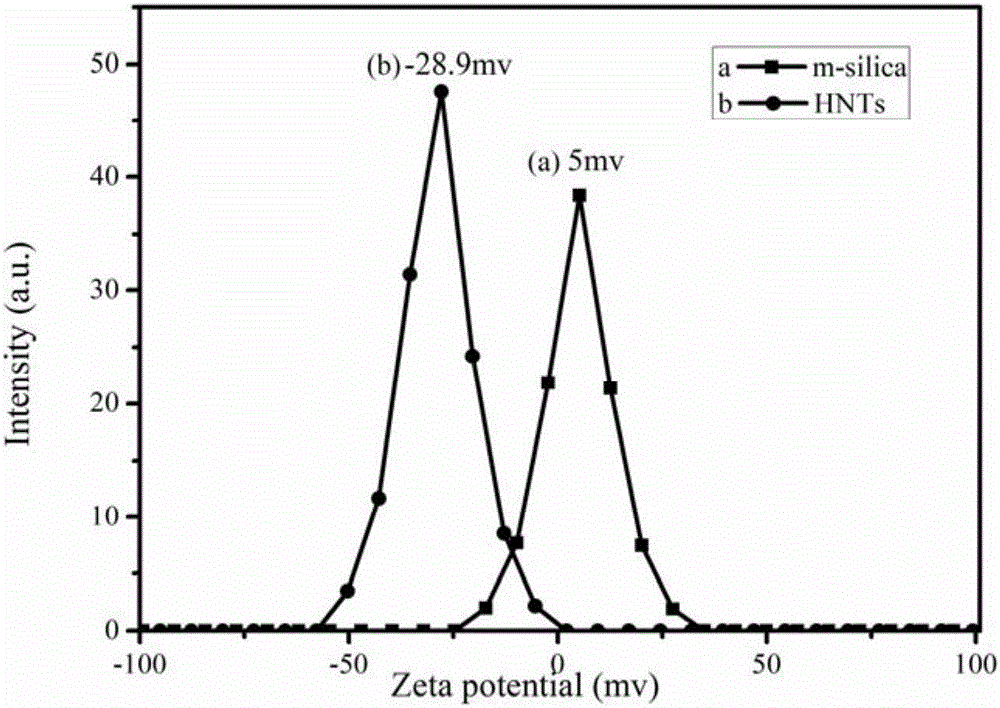

[0033] In a 250ml beaker, add a mixture of 100ml absolute ethanol, 5ml deionized water and 4.5g of 25wt% ammonia water, stir for 0.5 hour, then dropwise add 4.5g of tetraethyl orthosilicate to the mixture, after the dropwise addition, Stir for 12 hours to obtain white carbon black, then wash and dry the prepared white carbon black with water, take 3g and disperse it in 100ml of ethanol, add 1g of γ-aminopropyltriethoxysilane, and stir and react at 60°C for 10 hours , the product was centrifuged and washed three times with ethanol, and dried in a vacuum oven at 80°C to obtain modified white carbon black. figure 1 It is the infrared spectrogram of silica and modified silica, which shows that at 2924cm -1 and 2849cm -1 A distinct CH is generated at 2 Vibration peak, which indicates that the silane coupling agent has been successfully grafted to the surface of silica. figure 2 It is the Zeta potential diagram of modified silica and halloysite nanotubes. It can be seen from the...

Embodiment 2

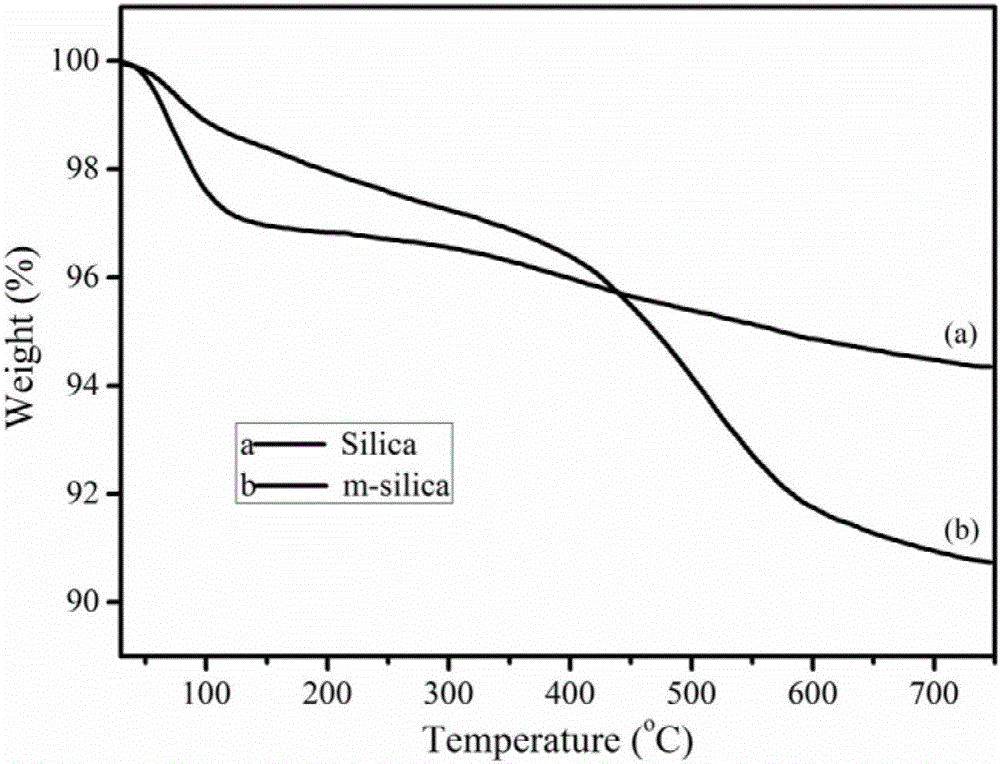

[0035] Disperse 10g of industrial-grade precipitated silica into 150ml of absolute ethanol, add 2g of γ-aminopropyltrimethoxysilane, react at 70°C for 10h, centrifuge the obtained modified silica, and wash with absolute ethanol Washed 3 times to obtain modified silica. image 3 is a thermogravimetric graph of silica and modified silica, and the thermogravimetric data of this graph shows that the grafting rate of the silane coupling agent is 3.6%. Get 2g of modified silicon dioxide and disperse it into 100ml deionized water. In addition, prepare 100ml concentration of 30wt% halloysite nanotube water dispersion, then add the modified silicon dioxide dispersion to the halloysite nanotube In the dispersion liquid, let it stand for 1h to obtain a hybrid filler, such as Figure 4 It can be seen from the figure that the halloysite surface is covered by a layer of nano-protrusions of silica, forming a unique structure, and the halloysite tubes and silica particles do not undergo self...

Embodiment 3

[0037] Disperse 5g of halloysite nanotubes in 100ml of 95% ethanol solution, add 1g of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, and react at 70°C for 12 hours, Centrifugal washing three times, adjusting the pH value to 7, and then drying in a vacuum oven at 80°C for 10 hours to obtain modified halloysite nanotubes; Figure 5 It is the infrared spectrum of halloysite and modified halloysite. It can be seen from the figure that the coupling agent is successfully grafted to the surface of the nanotube. Take 3g of modified halloysite nanotubes and disperse them into 100ml of deionized water. At the same time, the same quality of white carbon black is also dispersed into 100ml of deionized water, ultrasonically disperse for 30min, and then drop the modified halloysite nanotube solution Add it to the dispersion of silica and let it stand for 2 hours. The positively charged halloysite nanotubes and the negatively charged precipitation silica will settle by electrostatic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com