Preparation method of phase change material with palm oil as raw material

A technology of phase change material and palm oil, which is applied in the field of preparation of phase change material, can solve the problems of less practical application and popularization of phase change material, and achieves low expansion and shrinkage, good compatibility, and less supercooling and superheating phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

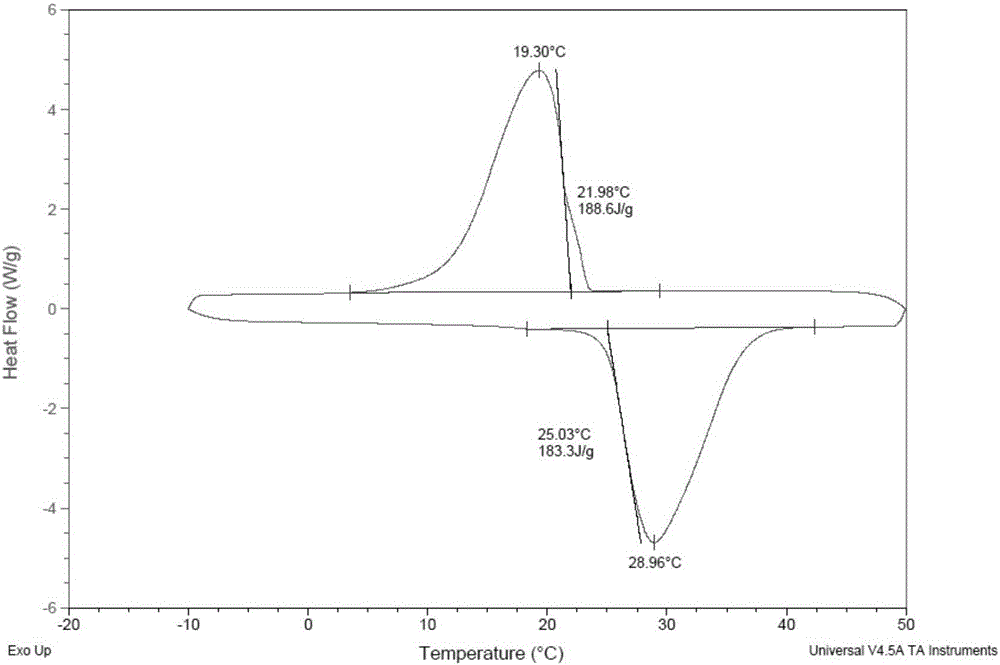

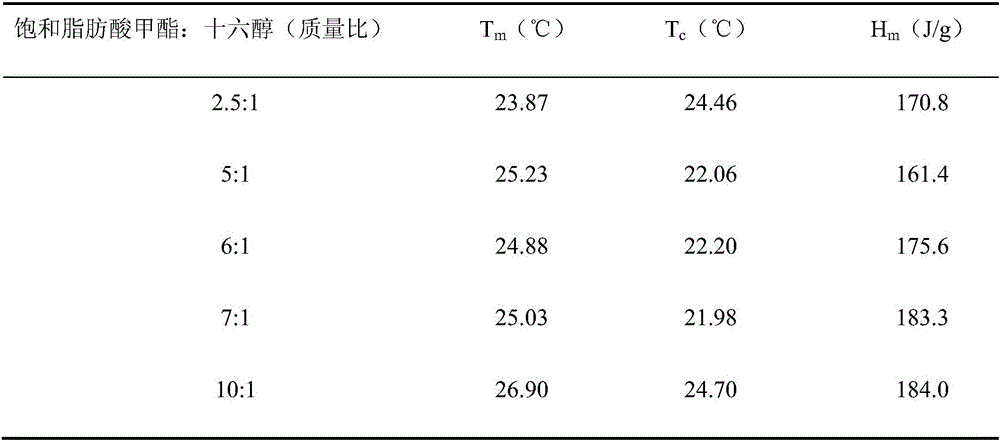

Examples

preparation example Construction

[0020] A kind of preparation method of the phase-change material that takes palm oil as raw material, comprises the steps:

[0021] (1) Preparation of refined methyl ester: Add palm oil and methanol with a molar ratio of 1:2 to 1:5 in a reaction vessel, stir and heat to 50-75°C and add catalyst sodium methoxide to a final concentration of 0.6% by mass , after reacting for 5 to 15 minutes, take the methyl ester phase for the second transesterification reaction, add palm oil and methanol with a molar ratio of 1:1 to 1:5, and add the catalyst sodium methoxide at 50 to 75°C to a final concentration of mass percent 0.2-0.4%, after reacting for 15-30 minutes, add phosphoric acid solution to neutralize until neutral, stir, take the methyl ester phase, wash it, dry it, and obtain the refined methyl ester;

[0022] (2) Preparation of saturated fatty acid methyl ester: add urea and ethanol with a mass percentage of 95% in the reaction vessel, the mass ratio of urea and ethanol is 1:2 to...

Embodiment 1

[0026] A kind of preparation method of the phase-change material that takes palm oil as raw material, comprises the steps:

[0027] (1) Preparation of refined methyl ester: Add palm oil and methanol with a molar ratio of 1:2 in a three-necked flask, stir (100r / min) and heat to 50°C, add catalyst sodium methylate to a final concentration of 0.6% by mass, After reacting for 5 minutes, take the methyl ester phase for the second transesterification reaction, add palm oil and methanol at a molar ratio of 1:1, stir (100r / min), and add catalyst sodium methoxide at 50°C to a final concentration of 0.2% by mass , after reacting for 15 minutes, add phosphoric acid solution to neutralize to neutrality, stir, take the methyl ester phase, wash it, dry it, and obtain the refined methyl ester;

[0028] (2) Preparation of saturated fatty acid methyl ester: use urea inclusion separation method to separate refined methyl ester, add urea and 95% ethanol in a three-necked flask, the mass ratio of...

Embodiment 2

[0031] A kind of preparation method of the phase-change material that takes palm oil as raw material, comprises the steps:

[0032](1) Preparation of refined methyl ester: Add palm oil and methanol with a molar ratio of 1:3.5 in a three-necked flask, stir (100r / min), add catalyst sodium methylate to a final concentration of 0.6% by mass at 65°C, and react After 10 minutes, take the methyl ester phase for the second transesterification reaction, add palm oil and methanol with a molar ratio of 1:2, stir (100r / min), add the catalyst sodium methoxide at 65°C to a final concentration of 0.3% by mass, After reacting for 25 minutes, add phosphoric acid solution to neutralize until neutral, stir slowly for 5 minutes, remove the methyl ester phase, remove excess methanol, wash with saturated saline, dry over anhydrous sodium sulfate, and obtain the refined methyl ester;

[0033] (2) Preparation of saturated fatty acid methyl ester: use urea inclusion separation method to separate refin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com