Preparation for bamboo fiber and polyaniline composite phase-change energy storage material

A technology of composite phase change and energy storage materials, applied in the field of new material research and development, can solve the problems of high risk factor, low thermal conductivity, volatile, etc., and achieve the effects of high latent heat of fusion, large specific surface area, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

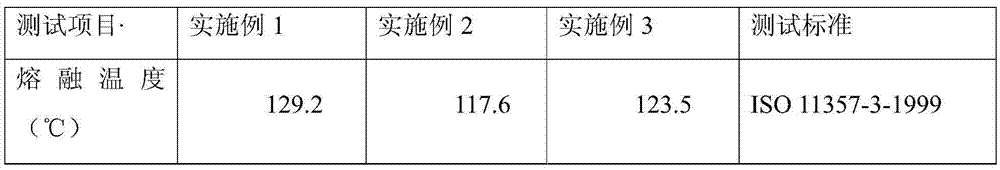

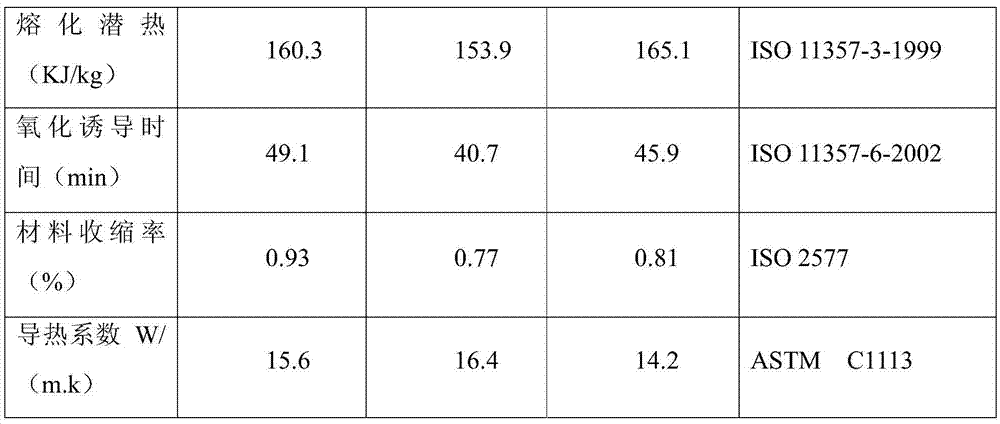

Embodiment 1

[0033] The composite phase change energy storage material of this embodiment, its preparation raw material contains the following components by weight: 80 weight parts of bamboo fiber; 20 weight parts of calcium chloride; 50 weight parts of sodium carbonate; 30 weight parts of ammonia water; 30 weight parts of ascorbic acid 30 parts by weight of hydrochloric acid; 40 parts by weight of aniline; 30 parts by weight of ammonium persulfate.

[0034] Preparation method: add 80 parts by weight of pulpy bamboo fiber to 20 parts by weight of calcium chloride, stir and ultrasonically disperse for 30 minutes to form a calcium chloride-bamboo fiber mixed solution; add 50 parts by weight of sodium carbonate to the mixed solution, stir ultrasonically for 30 minutes, Sodium and calcium chloride take place precipitation reaction, form bamboo fiber-calcium carbonate precipitation mixed solution, add ammoniacal liquor 30 weight parts in its mixed solution, make mixed solution be alkaline, and a...

Embodiment 2

[0036] The composite phase change energy storage material of this embodiment, its preparation raw material contains the following components by weight: 30 weight parts of bamboo fiber; 10 weight parts of magnesium chloride; 20 weight parts of ammonium bicarbonate; 10 weight parts of sodium hydroxide; 10 parts by weight of hydrochloric acid; 10 parts by weight of aniline; 10 parts by weight of ammonium persulfate.

[0037] Preparation method: add 30 parts by weight of pulpy bamboo fiber to 10 parts by mass of magnesium chloride, stir and ultrasonically disperse for 30 minutes to form a magnesium chloride-bamboo fiber mixed solution; add 20 parts by mass of ammonium bicarbonate to the mixed solution, and stir ultrasonically for 30 minutes Magnesium chloride, a precipitation reaction occurs, forming a bamboo fiber-magnesium carbonate precipitation mixed solution, adding 10 parts by weight of sodium hydroxide in its mixed solution, making the mixed solution alkaline, and adding 10 ...

Embodiment 3

[0039] The composite phase change energy storage material of this embodiment, its preparation raw material contains the following components by weight: 50 weight parts of bamboo fiber; 15 weight parts of barium chloride; 30 weight parts of potassium carbonate; 20 weight parts of potassium hydroxide; 20 parts by weight; 20 parts by weight of sulfuric acid; 20 parts by weight of aniline; 20 parts by weight of ammonium persulfate.

[0040] Preparation method: Add 50 parts by weight of pulpy bamboo fiber to 15 parts by weight of barium chloride, stir and disperse with ultrasonic for 35 minutes to form a barium chloride-bamboo fiber mixed solution; add 30 parts by weight of potassium carbonate to the mixed solution, stir ultrasonically for 35 minutes, Potassium and barium chloride take place precipitation reaction, form bamboo fiber-barium carbonate precipitation mixed liquor, add potassium hydroxide 20 weight parts in its mixed liquor, make mixed liquor be alkaline, and add 20 weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com