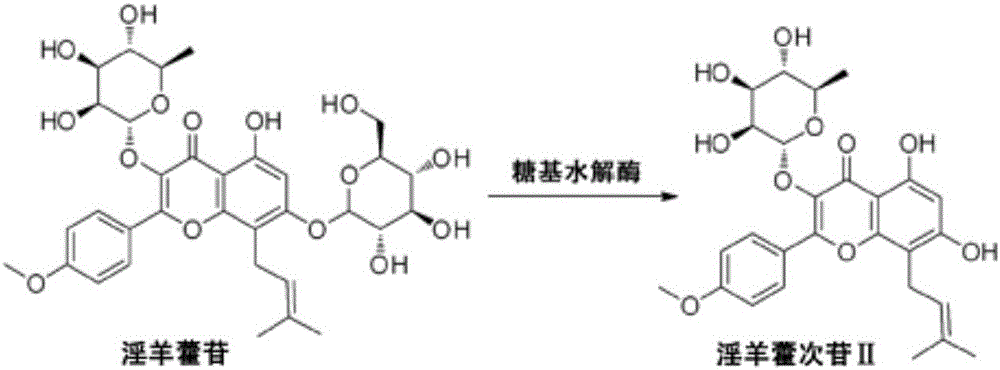

Production process of icariside II

A technology of icariin and production process, which is applied in the field of production process of icariin II, can solve the problems of lack of understanding of glycosyl hydrolase, low hydrolysis efficiency, etc., and achieves low equipment requirements, improved purity, and simplified Effects of purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] A kind of production technology of icariside II:

[0033] (1) First extract icariin monomer from Epimedium: the process steps of extracting icariin monomer from Epimedium are as follows: crush Epimedium to 20-80 mesh, 100g Epimedium pulverized Add 300-800mL ethanol with a mass concentration of 45-85%, heat and reflux for 1-4h to obtain Epimedium crude extract; Epimedium crude extract is dissolved in water and ethyl acetate and separated, and the aqueous phase is extracted with ethyl acetate for 3- 5 times, combined the ethyl acetate phase, washed with saturated brine, dried over anhydrous sodium sulfate, and spin-dried to obtain a dried product; the dried product was heated to reflux with a mixed solvent for 1-4 hours, filtered, and the filter residue was heated to reflux with a mixed solvent for 1-4 hours. 4h, filter, combine the filtrates, and dry to obtain icariin monomer. The mixed solvent is a mixture of water and methanol at a volume ratio of 1:2-3.

[0034] (2)...

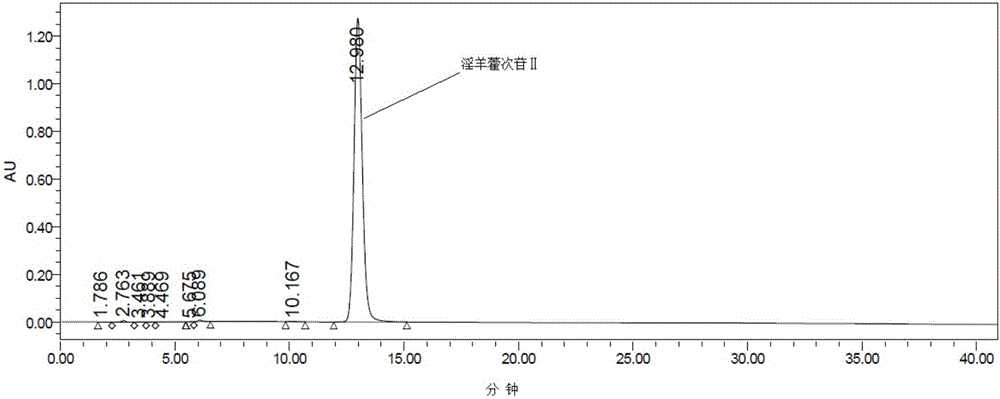

Embodiment 1

[0040] Epimedium (40-60 mesh) 100g, 400ml of 75% ethanol was heated to reflux for 1h to obtain 15.5g Epimedium crude extract (HPLC icariin content 10%), dissolved in 150ml water and 150ml ethyl acetate and The layers were separated, and the aqueous phase was extracted three times with 150 ml of ethyl acetate each time. The ethyl acetate phases were combined, washed with saturated brine, dried over anhydrous sodium sulfate, and spin-dried to obtain 8.5 g of a tan solid. Water: 100ml of mixed solvent of methanol = 1:2 was heated to reflux for 1h, filtered, and the filter residue was refluxed with 100ml of mixed solvent for 1h, the mother liquor was combined twice, spin-dried, and dried to obtain 1.49g light yellow solid (HPLC icariin content 98.5%), yield 96.1%.

Embodiment 2

[0042] Epimedium (20-40 mesh) 100g, 75% ethanol 500ml heating reflux 1h, get 14.5g Epimedium crude extract (HPLC icariin content 10%), dissolve with 150ml water and 150ml ethyl acetate and The layers were separated, and the aqueous phase was extracted three times with 150 ml of ethyl acetate each time. The ethyl acetate phases were combined, washed with saturated brine, dried over anhydrous sodium sulfate, and spin-dried to obtain 8.2 g of a tan solid. Water: 100ml of mixed solvent of methanol = 1:2 was heated to reflux for 1h, filtered, and the filter residue was refluxed with 100ml of mixed solvent for 1h, the mother liquors were combined twice, spin-dried, and dried to obtain 1.35g light yellow solid (HPLC icariin content 98.3%), yield 93.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com