Composite beam type bridge floor continuation device and bridge floor continuation method applied in hollow slab girder bridges

A technology of hollow slab girders and composite beams, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting bridge durability and ride comfort, poor durability of unbonded materials, and failure to achieve unbonded, etc., to achieve Prevention of water seepage and erosion of concrete, easy factory processing, and prevention of water erosion and corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

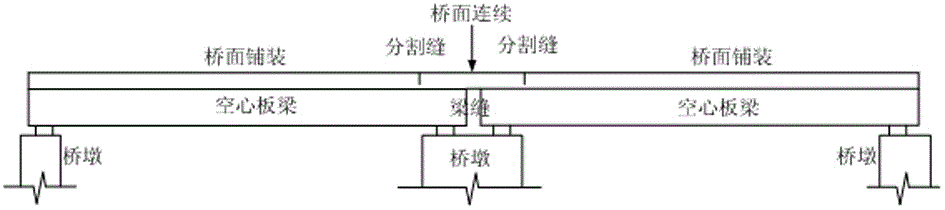

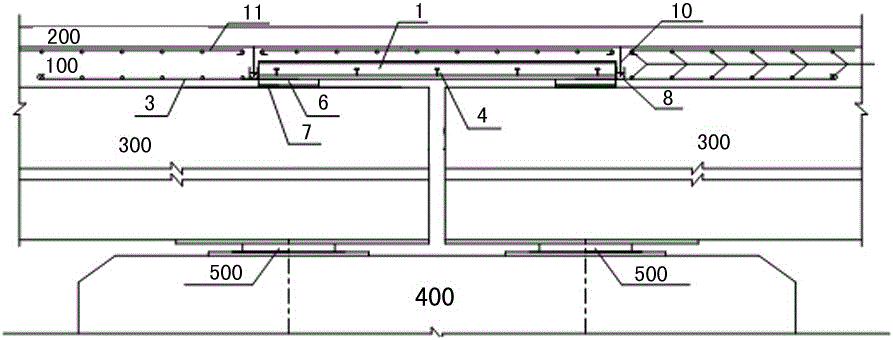

[0044] Embodiment 1, bridge deck continuous device.

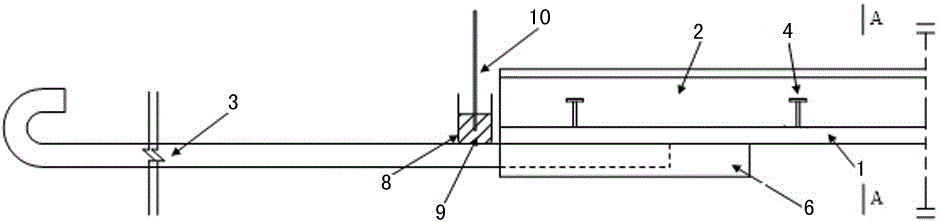

[0045] Refer to attached Figure 3-11 .

[0046] The bridge deck continuous device of the present invention is arranged in the bridge deck pavement reinforced concrete layer 100, the upper layer of the bridge deck pavement reinforced concrete layer 100 is the bridge deck pavement asphalt concrete layer 200, the bridge deck continuous device of the present invention is arranged on the hollow beam On the upper surface of the plate 300, the number 400 in the figure is a bridge pier, and the number 500 is a support.

[0047] The bridge deck continuous device of the present invention comprises steel plate standard section 1, and steel plate standard section 1 adopts 8cm thick steel plate as basic material, considers the convenience of transportation and construction, according to the width of main girder girder of commonly used hollow slab girder bridge, is processed into horizontal length at factory Steel plate standard secti...

Embodiment 2

[0054] Embodiment 2, bridge deck continuous method.

[0055] Refer to attached Figure 3-11 .

[0056] The bridge deck continuous method of the present invention refers to the specific steps of applying the bridge deck continuous device of embodiment 1 to the hollow slab girder bridge, and the bridge deck continuous method can realize the continuous bridge deck of embodiment 1 on the hollow slab girder bridge device, the bridge deck continuous method comprises the following steps:

[0057] 1) The steel plate standard section 1 of the bridge deck continuous device is prefabricated in the factory, including T-shaped ribs 2 and shear nails 4 composed of 5 mm thick steel plates welded on 8 mm thick steel plates to improve the overall rigidity of the structure and strengthen the connection with concrete Then stick the F4 plate 6 on the bottom of both ends of the steel plate. When pasting the F4 plate, the side used for pasting is sodiumized first, and then glued to the bottom edg...

Embodiment 3

[0064] Embodiment 3, finite element analysis of bridge deck continuous device.

[0065] Refer to attached Figure 12 . The simulation of the device of the present invention adopts the large-scale general finite element program ABAQUS 6.12. In addition to the fine simulation geometric model, the distribution and material properties of the steel bars are also simulated strictly according to the design conditions. The simulation process consists of two steps:

[0066] (1) Establish the finite element simulation models of the continuous tie-rod bridge deck and the continuous steel-concrete composite beam deck respectively.

[0067] (2) By applying vehicle loads and temperature effects, simulating the actual bridge loading conditions, and comparing the force calculation results of two types of bridge deck continuous concrete, the effectiveness of the invention in preventing concrete cracking is demonstrated.

[0068] The calculation results of the continuous concrete stress of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com