Method for designing and forming stiffness-controllable bone tumor defect repair implant

A molding method and bone tumor technology, applied in design optimization/simulation, calculation, image data processing, etc., can solve the problems of bone loss, prosthesis loosening, brittle texture, etc. The effect of incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

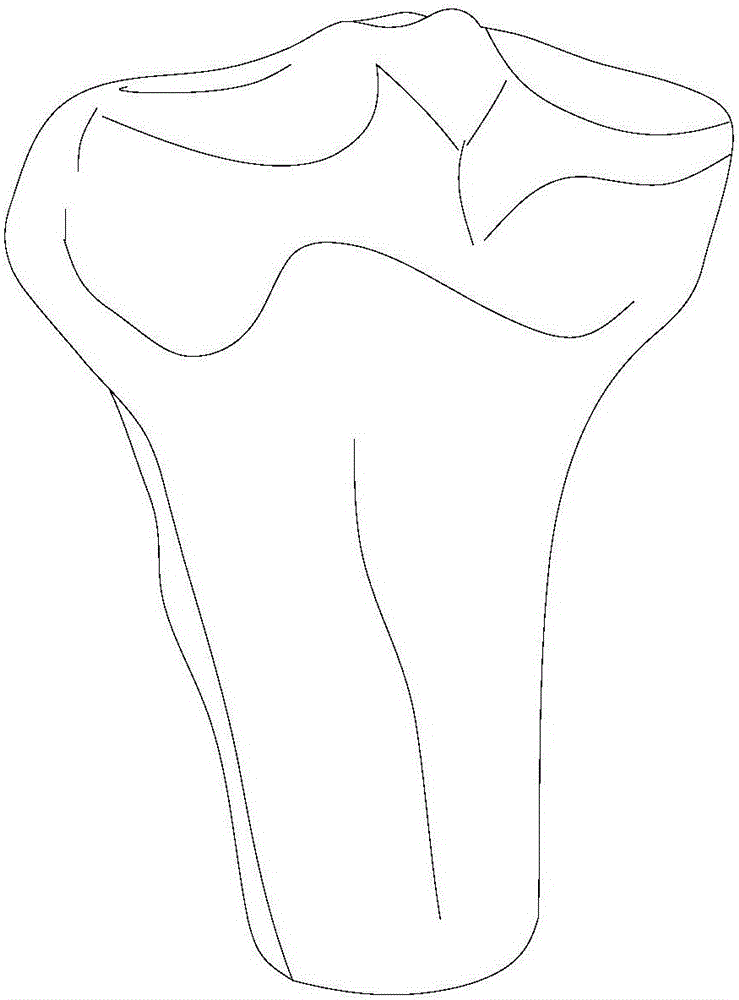

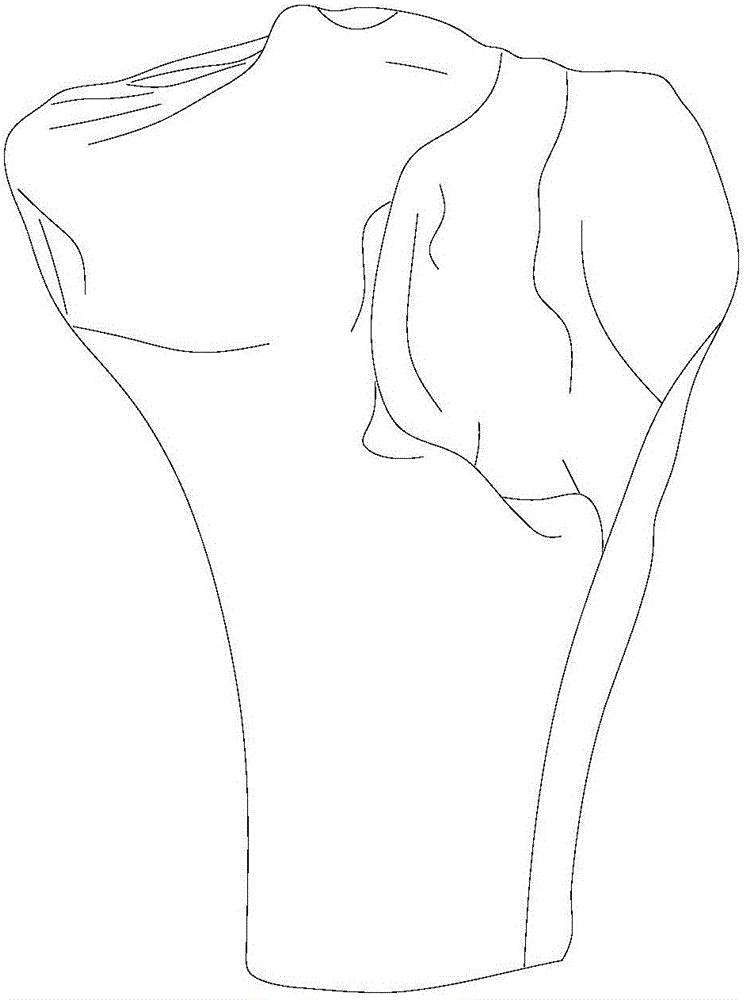

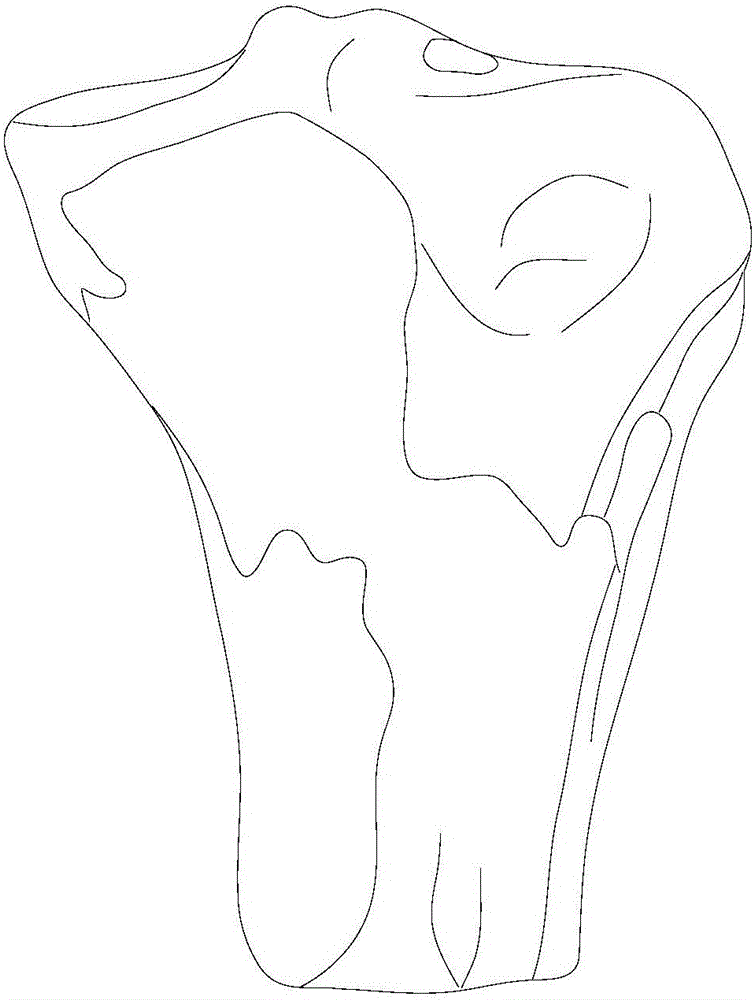

[0023] Such as Figure 1-Figure 5 As shown, a stiffness-controllable bone tumor defect repair implant design and molding method, including the following steps:

[0024] 1) Image data collection and preprocessing: 64-slice spiral CT scanning is performed on the affected side and the corresponding healthy side, and the original tomographic image data of the target part is obtained in Dicom format, and automatically numbered and sorted, and then the original CT image is eliminated by the median filter method. And salt and pepper noise, then use Gauss-Laplace transform to denoise to find the second-order derivative vector, use the zero-crossing point of the second-order derivative to determine and protect the signal edge, which is beneficial to the later image segmentation;

[0025] 2) Reconstruction of the 3D digital model after resection of the ipsilateral tumor and repair of mirror image defects: Import the preprocessed Dicom data into the medical modeling software Mimics, dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com