A coaxial cable production process

A coaxial cable and production process technology, applied in the field of coaxial cable production process, can solve the problems of high production cost, shock absorption effect, poor twisting and tensile performance, etc., and achieve low production cost, excellent heat resistance and anti-aging performance, The effect of reducing the difficulty of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

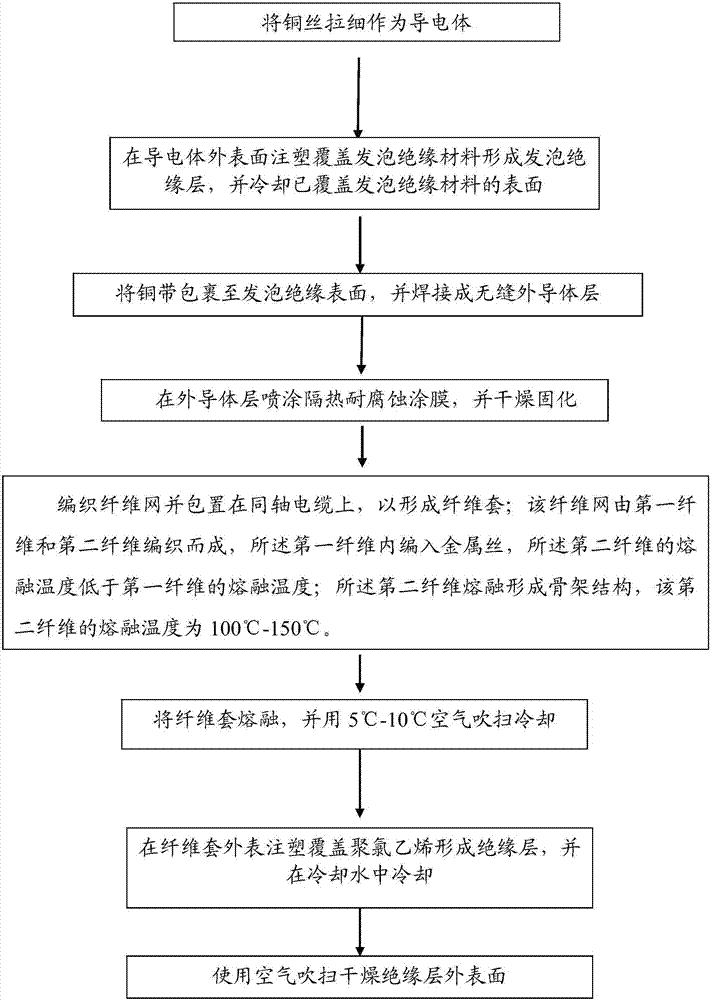

[0033] Embodiment one: the present invention discloses a kind of coaxial cable production technique (see attached figure 1 , 2 , 3, 4, 5), including the following steps:

[0034] 1) copper wire drawing process: drawing copper wire as conductor 1;

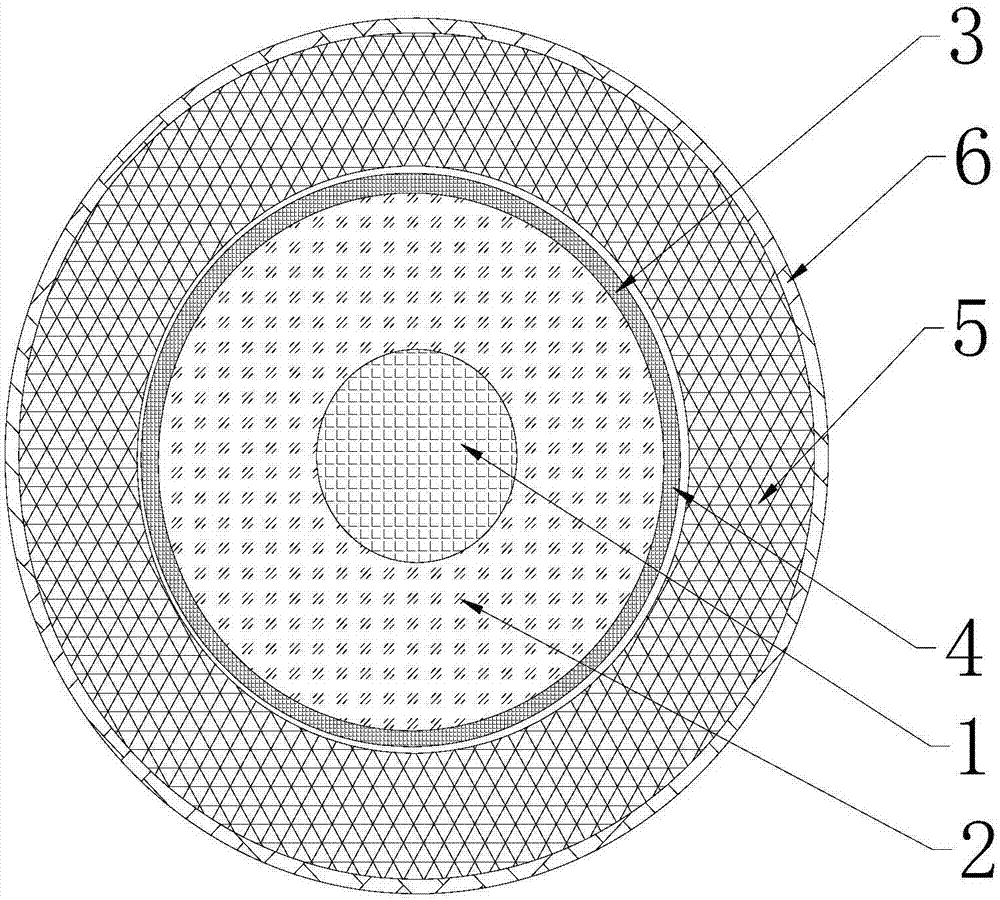

[0035] 2) Foam insulation injection molding and cooling process: injecting and covering the outer surface of the conductor 1 with a foam insulation material to form a foam insulation layer 2, and cooling the surface covered with the foam insulation material;

[0036] 3) Copper tape wrapping and welding process: wrap the copper tape to the foam insulation surface, and weld it into a seamless outer conductor layer 3;

[0037] 4) Spray coating and curing process: spray heat-insulating and corrosion-resistant coating 4 on the outer conductor layer 3, and dry and cure;

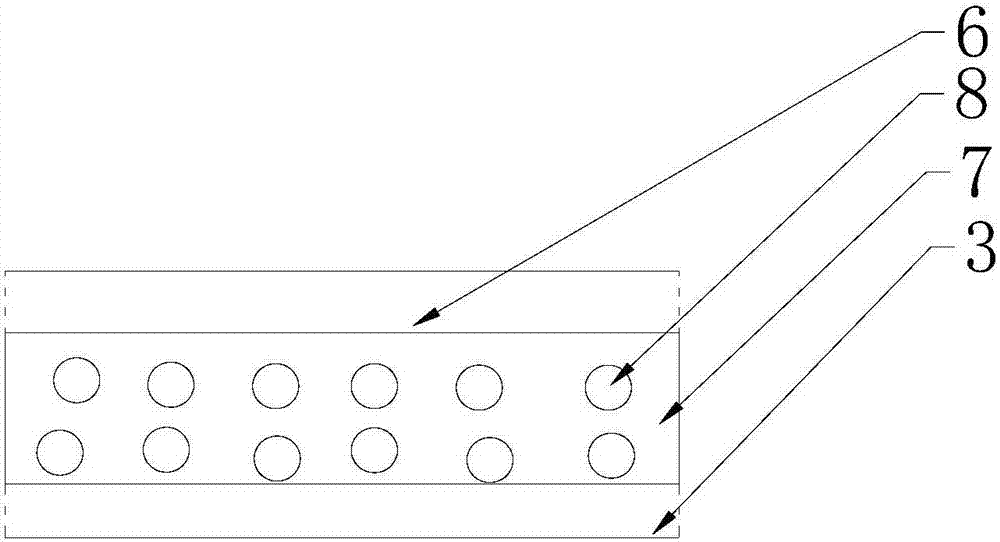

[0038] 5) Sleeve fiber sleeve process: weave fiber net 8 and wrap it on the coaxial cable to form fiber sleeve 5;

[0039] 6) Melting and cooling process: melting th...

Embodiment 2

[0046]Embodiment two: the fiber web 8 in the step 5) and step 6) is woven by the first fiber 51 and the second fiber 52, and the metal wire is braided in the first fiber 51, and the second fiber 52 The melting temperature of the second fiber 52 is lower than the melting temperature of the first fiber 51; the melting temperature of the second fiber 52 is 150° C. to form the skeleton 7 structure. In the melting and cooling process of step 6), the fiber sheath 5 is melted and cooled by blowing air at 5°C. Air purging at 5°C-10°C cools faster and is convenient for cooling with shorter contact time on the assembly line. In the actual production process, the length of the purge equipment and the setting of the nozzle are adjusted according to the flow rate of the assembly line.

[0047] The fiber sheath 5 is melted at a temperature of 150°C. The melting time is 15 minutes. With an external heating temperature of 100°C-150°C and a melting time of 5min-15min, the heating temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com