A kind of organic photovoltaic element and preparation method thereof

An organic photovoltaic and photovoltaic element technology, applied in the field of organic photovoltaic elements and their preparation, can solve the problems of poor crystallization ability, reduce the carrier mobility of organic materials, etc., improve thermal stability and chemical stability, and improve the current carrying capacity. Effect of sub-collection efficiency and energy conversion efficiency, achieving long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

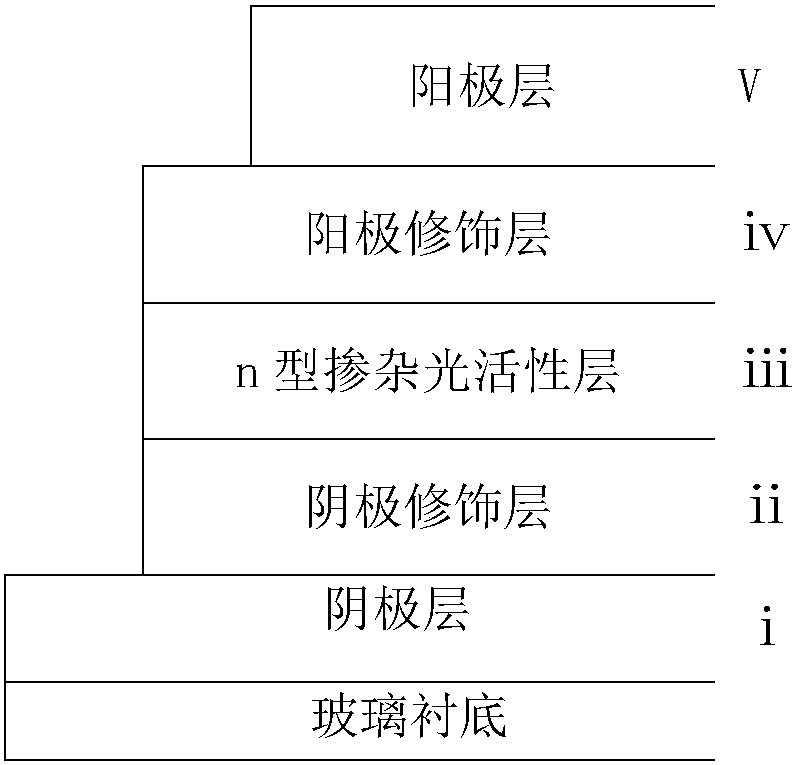

[0046] The preparation structure is ITO with a thickness of 100nm / PEIE with a thickness of 5nm / P3HT:PC with a thickness of 80nm 61 BM:LCV=12:10:0.24 / MoO with thickness of 10nm 3 / A reverse polymer solar cell of Ag with a thickness of 100 nm.

[0047] The reverse polymer solar cell consists of a layer of ITO cathode layer with a thickness of 100nm on a glass substrate, a layer of PEIE film cathode modification layer with a thickness of 5nm deposited on the ITO cathode layer, and a layer of PEIE film cathode modification layer deposited on the PEIE film cathode layer. 80nm thick P3HT: PC 61 BM: LCV thin film n-type doped photoactive layer, one layer is deposited on P3HT:PC 61 BM: MoO with a thickness of 10 nm on the n-type doped photoactive layer of the LCV film 3 Thin film anode modification layer and a layer deposited on MoO 3 A reverse polymer solar cell composed of an Ag anode layer with a thickness of 100 nm on the thin-film anode modified layer.

[0048] The above-mentioned ITO...

Embodiment 2

[0071] The fabricated structure is ITO with a thickness of 100nm / PEIE with a thickness of 5nm / PTB7-Th:PC with a thickness of 120nm 71 BM:PyB=10:15:1 / MoO with a thickness of 10nm 3 / A reverse polymer solar cell of Ag with a thickness of 100 nm.

[0072] The reverse polymer solar cell consists of a layer of ITO cathode layer with a thickness of 100nm on a glass substrate, a layer of PEIE film cathode modification layer with a thickness of 5nm deposited on the ITO cathode layer, and a layer of PEIE film cathode modification layer deposited on the PEIE film cathode layer. 120nm thick PTB7-Th:PC 71 BM: PyB thin film n-type doped photoactive layer, one layer is deposited on PTB7-Th:PC 71 BM: MoO with a thickness of 10 nm on the n-type doped photoactive layer of the PyB film 3 Thin film anode modification layer and a layer deposited on MoO 3 A reverse polymer solar cell composed of an Ag anode layer with a thickness of 100 nm on the thin-film anode modified layer.

[0073] The ITO anode s...

Embodiment 3

[0087] The fabricated structure is Ag with a thickness of 10nm / PEIE with a thickness of 5nm / PTB7-Th with a thickness of 120nm: IEIC:LCV=10:15:0.1 / MoO with a thickness of 10nm 3 / A reverse polymer solar cell of Ag with a thickness of 100 nm.

[0088] The reverse polymer solar cell is composed of a layer of Ag cathode layer with a thickness of 10nm on a glass substrate, a layer of PEIE film cathode modification layer with a thickness of 5nm deposited on the ITO cathode layer, and a layer deposited on the PEIE film cathode modification layer PTB7-Th: IEIC: LCV thin film n-type doped photoactive layer with a thickness of 120 nm on the top, and a layer of MoO with a thickness of 10 nm deposited on the PTB7-Th: IEIC: LCV thin film n-type doped photoactive layer 3 Thin film anode modification layer and a layer deposited on MoO 3 A reverse polymer solar cell composed of an Ag anode layer with a thickness of 100 nm on the thin-film anode modified layer.

[0089] The glass substrate used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com