Integrated automatic control hydraulic servomotor

An oil motor and oil tank technology, applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of reducing the life of hydraulic oil, increasing the amount of maintenance, and high maintenance requirements, so as to reduce the occurrence of failures probability, reduce design complexity, and simplify the effect of equipment wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

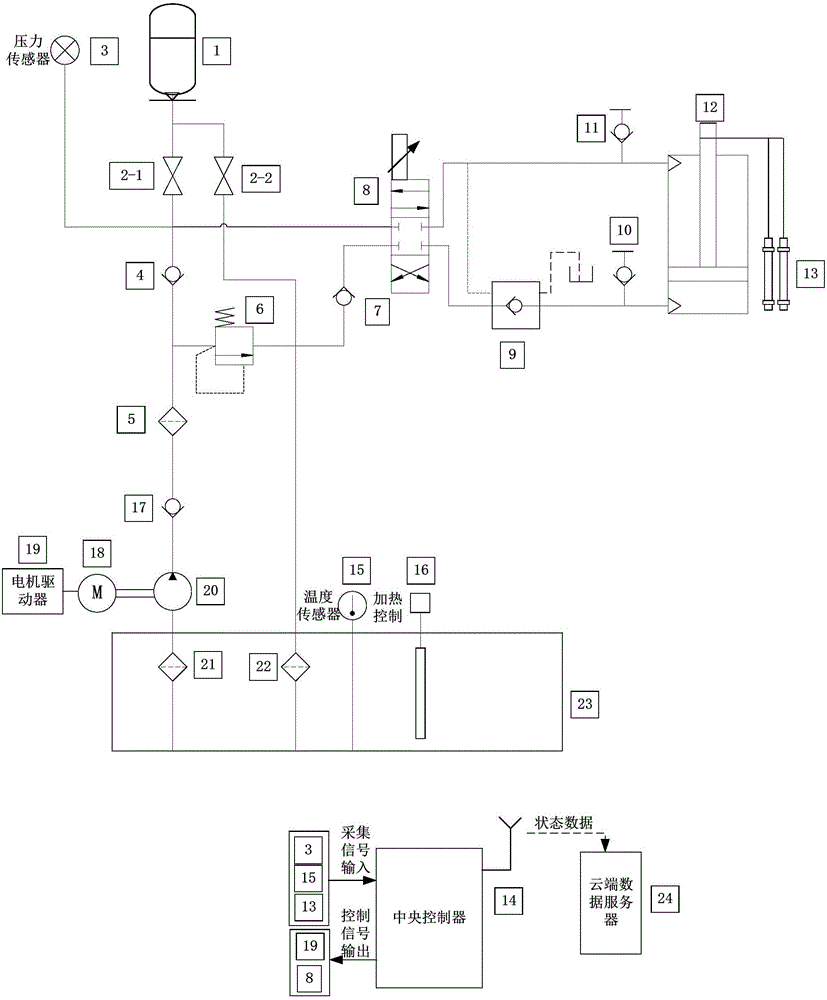

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] see figure 1 , the present invention structurally includes an oil tank 23 and an oil supply pipeline and an oil return pipeline connected to the oil tank 23 through an oil supply filter 21 and an oil return filter 22 respectively, and the oil supply pipeline is respectively connected to the accumulator 1 through an oil pump 20 And the hydraulic cylinder 12, the accumulator 1 is connected to the oil supply pipeline through the normally open oil inlet ball valve 2-1, and is connected to the oil return pipeline through the normally closed oil outlet ball valve 2-2. The oil pump 20 is connected with a motor 18 for driving its action. On the oil supply pipeline at the outlet of the oil pump 20, a check valve 17, a filter 5, and a check valve 4 for preventing oil supply backfilling when the oil pump 20 stops are arranged in sequence. The oil cylinder 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com