Cast part and insert for such a cast part

A technology of inserts and castings, used in engine components, machines/engines, mechanical equipment, etc., to promote isolation, reduce thermal conductivity, and enhance thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

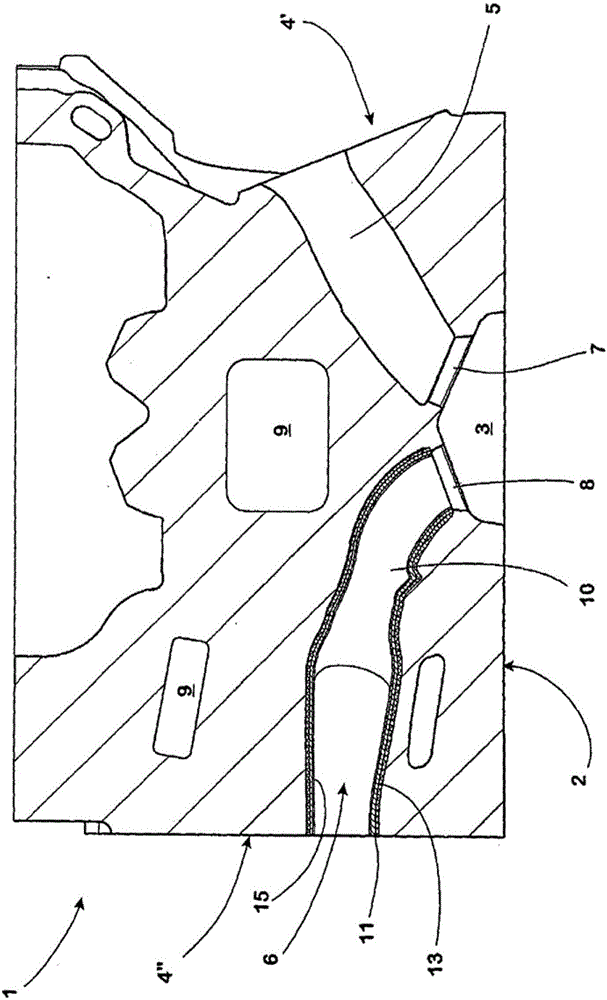

[0065] A cylinder head 1 for a gasoline or diesel engine, cast from the aluminum casting material normally used for this purpose (for example AlSi alloy), has a planar support surface 2 by means of which the cylinder head passes through the necessary A sometimes central piston head seal, not shown here, is placed on the engine block, likewise not shown here, of the respective internal combustion engine. Here, the internal combustion engine has combustion chambers arranged in a row and a piston, likewise not visible here, which moves up and down in it.

[0066] Corresponding to the number of cylinders of the internal combustion engine, a plurality of curved recesses 3 are formed in the bearing surface 2 , which form an upper closure of the combustion chamber of the internal combustion engine in the stroke direction of the piston.

[0067] An inlet channel 5 leading from the longitudinal side 4' (inlet side) of the cylinder head 1 respectively opens into the recess 3, through wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com